In this interview, we speak to Karen Schuett, co-founder, and CEO of Livestock Water Recycling, about their technology and how they are helping to save the planet through recycling clean water back from manure slurry.

Please could you introduce yourself and tell us about your role at Livestock Water Recycling?

My name is Karen Schuett and I am the co-founder and CEO of Livestock Water Recycling (LWR).

We are the innovators of a technology that creates value for food producers by reducing the expense and impact of waste liquids while accessing the value locked inside. Our PLANT System has become the most sought-after sustainability solution in the world by global protein producers looking to grow more crops and produce more food using less money and fewer resources, and renewable natural gas producers looking to replace energy crops with concentrated bio-waste.

With many consumers demanding transparency, and at the height of the farm-to-table social movement, our technology is designed to help food producers break free from resource and regulatory constraints to do MORE with less. They can create MORE protein, using MORE effective natural fertilizers, to grow MORE crops, and irrigate these crops with MORE reusable water.

What are some of the missions at Livestock Water Recycling and how are you trying to achieve them?

The waste from our global food systems has impacted our planet. Waste does not exist in nature. Ecosystems reuse everything that grows in a never-ending cycle of efficiency and purpose. This idea inspired our desire to use food production waste more efficiently and sustainably. Our vision of lagoon-free food production transforms our traditional food production into regenerative and restorative circular food systems around the world.

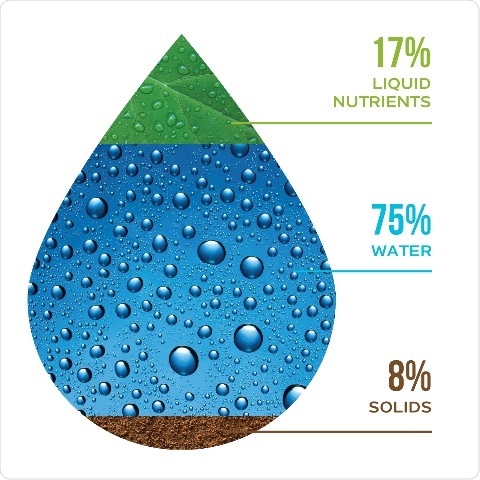

This novel on-farm fertilizer PLANT segregates and concentrates nutrients with the power to recycle clean water back from manure slurry. As the most affordable solution on the market to eliminate manure lagoons, this technology addresses greenhouse gas emissions and nutrient runoff, while significantly reducing groundwater withdrawals.

PLANT builds long-term resilience for farmers, generating new economic opportunities for the farm, which benefits the environment, and protects communities from the severe consequences of food production waste. All this while helping farmers produce the most environmentally friendly and sustainable milk and meat in the world.

What is manure and what are some of the benefits of manure to crops and plants?

Manure slurry is a valuable renewable resource-rich in nitrogen, phosphorus, and potassium. It is highly rich in organic matter and improves soil fertility, carbon sequestration, and water holding capacity. The management of this liquid in storage lagoons and holding tanks is one of the most difficult, expensive, and potentially limiting problems facing the agricultural industry today.

While there is inherent value in manure slurry, the recovery of this value is impeded by the dilute nature of the liquids and the co-mingling of the fertilizers and we are excited to unlock that value for producers.

You are a global leader in manure treatment technology. How can you ‘treat’ manure and what are the benefits of doing this for farmers?

Our patented process concentrates fertilizer nutrients and recycles clean water from manure; all parts of the manure are reused, and the value is retained. This cost-effective solution helps farms deal with increasing government regulations and water shortages while saving money on manure handling costs.

This state-of-the-art manure treatment platform increases farm revenues through increased crop yields of 30-50%, increased herd sizes, improved animal health, and a safer, healthier work environment for employees. Manure odors and freshwater withdrawals are reduced, surface water is protected from nutrient runoff, and greenhouse gas emissions are reduced by up to 81.5%!

This technology also plays a key role in the biogas sector. Renewable Natural Gas is a carbon-neutral, sustainable energy source created by the digestible volatile solids in organic matter that can be converted into methane gas. LWR’s patented particle extraction system concentrates 80% of Volatile Solids. This represents a massive opportunity to produce more biogas with fewer resources. We have also seen an exciting value proposition when it comes to replacing energy crops with these concentrated manure solids.

Using data and artificial intelligence to predictively optimize this ground-breaking technology’s ability to improve biogas outputs from manure and food waste represents the next stage in our evolution towards enhanced circular and sustainable livestock food production.

Other benefits of our technology include:

- Improved operating profit margins

- Possible herd expansion without the acquisition of more land

- Eliminated water shortages

- Reduced manure footprint by up to 75%

- Strategic control of nutrient application

- New, value-add revenue stream

- Increased milk value through cleanliness of barns

- Increased pregnancy rates

- Healthier herd

- Happier employees

- Concentrated liquids that can be hauled further at a reduced expense

- Controlled lagoon capacity

- Eliminated odor and improved community relations

- Conserved water that was previously lost to evaporation

- Reduced field compaction

- Increased fertilizer value of manure

- Reduced commercial fertilizer expenses

- Increased crop yields

- Farmers save time spent hauling, spreading, and managing dilute liquids

Please can you tell us more about your LWR plant system and how it works?

LWR’s manure treatment process takes into account the unique composition of manure liquids. The key to our system design, and what makes what we do so unique, is our ability to treat manure in an environmentally safe way that allows for isolation, concentration, and reuse of valuable nutrients.

Typical treatment results are:

- A concentrated solid fertilizer that contains essential micronutrients, organics, organic nitrogen, and phosphorous that is easily exported to areas of fertilizer demand.

- An ammonium and potassium liquid that can be directly applied to growing crops. Isolating the ammonia captures the nutrient value while eliminating vapor emissions and odor.

- Clean, potable water that can be reused for cleaning, irrigating, or release into the environment.

Image Credit: Livestock Water Recycling

We found that the key is to sequentially remove large to fine particles from the water stream which required chemical conditioning. Traditional water treatment often involves the removal of contaminants to take them off-site for disposal. This was not an option for the livestock industry as livestock manure contains valuable nutrients used by farmers.

Manure organics are regularly incorporated back into the land and it was vital that we developed a process that allowed for this practice to continue more effectively. This is why we developed a propriety, nutrient additive polymer blend called grō. Not only is it biodegradable, but it also offers many other agronomic benefits, including optimized crop development, and helping to eliminate soil erosion and surface runoff.

More and more farmers are turning to sustainable solutions to implement into their practice. How important is sustainability to your company?

Sustainability is at the core of everything we do. We are committed to advancing sustainable global food systems, in a safe, responsible and sustainable way.

Our approach to manure treatment embodies who we are as a company: a team of problem solvers who have come together to offer a positive and enduring impact to our customers, and their consumers.

Turning to sustainable technology has never been important, especially in times of uncertainty such as the ongoing COVID-19 and climate change. What are some of the common problems currently faced by livestock farmers and how does your technology help to tackle these problems?

While livestock producers face different problems depending on where they are located, it has been stated that there are three common challenges for livestock farmers: feed sourcing, manure processing, and climate change. Producing the abundant food supply that consumers have come to expect, has put a strain on the environment.

In response to the conscious consumer demand to move towards a low-carbon future, our solution re-imagines manure handling to create regenerative, restorative, and sustainable food production in such a way that it can also be more profitable for the producer!

How do you see the future of farming changing over the next 10 years?

The increasing global demand for food is going to require more precise agriculture practices, an acceleration in the consolidation of farms, increasingly limited water availability, and a focus on improving soil health will emphasize farm resource optimization.

We predict that we may even start seeing more farms grow feed crops in the desert, just as one of our clients is doing in Lebanon!

Image Credit: DFA (Dairy Farmers of America)

Do you believe that with better manure treatment technology, we can not only help the planet but help farmers financially too?

YES! We absolutely believe that sustainability and profitability are not mutually exclusive and that sustainable practices can, in fact, can lead to increased farm profitability.

What does the future look like for Livestock Water Recycling?

We are currently building out our distribution network beyond what we currently have in place in the UK, USA, Europe, and Russia. While we continue to expand into new geographic markets and industry sectors, our continued focus on digitizing manure will lead us to new innovations that will help producers decarbonize the food chain.

Where can readers find more information?

Visit: www.livestockwaterrecycling.com

Watch: https://www.youtube.com/watch?v=A_x5jSKBi4k

Follow: https://twitter.com/LWR_Inc

About Livestock Water Recycling

LWR creates value for food producers by reducing the expense and impact of waste liquids with a multi-patented, award-winning waste-to-worth approach to on-farm manure treatment.

Recently making the FoodTech 500, claiming the 31st spot, they are focused on digitizing manure to help producers decarbonize the food chain through informed decision making around fertilizer sales, nutrient trading, carbon credits, and the rapidly expanding biogas sector.

LWR is on a mission to increase farm profitability through sustainable manure treatment and ultimately envision lagoon-free food systems!