Discover how lab automation revolutionizes cellular biology, enhancing accuracy and reproducibility in experiments. Explore innovative solutions like automated pipetting and cell monitoring systems, alongside commercial platforms such as StemCellFactory, streamlining processes for greater control, speed, and accuracy.

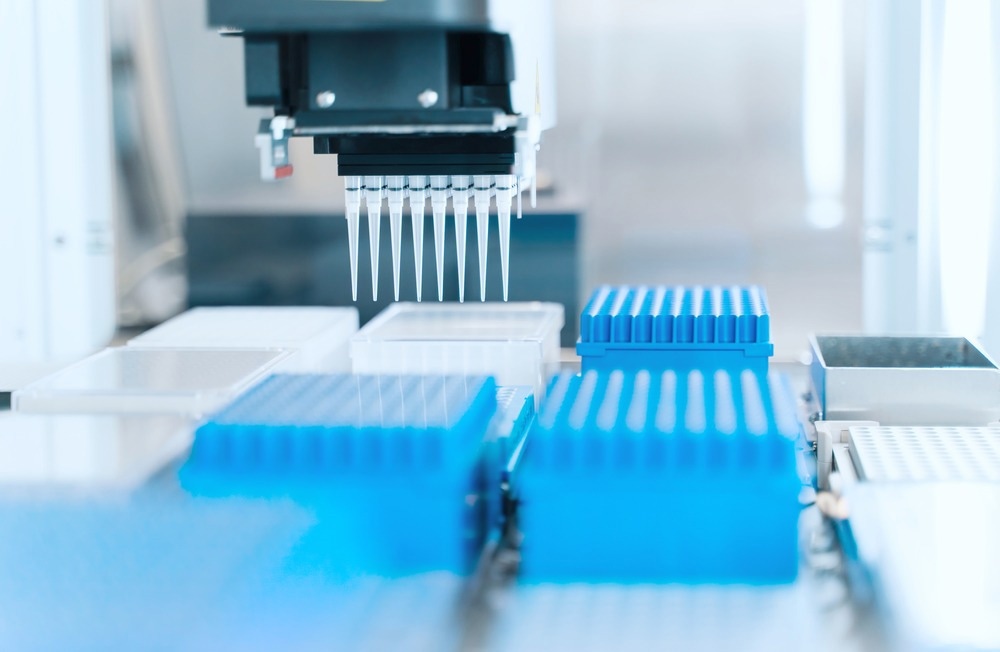

Image Credit: Elpisterra/Shutterstock.com

Cellular biology deals with the study of cell structures and functions.1 Automation in cell culture labs reduces the risk of human errors and subsequently increases the accuracy and reproducibility rates of experiments. Lab automation offers scientists more time to conduct analytical work, rather than being engaged in repetitive tasks without analytical value.2 The advancements in artificial intelligence, robotics, and scientific instruments enabled biomedical companies to manufacture automated cell culture systems that help create an automated lab.3

Automation in Cellular Biology

Considering the rapid developments and advancements of cell-based therapies, it is essential to standardize methods for cellular quality control. Lab automation enables the production of high-quality cell-based products as it reduces the risk of human errors and contamination.

Lab automation has been applied in different aspects of cellular biology experiments. Some automated solutions used in labs that perform cell-based experiments are as follows:

Automated Pipetting:

Pipettes are common tools used in biology and chemistry labs, helping researchers to accurately measure and transfer small volumes of liquids.4 It must be noted that the accuracy of pipetted volume can differ with respect to the calibration and quality of the pipette used. In addition, environmental conditions, such as temperature and density of liquid transferred, also influence the pipetting accuracy.

Automated pipetting is associated with the development and advancements in liquid handling robots. A typical liquid-handling robotic workstation is comprised of robots, a control center, dispensing apparatus, sensors, and washing modules.5 The robot is managed by the control system throughout its activities, i.e., from liquid dispensing to washing.

Automated pipetting systems are used to accelerate the process of transferring accurate and small volumes of chemicals/liquids.3 To date, many companies, including SEED Biosciences, Tecan, Integra Biosciences, SPT Labtech, and Pipetmax, have manufactured automated pipetting systems or pipetting robots. The epMotion automated pipetting systems, manufactured by Eppendorf, Germany, have been used in toxicity studies concerning HaCaT cells.6

Automated pipetting systems experience difficulty in handling viscous liquids.7 Many times, viscous liquid transfer results in the generation of air bubbles or clogging in tubes, valves, and dispensing heads. This clogging occurs due to the accumulation of liquid debris. Automated pipetting systems are equipped with clogging sensors to overcome this shortcoming.3

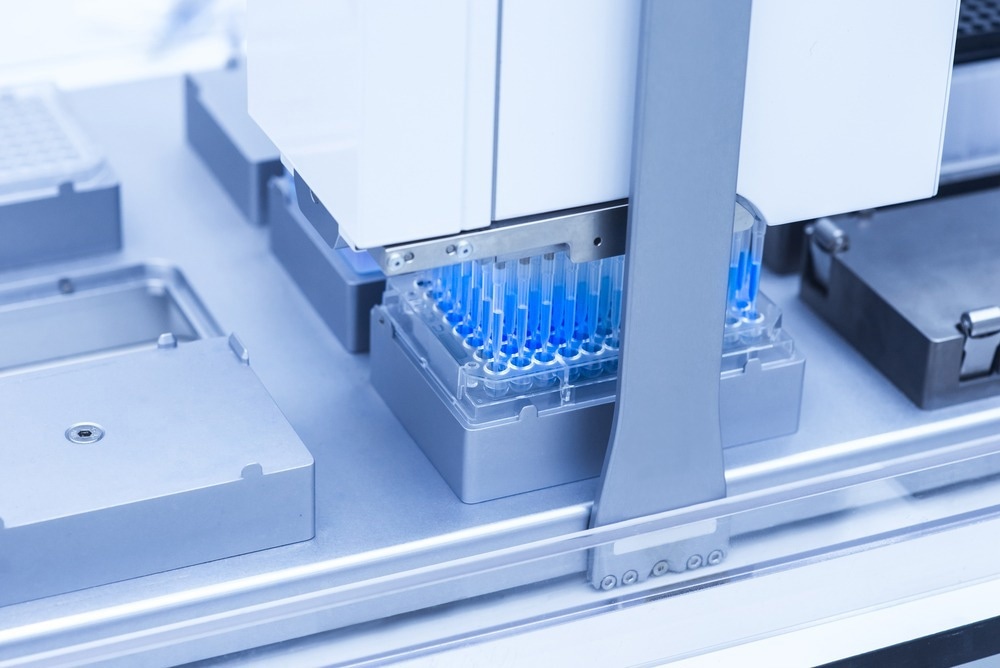

Automation in Cell Monitoring Processes:

Persistent monitoring of cells for a longer period is an important aspect of cellular biology labs. For biomanufacturing companies, it is imperative to characterize and assess the final product for quality and safety. Cell morphology assessments provide important insight into the phenotype and quality.8

An automated cell monitoring system has been developed using algorithmic approaches, such as machine learning models coupled with bioimages.9 This lab automation strategy substantially reduces the need for scientists to assess cell morphology and confluency.

Labtech’s automated cell monitoring system, namely, cellZscope, helps in the assessment of cell quality control. Furthermore, this lab automation system helps examine the effect of drugs or toxins on barrier function. This commercial lab automation solution provides a significant platform to assess cell quality accurately.10

The intelligent cell processing system manufactured by CellQualia helps determine the cell morphology texture. This automated device is a completely closed system that reduces the risk of cellular contamination. Furthermore, CellQualia’s lab automation solution provides an automated cell passage or transferring system and real-time imaging. The media analysis sensors used in in-line process analysis enabled automatic analysis of pH, glucose, and lactic acid.11

Each automated monitoring system differs in the type and number of variables measured. For instance, ImageXpress High-Content Imaging Systems developed by Molecular Devices can monitor cell growth and control environmental conditions (e.g., oxygen humidity and carbon dioxide) throughout the imaging experiments.

In the tissue engineering market, there has been a rapidly increased implementation of lab automation in cell monitoring and screening for quality.3 Milteny Biotech’s CliniMACS Prodigy and Cytiva’s Sefia S-2000 are popular automated systems for cell manufacturing.

Image Credit: Denis Starostin/Shutterstock.com

StemCellFactory, A Commercial Automation Solution in Cellular Biology

The StemCellFactory is a platform that offers lab automation for cell production and screening. This system is engaged with automatic cell reprogramming and expansion of induced pluripotent stem cells (iPSCs), which are used for drug screening and disease modelling.12

StemCellFactory is equipped with many devices that are functionally integrated and modulated through a central control system. Each device used in lab automation has a local software agent. This software functions as a middle interface that extracts hardware heterogeneity. A key feature offered by the StemCellFactory is the automated genome editing process and reprogramming opportunity. The CellCelector system has been installed to identify and isolate clones for clonal expansion on the StemCellFactory.

In the case of genome editing or reprogramming, automation can be applied during the cell culture step. The CellCelector system can detect iPSC colonies via automation. This lab automation system detects optimal iPSC colonies that are subjected to clonal expansion on the StemCellFactory.

Automated genome editing is performed by the Nucleofector. StemCellFactory has been used for the automated cloning of human dermal fibroblasts. This lab automation platform also offers clonal selection and proliferation of primary iPSC clones.13

Advantages of a Commercial Automated Platform

Lab automation has successfully grown rare, precious, and difficult cell types.2 The commercial automation solution, such as the StemCellFactory, offers high throughput screening, reproducible results, and growth behavior monitoring. These automated platforms are equipped with novel software tools that assist in producing controlled patient-derived iPSCs.

Lab automation offers control over a bioprocess, with greater speed and accuracy. Therefore, optimized cellular products can be developed in less time compared to conventional processes. As mentioned above, lab automation service relieves researchers from mind-numbingly repetitive work and saves a significant amount of time, which can be used for performing more analytical and creative work. Furthermore, this system provides better documentation and maintenance of culture. Finally, it provides optimal conditions that result in better yield.

Sources:

- Pentimalli, F., & Giordano, A. (2017) Cell Biology and Genetics. Reference Module in Life Sciences. doi.org/10.1016/B978-0-12-809633-8.12390-8

- Holland, I., & Davies, J.A. (2020) Automation in the Life Science Research Laboratory. Front Bioeng Biotechnol., 8, p. 571777. doi.org/10.3389/fbioe.2020.571777

- Doulgkeroglou, M. et al. (2020) Automation, Monitoring, and Standardization of Cell Product Manufacturing. Frontiers in Bioengineering and Biotechnology, 8, p. 534204. doi.org/10.3389/fbioe.2020.00811

- Guan, X.L., et al. (2023). Assessing variations in manual pipetting: An under-investigated requirement of good laboratory practice. The Journal of Mass Spectrometry and Advances in the Clinical Lab, 30, pp. 25-29. doi.org/10.1016/j.jmsacl.2023.09.001

- Kong, F., et al. (2012). Automatic Liquid Handling for Life Science: A Critical Review of the Current State of the Art. SLAS Technology, 17(3), pp. 169-185. doi.org/10.1177/2211068211435302

- Gancarek, E., Hamels, S., & Art, M. (2014). Reliable and robust automation of Cell Viability Assays with the epMotion® 5075t. Eppendorf Application Technologies. Available at: www.eppendorf.com/.../...tion-Cell-Viability-Assays-epMotion-5075t.pdf.

- Torres-Acosta, M.A., Lye, G.J., & Dikicioglu, D. (2022). Automated liquid-handling operations for robust, resilient, and efficient bio-based laboratory practices. Biochemical Engineering Journal , 188, p. 108713. doi.org/10.1016/j.bej.2022.108713

- Tegtmeyer, M. et al. (2024). High-dimensional phenotyping to define the genetic basis of cellular morphology. Nature Communications, 15(1), pp. 1-12. doi.org/10.1038/s41467-023-44045-w

- Lee, H.J., et al. (2023). Automated cell annotation in multi-cell images using an improved CRF_ID algorithm. Preprint. bioRxiv., 2023.06.07.543949. doi.org/10.1101/2023.06.07.543949

- Automated cell monitoring system. LabTech. https://www.labtech.com/product/cellzscope. 2024;

- Intelligent Cell Processing System. CellQualia. Available at: https://www.cellqualia.com/eng/. 2024;

- Elanzew, A.,et al. (2020). The StemCellFactory: A Modular System Integration for Automated Generation and Expansion of Human Induced Pluripotent Stem Cells. Frontiers in Bioengineering and Biotechnology, 8, p. 580352. doi.org/10.3389/fbioe.2020.580352

- Haupt, S., et al. (2009). Automated selection and collection of pluripotent stem cell colonies using the CellCelector™. Nature Methods, 6(6), iii-iv. doi.org/10.1038/nmeth.f.252

Further Reading

Last Updated: Feb 21, 2024