In this interview, AZoLifeSciences talks to Dr. Mary Chan about the development of a new ‘smart’ food packaging that is biodegradable and has antimicrobial properties, extending the shelf-life of fresh food.

Please could you introduce yourself and tell us about your background in materials research?

Dr. Mary Chan is presently a professor at the School of Chemical and Biomedical Engineering at the Nanyang Technological University Singapore (NTU Singapore). Dr. Chan-Park’s main research interests are in polymers in nanoscience and biotechnology. She has published extensively, with more than 180 papers in top-tier journals such as Nature Materials, Advanced Materials, Advanced Functional Materials, JACS, Small, Biomaterials, etc.

What is the food packaging you have developed made of?

The natural food packaging is made from a type of corn protein called zein, starch, and other naturally derived biopolymers, infused with a cocktail of natural antimicrobial compounds. These include oil from thyme, a common herb used in cooking, and citric acid, which is commonly found in citrus fruits.

NTU, Harvard scientists create bacteria-killing food packaging that is biodegradable

What is electrospinning and how did you use this process to produce the food packaging?

Electrospinning is an industrial method to produce fibers using electric force to draw charged threads of polymer solutions into tubes.

The food packaging material is produced by electrospinning the zein, the antimicrobial compounds with cellulose, a natural polymer starch that makes up plant cell walls, and acetic acid, which is commonly found in vinegar.

What beneficial qualities does the packaging have compared to traditional food packaging products?

The packaging is designed to release the necessary minuscule amounts of antimicrobial compounds only in response to the presence of additional humidity or bacteria. This ensures that the packaging can endure several exposures, and last for months.

As the compounds combat any bacteria that grow on the surface of the packaging as well as on the food product itself, it has the potential to be used for a large variety of products, including ready-to-eat foods, raw meat, fruits, and vegetables. In an experiment, strawberries that were wrapped in the packaging stayed fresh for seven days before developing mold, compared to counterparts that were kept in mainstream fruit plastic boxes, which only stayed fresh for four days.

How does your packaging protect food from microbes?

In lab experiments, when exposed to an increase in humidity or enzymes from harmful bacteria, the fibers in the packaging have been shown to release the natural antimicrobial compounds, killing common dangerous bacteria that contaminate food, such as E. Coli and Listeria, as well as fungi.

According to the FAO, every year roughly 1.3 billion tonnes of food is wasted globally. How could the packaging’s anti-microbial qualities help to prevent food waste?

Due to the globalization of food supply and attitude shift towards a healthier lifestyle and environmentally friendly food packaging, there is a need to develop biodegradable, non-toxic, and smart/responsive materials to enhance food safety and quality.

The development of scalable synthesis platforms for developing food packaging materials that are composed of nature-derived, biodegradable biopolymers and nature-inspired antimicrobials, coupled with stimuli-triggered approaches will meet the emerging societal needs to reduce food waste and enhance food safety and quality.

Image Credit: Victoria 1/Shutterstock.com

What sorts of food products will this packaging be useful for?

As the compounds combat any bacteria that grow on the surface of the packaging as well as on the food product itself, it has the potential to be used for a large variety of products, including ready-to-eat foods, raw meat, fruits, and vegetables.

What plans are there for commercializing this technology and making it available globally?

We hope to scale up their technology with an industrial partner, with the aim of commercialization within the next few years. We are also currently working on developing other technologies to develop biopolymer-based smart food package materials to enhance food safety and quality.

How do you hope this food packaging will benefit society and lead to a better future?

Sustainable and biodegradable active food packaging, which has inbuilt technology to keep bacteria and fungus at bay, is of great importance to the food industry. It could serve as an environmentally friendly alternative to petroleum-based polymers used in commercial food packaging, such as plastic, which have a significant negative environmental impact.

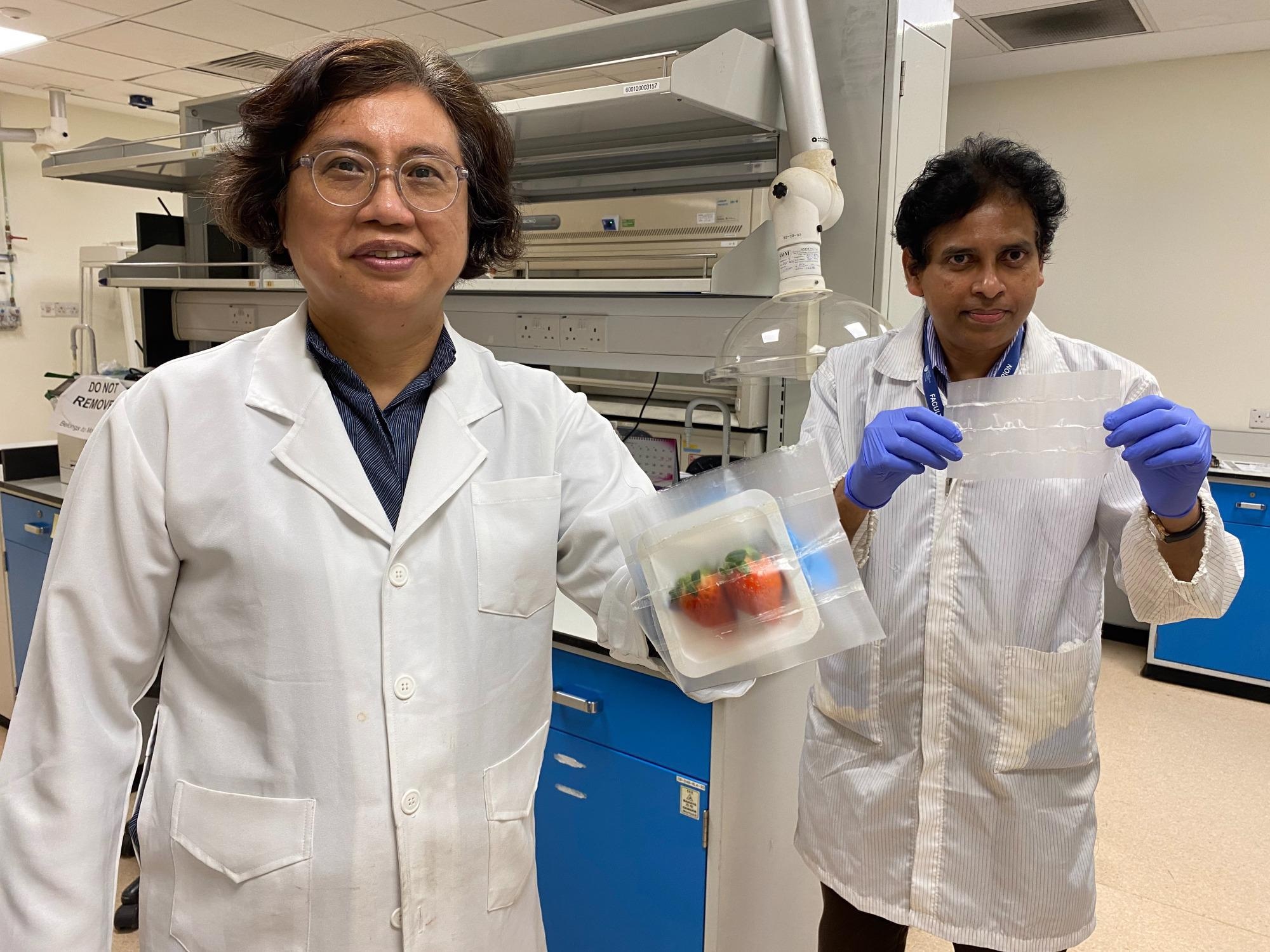

Director of NTU’s Centre of Antimicrobial Bioengineering Professor Mary Chan, and Dr Suresh Kumar Raman Pillai, Principal Research Fellow at NTU’s School of Chemical and Biomedical Engineering. Image Credit: NTU Singapore

Director of NTU’s Centre of Antimicrobial Bioengineering Professor Mary Chan, and Dr Suresh Kumar Raman Pillai, Principal Research Fellow at NTU’s School of Chemical and Biomedical Engineering. Image Credit: NTU Singapore

Where can readers find more information?

About Dr. Mary Chan

Dr. Mary Chan is presently a professor at the School of Chemical and Biomedical Engineering at the Nanyang Technological University Singapore (NTU Singapore). Dr. Chan-Park’s main research interests are in polymers in nanoscience and biotechnology. She has published extensively, with more than 180 papers in top-tier journals such as Nature Materials, Advanced Materials, Advanced Functional Materials, JACS, Small, Biomaterials, etc.

In the area of biomedical polymers, her group has recently developed a novel class of highly effective broad-spectrum antimicrobial coatings which are non-toxic and biocompatible. The findings have recently been published in Nature Materials (2011) and Advanced Materials (2012) and her patents have been used/licensed to companies. Her work in carbon nanotubes focuses mainly on the metallicity-based selection of single-walled carbon nanotubes, solution-based alignment of SWNTs, and nanotube-based composites.

Her group has designed highly effective polymeric dispersing agents and metallicity-based sorting agents (Journal of the American Chem. Soc. 2013, Adv. Funct. Mat. 2008, Chem. Mat. 2009 and 2011). She has been the PI and co-PI of several major projects. From 2008-2013, she was the lead PI of a multi-PI Competitive Research Program on Manufacturability of Carbon-Nanotube Printed Electronics ($10M). This research develops a highly novel method of sorting single-walled carbon nanotubes that is scalable and produces high purity and yield.

Professor Mary Chan contributes actively to the industry and sits on a number of committees and boards. She has recently been elected to be a Fellow of the America Institute of Medical and Biological Engineering. She is also a member of several editorial boards of journals, incl. the American Chemical Society Applied Materials and Interfaces Journal. Professor Mary Chan was the Acting Chair of the School of Chemical and Biomedical Engineering at NTU from 2011-2013. She was also a pioneer of the Chemical and Biomolecular Engineering degree program and the founding Associate Chair (Research & Graduate Studies) and Associate Chair (Research and External Relations) of the new School from 2005-2010 and 2010-2011 respectively.

Prior to joining NTU in 2001, she worked in the chemical industry in Singapore and USA. She was formerly a senior technical manager in Sipix Imaging (CA, USA, now part of E-ink) working on e-paper before joining NTU. She obtained her BEng (Chem) and Ph.D. (polymers) from the National University of Singapore and MIT in 1986 and 1993 respectively.