A group of researchers from the Nanyang Technological University, Singapore (NTU Singapore) recently created a plant-based emulsifier that is rich in antioxidants and protein and also has the properties to replace dairy or eggs in food staples like salad dressings, mayonnaise, and whipped cream.

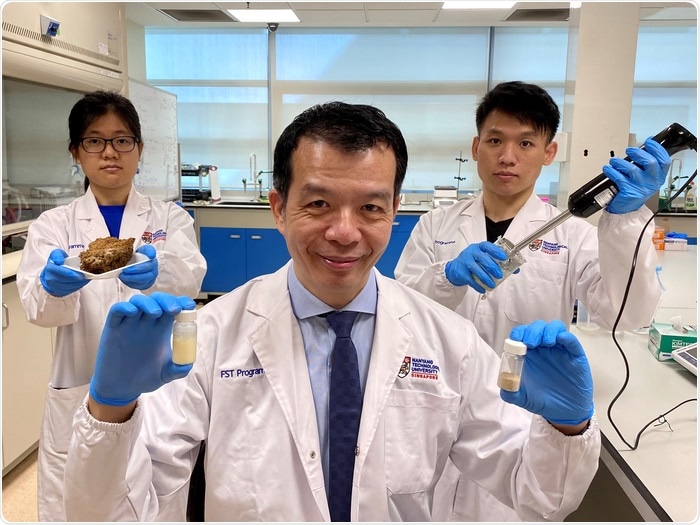

(L-R) NTU PhD student Ms Chin Yi Ling from the Food Science and Technology (FST) programme, FST programme director Professor William Chen, and Research Fellow Dr Josh Chai, also from FST. Image Credit: Nanyang Technological University, Singapore.

Emulsifiers are vital for food production, and they aid in stabilizing a combination of two liquids that do not mix easily, like water and oil. For instance, egg yolk is the commonly used emulsifying agent in mayonnaise to assure that the water and oil do not separate.

The NTU-developed emulsifier also helps in reducing food waste–as it is produced by fermenting brewers’ spent grain—a by-product of the beer-making industry. It is calculated that every year approximately 39 million tons of similar spent grains are discarded into landfills globally, where it decomposes and adds to greenhouse gas emissions.

The research, which portrays an innovation that helps reduce waste, reflects NTU’s commitment to alleviating the impacts on the environment—one of four of humanity’s grand challenges that the University attempts to resolve through its NTU 2025 strategic plan.

To develop the emulsifier, brewers’ spent grain was fermented—before further processes to extract the proteins—which, when dried, are immediately viable for manufacturing foods like mayonnaise.

The mayonnaise manufactured with the NTU-plant-based emulsifier had higher amounts of protein, and more amounts of certain essential amino acids, compared to store brand mayonnaise. The calorie and fat contents were the same compared to typical store brand mayonnaise, however, the NTU-made mayonnaise had more antioxidants and nutrients.

Mayonnaise prepared with the NTU plant-based emulsifier was also similar in taste to the store-bought mayonnaise. Laboratory tests carried out by the scientists also revealed that NTU-made mayonnaise revealed better texture and spreadability when compared to its off-the-shelf counterpart.

Our plant-based emulsifier is yet another triumph for NTU, as we look to find successful ways to find new uses for products that would otherwise be left to waste. Each year, approximately 39 million tons of brewers’ spent grain is generated globally by the brewing industry and is sent to landfills.”

William Chen, Professor and Director, Food Science and Technology Program, Nanyang Technological University

Professor Chen who led the project, stated, “Upcycling this as a potential human food source is an opportunity for enhancing processing efficiency in the food supply chain, as well as potentially promoting a healthier plant-based protein alternative to enrich diets.”

The NTU researchers behind the innovation also include Dr Josh Chai, Research Fellow at NTU’s FST program, and Ms Chin Yi Ling, a PhD student, also from FST.

The findings of the research were published in Food Chemistry: X, a peer-reviewed academic journal.

Using nature as a solution

NTU researchers state that at present, brewers’ spent grain is not commonly employed in food processing mainly due to the difficulty in protein extraction. The proteins are “trapped” inside their complex structure and hence the commercial processes used currently to release them like high temperature or chemicals are expensive and complicated.

Even though there are other uses for brewers’ spent grain, like solid fuel and cattle feed, the NTU-made emulsifier concentrates on its human nutritional aspect and uses natural solutions to enhance its value.

The NTU researchers identified that a simpler and cost-effective alternative to release the protein potential of brewers’ spent grain was to use a fungus—Rhizopus oligosporus—commonly seen and used in the production of tempeh, a fermented soybean food product common in Southeast Asia.

Upon fermentation of the mixture, the fungus produces enzymes that break down the complex molecular structure of the spent grain, making it an easy and inexpensive means of extracting the antioxidants and proteins within.

Our emulsifier is as an impactful solution to not only cut down on waste but potentially improve human diets by introducing a plant-based protein that is widely accessible. Furthermore, our emulsifier allows us to upcycle a would-be waste product.”

William Chen, Professor and Director, Food Science and Technology Program, Nanyang Technological University

“The environmental benefits of upcycling are immense, aside from minimizing the volume of discarded materials and waste being sent to landfills each year, it also reduces the need for production using new or raw materials which means a reduction in air pollution, water pollution, greenhouse gas emissions and often conservation of global resources,” added Professor Chen.

The NTU researchers further intend to optimize their protein extraction methods to enhance its quality and yield. The scientists also added that they would be experimenting with the emulsifier in various food products, like soybean milk and ice cream, before diversifying their emulsifier through partnerships with the food and beverage partners.

Owing to the spreadable properties of the emulsifier, the researchers anticipate investigating the cosmetic and pharmaceutical uses in products like lipsticks, topical creams, and more.

Source:

Journal reference:

Chin, Y. L. et al. (2022) Upcycling of brewers’ spent grains via solid-state fermentation for the production of protein hydrolysates with antioxidant and techno-functional properties. Food Chemistry: X. doi.org/10.1016/j.fochx.2021.100184.