3D printing can be traced back to 1981 when Hideo Kodama tried to patent a layer-by-layer prototyping system. He was unsuccessful with his patent, as was a French attempt to patent a liquid monomer system around the same time.

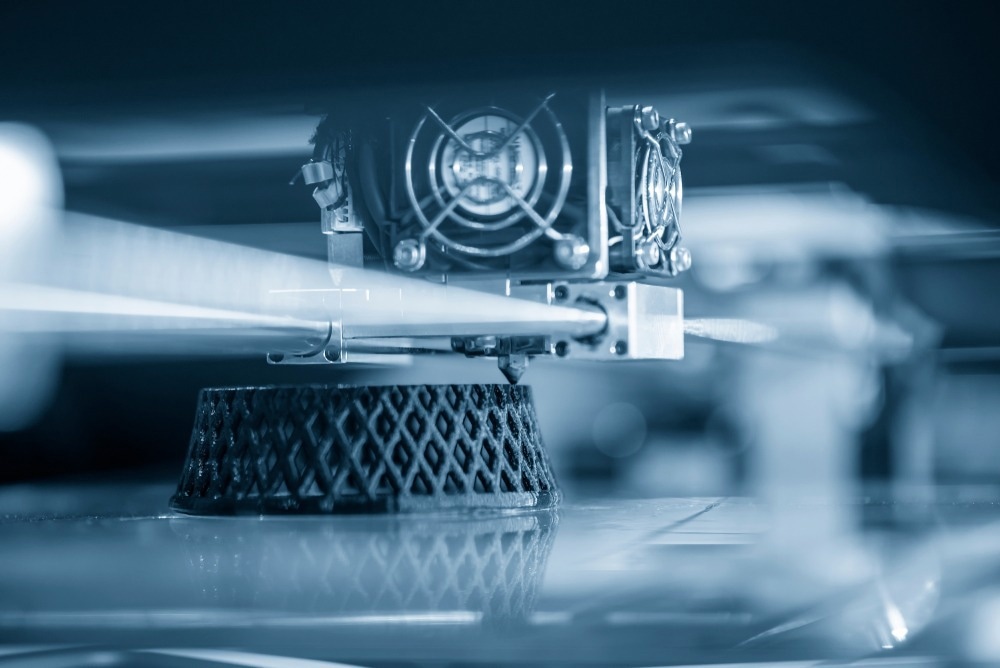

Image Credit: Pixel B/Shutterstock.com

Kodama is, however, considered the inventor of this type of system. In 1986 in the USA, Charles Hull had his Stereolithography patent approved, and in 1988, he founded a 3D Systems Corporation. The same year, Carl Deckard at the University of Texas filed the patent for Selective Laser Sintering (SLS) technology.

During the 1990s and 2000s, the development of CAD tools allowed people to model designs on the computer before printing them. Improved Computer design capabilities, combined with developments in printing technologies, have enabled a massive increase in scope and application for 3D printing. This increased scope includes the 3D printing of molecules. Many areas, such as manufacturing, education, healthcare, computing, aerospace, and others, use these improvements in 3D capability.

3D Molecular Modelling

The first application of 3D printing to creating molecules was in creating 3D models of molecules. It is easier to study and learn about complex molecules by looking at a large-scale model than a 2D representation printed on a page or represented on a computer screen. Aided by improved computer modeling of complex physical shapes, large intricate molecules like DNA and proteins are now relatively easily modeled and printed. Sometimes the number of components and complexity of the structure supports must also be printed to maintain the correct shape of large molecules.

Inevitably the creation of models has meant that people wanted to make actual molecules using this technology. This is now a reality in some applications. 3D printing is important in two main ways for the creation of molecules. Firstly 3D printing can be used to create reactors and chemical handling systems. Secondly, 3D printing can create molecules by combining chemical feedstocks in reactors, possibly created by 3D printing.

Printing of Reactors and Equipment

In analytical and developmental chemistry and biochemistry, small laboratory-scale manufacturing processes are required and are often custom-made for each experiment. This requires research and development labs to employ fabricators such as glassblowers, etc., to build the custom reactors and handling equipment required to carry out bespoke experiments. The fabrication of reactor systems is often time-consuming and expensive.

3D printing is a potential solution for the manufacture of bespoke reactor systems. The advantage of 3d printing is that it can print intricate reactor designs for individual reactors. Where sequential reactions are required, it can create flow reactors or inline chambers to house the individual reactions. This is a cost-effective, quick and flexible way of making specifically designed prototype pilot reactors in-house without requiring expensive tooling for each item manufactured.

This system is very versatile and can be completely digitized, making it easy to repeat, modify and scale up. It has been used at the laboratory scale to manufacture ibuprofen using printed reactors fed with syringe pumps to introduce the ingredients at the right time and in the correct quantities. This system also makes it possible to design mechanical stirrers and reactor walls with specific catalysts and enzymes embedded into them to improve reaction yields and speeds.

This kind of system exists for producing pharmaceuticals but not for creating new molecules. 3D printers can manufacture tablets. Tablets can be made using 3D printers by printing liquid or gel onto a carrier in differing quantities. This process enables the rapid production of personalized medicines with differing content, concentration, and release rates. Pharmacies could produce certain drugs on demand using this kind of system.

Printing Molecules

The ultimate goal of actually printing a new molecule is already possible. It is already possible to react small sections of DNA known as nucleotides together in a microreactor or flow reactor. Subsequently, more nucleotides can be added to the DNA strand to create a new molecule of DNA that could be unique. Another technique uses gold nanoparticles to transport DNA fragments to a reaction site to create new molecules. This system is helpful in nanoelectronics, nanophotonics, and catalysis for creating complex small-scale components.

Connecting two building blocks using 3D printing by initiating a chemical reaction to create a chosen molecule is relatively easy. A significant challenge is to eliminate any unwanted byproducts. However, the close control over the reaction speed, temperature, pressure, etc., means that smaller amounts of precursor are required to achieve a high product yield. The development of increasingly sophisticated analytical equipment such as HPLC, Spectrometry, etc., alongside more precise manufacturing techniques, will expand the limits of 3D printing of molecules. Soon personal custom-made products such as medicines will be possible.

Further Reading

Last Updated: Nov 25, 2022