Attenuated total reflection (ATR) is a sampling technique used alongside traditional infrared spectroscopy, which ultimately qualifies samples to be observed directly in either solid or liquid state, without additional preparation. FTIR stands for ‘Fourier-transform infrared’ spectroscopy: a technique that can be used to procure an infrared spectrum of either the emission or absorption of a liquid, solid, or gas sample.

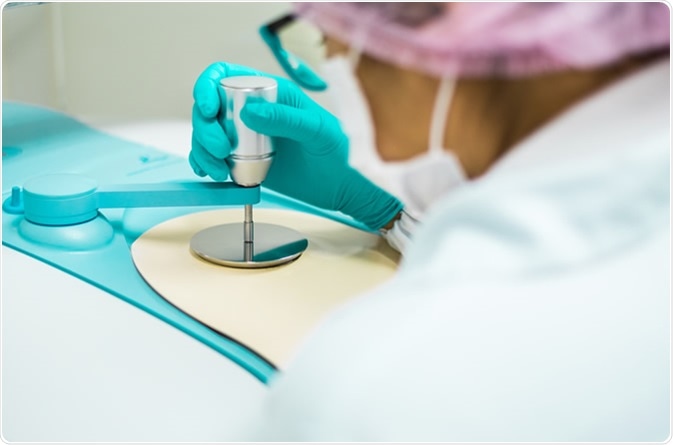

Chemist testing raw material with FTIR spectrometer, quality control laboratory in the pharmaceutical industry. - Image Credit: SUKJAI PHOTO/Shutterstock.com

Attenuated total reflection (ATR) is a sampling technique used alongside traditional infrared spectroscopy, which ultimately qualifies samples to be observed directly in either solid or liquid state, without additional preparation. FTIR stands for ‘Fourier-transform infrared’ spectroscopy: a technique that can be used to procure an infrared spectrum of either the emission or absorption of a liquid, solid, or gas sample.

An FTIR spectrometer synchronously collects the data of high-spectral-resolution over an extensive range. This is advantageous over the traditional dispersive spectrometer which only measures the spectral intensity over a much smaller range of wavelengths at any one time. The term ‘Fourier-transform infrared spectroscopy’ is based upon the Fourier transform process, which is required to convert the raw data into spectra.

What are the principles of attenuated total reflection (ATR)?

An attenuated total reflection accessory functions by quantifying the changes that happen to an internally-reflected infrared beam, once it comes into contact with the chosen sample. To do this, an infrared beam is focused onto a crystal with a high refractive index at a set angle.

The resulting internal reflections create a transient wave that reaches beyond the outer surface of the optically dense crystal, and then into the sample which is held in contact with it.

This initial wave only protrudes by a couple of microns (between 0.5 µ and 5 µ) beyond the surface of the crystal, and into the sample itself. Therefore, there must be decent contact made between the chosen sample and the surface of the crystal. In the parts of the spectrum where the sample absorbs energy, the wave will be either altered or attenuated.

The final attenuated energy from each wave is guided back to the original infrared beam, which subsequently leaves via the other side of the crystal and is passed into the spectrometer’s detector. The system then uses this data to generate an infrared spectrum.

What are the principles of ‘Fourier-transform infrared’ spectroscopy (FITR)?

FTIR (otherwise known as ‘process FTIR’) is a new field that could potentially have a rather strong impact on a variety of industries - primarily by using more efficient materials and energy resources, potentially reduced waste, improved quality of the final product, as well as the reduced environmental pollutants.

FTIR is a complex concept, with each additional application unveiling a variety of questions on subjects such as operating environment, material compatibility, appropriate spectral bands for analysis, accessing samples, as well as optimal quantification methods.

In a majority of cases, it is necessary to assemble a set of samples to use in both the development and testing of the system’s calibration. An initial calibration can usually be decided by the vendor of said system or instrument. It is desirable to have a development system of their own for both in developing the preliminary calibration, as well as for maintaining the system support. This is notably important if there is a shift in the process of manufacture that could need the development of a new calibration.

The abundance of data made available and the considerable power of FTIR systems will enable us to continually fine-tune the sample analysis to keep up with adaptations made to the manufacturing process. Therefore, process FTIR can be considered a new way of both taking care of and controlling the manufacturing process.

Primary uses of ATF-FTIR

This technique can be used to analyze biological samples in a cheaper, more economical manner. The significant cost of substrates is a well-known obstacle when it comes to the introduction of bio-spectroscopy into routine laboratory/clinical practice. As a versatile and cheaper substrate, readily available aluminum foil has been shown in experiments to repeatedly compete with low emissivity, gold-coated, and glass slides used for cytological and histological specimen analysis by ATR-FTIR.

The featureless/low background signal given off by aluminum foil facilitates the production of traditional infrared or Raman spectra, without any interference with the substrate itself, and without sacrificing relevant fingerprint biochemical data of the specimen – even for incredibly thin samples (i.e. approximately 2 μm).

The aluminum foil has been previously found to behave either just as efficiently as (or even better than) the low emissivity or gold-coated slides. Albeit transmission FTIR is not possible on aluminum foil, past studies demonstrate that this foil is a potentially inexpensive, versatile, and readily available substrate that could one day be suitable for ATR-FTIR analysis of a variety of biological samples.

To conclude, the characteristics of aluminum foil demonstrated in previous ATR-FTIR studies could soon promote a progression towards more accessible substrates, some of which can be readily applied in either clinical or research milieus.

ATR Introduction | FT-IR Basics

Further Reading

Last Updated: Oct 12, 2021