A research team from MIT and the Indian Institute of Technology Madras have created organoids, which are small quantities of self-organizing brain tissue, in a tiny 3D-printed system that helps them observe as they grow and develop. The study has been published in AIP Publishing’s Biomicrofluidics journal.

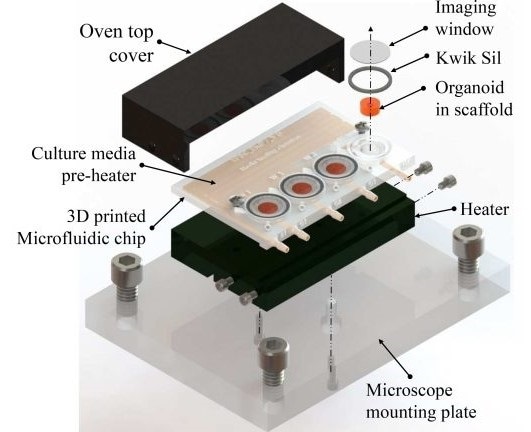

A 3D-printed microfluidic bioreactor for organ-on-chip cell culture. Image Credit: Ikram Khan.

Commercial culture dishes, with several wells in a glass-bottomed plate positioned under a microscope, are currently used for observing the growth of organoids in real time. Such plates are expensive and can only be used with certain microscopes. They prevent the flow or replenishment of a nutrient medium to the developing tissue.

Recent developments have made use of a method called microfluidics, in which a nutrient medium is supplied through small tubes attached to a tiny chip or platform. But these microfluidic instruments are costly and difficult to produce.

The latest breakthrough employs 3D printing to produce an easily customizable and reusable platform that costs just around $5 per unit to design. The design comprises imaging wells for the developing organoids and microfluidic channels to offer a nutrient medium as well as preheating that promotes the growth of tissues.

The 3D-printed device was made from a biocompatible resin that is also used in dental surgery. To cure the printed chip, it was exposed to UV light and then sterilized before placing the live cells in the wells. Once the top of the wells was sealed with a glass slide, the nutrient medium, and the drugs for the analysis were added via small inlet ports.

Our design costs are significantly lower than traditional petri dish- or spin-bioreactor-based organoid culture products. In addition, the chip can be washed with distilled water, dried, and autoclaved and is, therefore, reusable.”

Ikram Khan, Study Author, Indian Institute of Technology Madras

The new device was tested with organoids extracted from human cells. With the help of a microscope, the researchers examined the developing brain organoids and effectively monitored their development and growth for seven days.

A ventricle or cavity, formed in the small part of brain tissue and surrounded by a self-organizing structure, resembled a growing neocortex.

Within the core of the organoid, the number of cells that died during this one-week duration was lower in the 3D-printed system than in normal culture conditions. According to the researchers, their cell design protects the tiny developing brain.

One advantage offered by our microfluidic device is that it allows constant perfusion of the culture chamber, which more closely mimics a physiological tissue perfusion than conventional culture, and thus reduces cell death at the organoid core.”

Ikram Khan, Study Author, Indian Institute of Technology Madras

The researchers hope to expand the capability of the device by increasing the number of available wells. Other upgrades would enable the integration of additional instruments into the design.

Source:

Journal reference:

Khan, I., et al. (2021) A low-cost 3D printed microfluidic bioreactor and imaging chamber for live-organoid imaging. Biomicrofluidics. doi.org/10.1063/5.0041027.