Biofabrication marries additive manufacturing with physiology. Developing techniques to generate constructs that emulate the architecture of complex systems such as tissues and organs allows for new opportunities in tissue repair, drug toxicity screening, and multi-system modeling. The nomenclature in biofabrication is not standardized due to the developing nature of the field.

This article presents an overview of the most common techniques and the language used. Many of the applications are multi-faceted, drawing from different techniques to generate models.

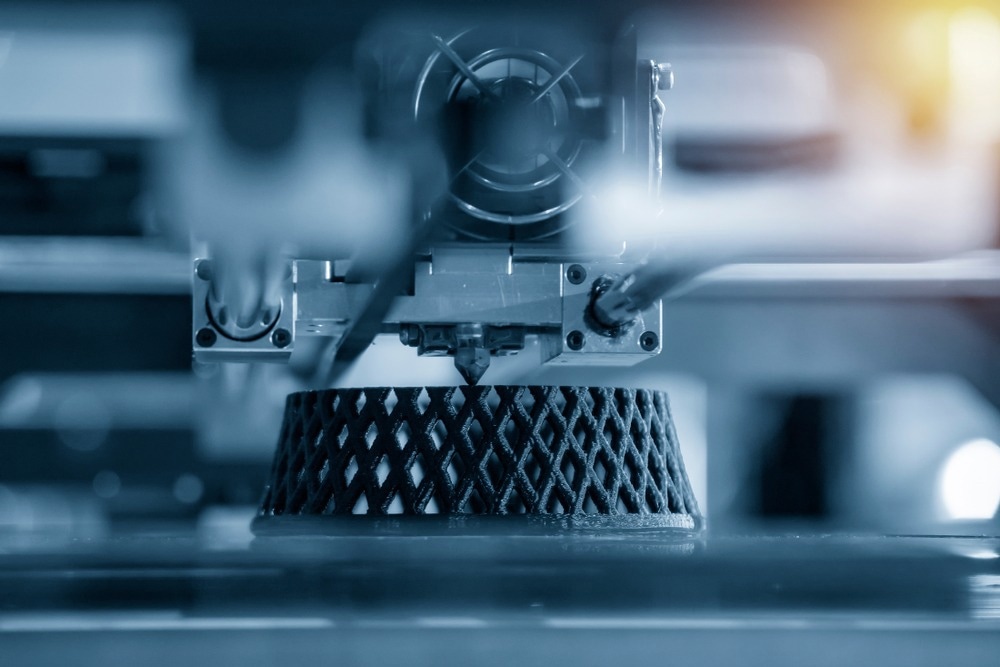

3D Printing

3D printing has opened new avenues to develop synthetic supports to spatially model the architecture of complex biological systems. 3D printing refers solely to specific additive manufacturing technology. The process, reminiscent of conventional printing, uses computer software to define a specific pattern in a powder bed. Binder is directed to the powder bed, solvent binds to the powder, generating a solid material. Another layer of powder is laid down, repeating the process, allowing for solid, hollow objects to be generated. This technique has been manipulated to generate more specific methods.

Image Credit: Pixel B/Shutterstock.com

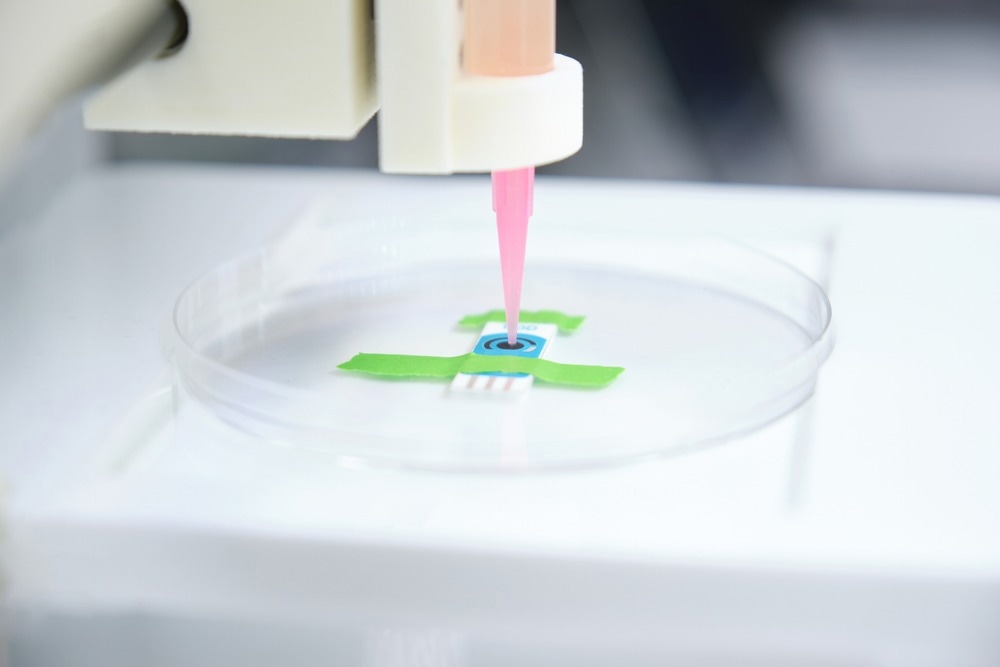

Bio-printing

Bio-printing involves the incorporation of any biological material. Bio-inks refer to the presence of a biological component: cells, aggregates, or microtissues. Bio-printing requires a medium with the appropriate rheological properties: it is sufficiently viscous during printing and solidifies during deposition. This process is called bio-extrusion. At present, this is primarily limited to hydrogels (composed of natural polymers, e.g., collagen, gelatin, hyaluronic acid) which can allow for the viability of the deposited cells but lack the above properties.

Many polymers have been manipulated to alter their properties under shear stress. This facilitates their use in bio-extrusion printing, such as recombinant spider silk and hyaluronic acid with adamantane or cyclodextrin. Peptide binding domains can be grafted onto polymers to confer specific desirable properties. Alginate is often cross-linked with calcium. Alginate generates an environment that protects cells from shear force, while calcium allows for solidification following deposition.

Inkjet and valve-jet are two different mechanisms to deliver the bio-ink in a dropwise fashion. Valve-jet is not subject to nozzle-size restrictions and mitigates shear stress, allowing for the deposition of delicate cells such as human pluripotent stem cells.

Image Credit: Ladanifer/Shutterstock.com

Light-based Technology

Numerous light-based technologies are being investigated for biofabrication. Its advantages over extrusion-based technology are greater resolution, greater viability (no shear stress), and ease of use. Specific Laser Sintering utilizes a laser to trigger the solidification of a powder bed. This process is repeated to build up structures like 3-D printing. Specific Laser Ablation exposes a solid material to a short laser beam pulse, allowing the 3D scaffold to be constructed. This technology has been used in conjunction with bio-inks to generate hexagonal constructs that mimic perfusion in a liver-like model capable of expressing biomarkers for membrane integrity and detoxification.

Laser-Induced Forward Transfer (LIFT) is a laser-assisted method that allows for the encapsulation of cells, unlike the above techniques. A thin layer of metal is vaporized and deposited onto the target substrate containing the biological material of interest in the solution (medium or hydrogels). This process allows for the optimization of cell density and greater resolution. It is, however, hindered by issues related to high cost, low scalability, and demand for very high humidity.

Two-Photon Photoactivation (2-PP) utilizes a tightly regulated laser to polymerize a photosensitive resin. It has been used to generate gelatin-norbornene constructs with demonstrable adhesion, migration, and proliferation. The encapsulation resulted in excellent distribution and density.

Fused Deposition Modeling

Fused Deposition Modeling utilizes molten thermoplastic polymers that are constrained into filaments. The filaments are then deposited to form a layer. The layers are then stacked to generate a 3-D scaffold. The process demands a very high temperature. Caprolactone is the most ubiquitous material due to its low melting temperature and availability at medical grade. It can generate bespoke scaffolds, which is particularly important in tissue engineering to emulate mechanical properties. Pressure Assisted Micro-syringe and wet-spun automated extrusion systems have been developed to overcome the issue of thermal degradation of FDM. They also exhibit higher resolution rates.

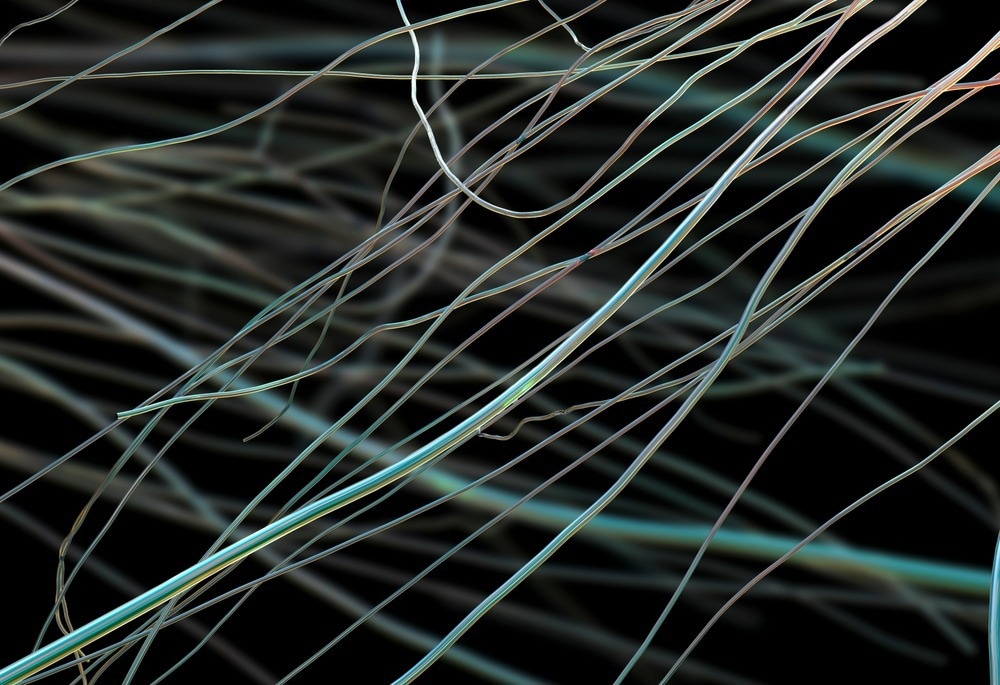

Electrospinning

Electrospinning generates fiber meshes that mimic the extracellular matrix. These are generated by passing biomaterials through an electric field at a specific threshold to manipulate the material into developing an electrohydrodynamic Taylor cone. The newly structured fibers are then collected at a grounded target plate. This has been utilized in conjunction with bio-printing to generate skin constructs. Polycaprolactone and silk sericin were electrospun to generate an epidermis layer. This layer displayed antimicrobial activity, generating a protective barrier against microbial infestation.

Image Credit: Kateryna Kon/Shutterstock.com

Challenges

Numerous challenges must be addressed to overcome the obstacles associated with biofabrication. Scalability and processing time are critical rate-limiting factors. Currently, limited materials possess the appropriate rheological factors to extrude and deposit samples effectively. Foreign body immune responses need to be thoroughly investigated to determine whether materials used in biofabrication are acceptable in transplantation.

There need to be appropriate monitors to ensure that the constructs and encapsulated biological samples are efficacious following transplantation. Physiochemical changes such as shrinking, swelling, deformation, and degradation could impact efficacy in vivo. Computer software is advancing to model and generate molds that can recapitulate the integrity of complex architecture, e.g., vascular tree networks. hIPSCs possess the greatest potential due to their ability to differentiate down different lineages given the appropriate conditions. They are, however, very delicate and subject to transformation. It is necessary to stringently monitor and validate processing to ensure they differentiate and proliferate appropriately.

Conclusions

Biofabrication adapts many established methods from other industries to manipulate amenable materials into suitable constructs to encapsulate or support the development of biological materials. Different techniques present different advantages and disadvantages and are often used in a complementary fashion. Scalability remains a pertinent issue: to develop a material capable of extrusion and deposition with the physiochemical characteristics to support biological viability. Collaboration between process engineering, materials chemistry, and life sciences is critical to overcoming these issues to develop, deliver, and monitor biofabricated constructs and reach therapeutic efficacy.

Sources

- Moroni, L., Boland, T., et al. (2018) ‘Biofabrication: A Guide to Technology and Terminology’, Trends in Biotechnology, 36(4), pp. 384–402. doi: 10.1016/j.tibtech.2017.10.015.

- Moroni, L., Burdick, J. A., et al. (2018) ‘Biofabrication strategies for 3D in vitro models and regenerative medicine’, Nature reviews. Materials. 2018/04/26, 3(5), pp. 21–37. doi: 10.1038/s41578-018-0006-y.

- Ramos, T. and Moroni, L. (2019) ‘Tissue Engineering and Regenerative Medicine 2019: The Role of Biofabrication—A Year in Review’, Tissue Engineering Part C: Methods, 26(2), pp. 91–106. doi: 10.1089/ten.tec.2019.0344.

Further Reading