Scientists reveal that increased salt content of whey—the leftover watery part of milk following cheesemaking—makes it one of the most polluting byproducts in the food processing industry.

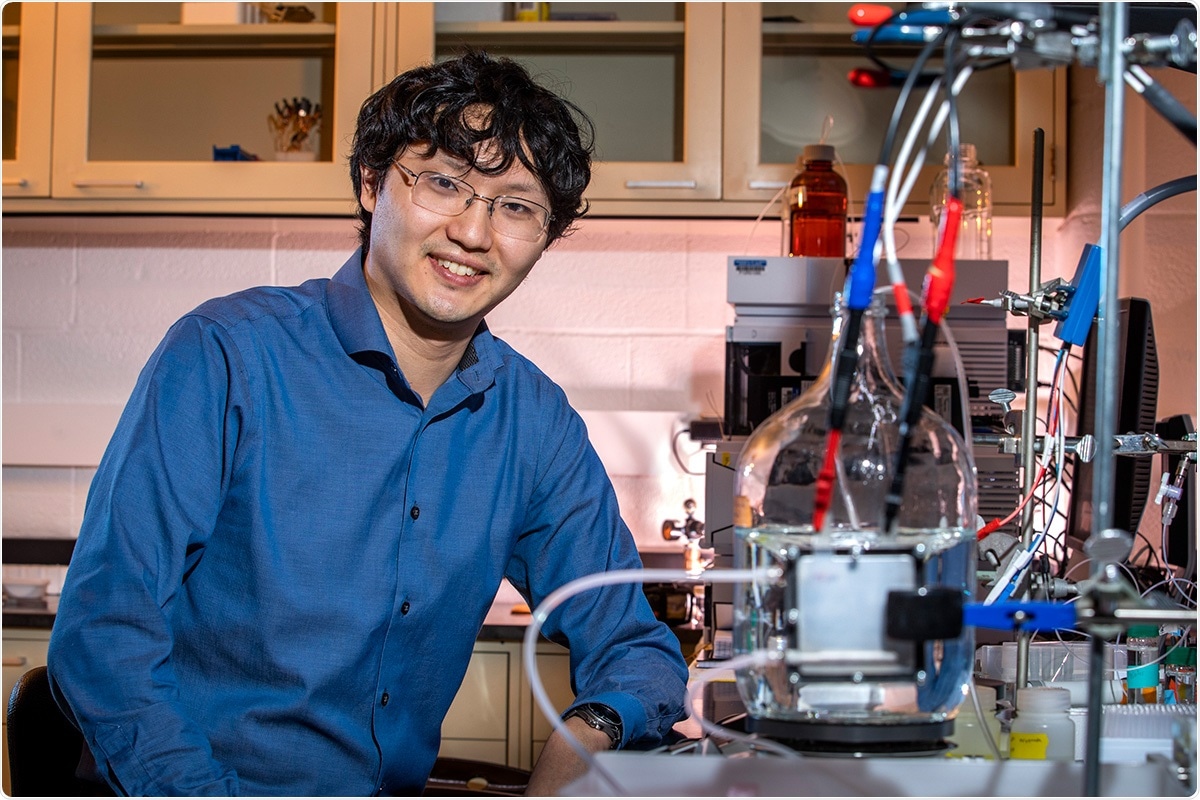

Illinois chemical and biomolecular engineering professor Xiao Su led a team of researchers who found an economical and sustainable method to process excess dairy whey—one of the food manufacturing industry’s largest polluters. Image Credit: Photo by Fred Zwicky.

In recent research, chemists elaborated the first electrochemical redox desalination method employed in the food industry, eliminating and recycling around 99% of excess salt from whey at the same time refining more than 98% of whey’s useful protein content.

The U.S. Department of Agriculture reports intake of cheese increased in recent years, and projections estimate its persistent growth. The research reveals that cheese production contributes around 83% of the total waste stream in the dairy industry.

This environmental damage, in addition to a quickly heightening population need for sustainable food systems, motivated University of Illinois Urbana-Champaign chemical and biomolecular engineering professor Xiao Su to address this challenge through state-of-the-art electrochemical technologies.

The desalination method carried out in this research uses around 73% less energy and functions at 62% of the operating cost linked with traditional desalination systems, stated the scientists. The observations of the research led by Illinois graduate student Nayeong Kim were published in the Chemical Engineering Journal.

Although excess whey is wracked with several environmental waste problems, the food industry also recognizes it as a valuable nutrient source. By demineralizing the highly concentrated salts in whey waste in a sustainable manner, we can eliminate one of the environmental hazards associated with dairy processing while simultaneously unlocking access to the valuable protein resource found in whey waste.”

Xiao Su, Professor, Chemical and Biomolecular Engineering, University of Illinois Urbana-Champaign

Su and his associates addressed this challenge by introducing a chemical redox-coupled dialysis system—a device similar to a battery cell. The process consists of two independently controllable channels for the whey waste and the electrodes, separated by a pair of ion-exchange membranes. Su added that the process permits continuous desalination through a reversible redox reaction.

Our system recovers valuable whey proteins without the risk of protein aggregation or denaturation. Also, the molecular size of redox species is larger than the membrane pore size, meaning it cannot cross over the membrane to contaminate the purified proteins. I believe that the redox-mediated electrodialysis system can revolutionize the food industry by tackling coupled environmental and nutrition crises.”

Nayeong Kim, Graduate Student, University of Illinois Urbana-Champaign

During the protein purification process, positively charged sodium ions relocate from the feed to the redox channel and become chemically reduced at the negative electrode. The negatively charged chloride ions migrate to the redox channel when the reduced ions are oxidized at the positive electrode. This results in a sustainable regeneration of the redox couple.

The research reveals that the redox channel can sustain its electrolyte concentration by discharging the removed ions to the feed channel, and recovered sodium chloride can be repurposed to season cheese, thereby making the process a net-zero waste one.

Remarkably, the performance of protein purification and salt recovery was maintained over multiple cycles, demonstrating outstanding stability and cyclability. Overall, our redox-electrochemical process offers a sustainable and electrified platform for the recovery of valuable proteins from dairy production waste, with envisioned integration with renewable electricity in the future.”

Xiao Su, Professor, Chemical and Biomolecular Engineering, University of Illinois Urbana-Champaign

“We hope this will be the start of research into sustainable food manufacturing in general,” Su further added.

Source:

Journal reference:

Kim, N., et al. (2021) Redox-mediated electrochemical desalination for waste valorization in dairy production. Chemical Engineering Journal. doi.org/10.1016/j.cej.2021.131082.