The Future Sustainable Food Systems research group at the University of Helsinki, in collaboration with the VTT Technical Research Centre of Finland, found that fungus-produced ovalbumin can reduce the environmental impact of chicken egg white powder. This is particularly true when low-carbon energy sources are used in the production process.

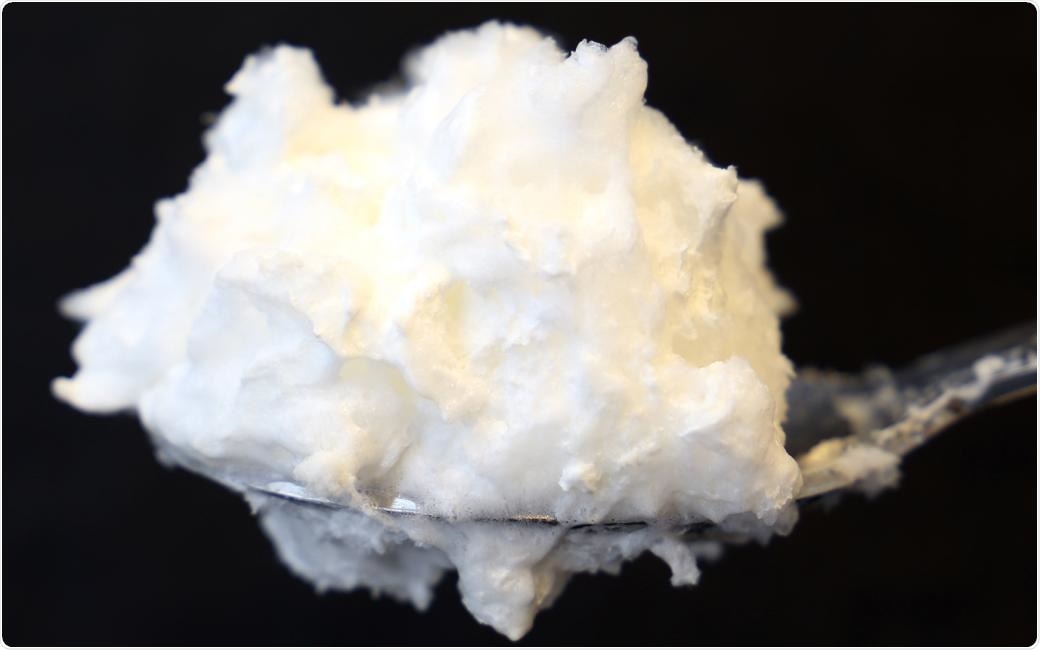

Egg white protein produced by precision fermentation has excellent foaming properties. Image Credit: VTT Technical Research Centre of Finland.

Due to the general high-quality protein content, chicken egg white powder is a commonly used component in the food sector. In 2020, the annual consumption of egg proteins was estimated to be over 1.6 million tons, with the industry projected to grow in the future years.

The rising demand raises concerns about both sustainability and ethical behavior. Parts of the egg white powder manufacturing chain, such as feeding chickens for egg production, contribute to a considerate amount of greenhouse gas emissions, water shortages, biodiversity loss, and deforestation. Further, rigorous chicken rearing has resulted in zoonotic disease epidemics by acting as a reservoir for human viruses.

The food sector is progressively interested in finding sustainable alternatives to animal-based proteins. When implemented for recombinant ingredient synthesis, cellular agriculture—a biotechnology-based method also known as precision fermentation—uses a microbial production system to decouple the production of animal proteins from animal farming and produce other specific proteins instead.

For example, more than half of the egg white powder protein content is ovalbumin. VTT has succeeded in producing ovalbumin with the help of the filamentous ascomycete fungus Trichoderma reesei.”

Dr Emilia Nordlund, VTT Technical Research Centre of Finland

Dr Emilia Nordlund adds, “The gene carrying the blueprints for ovalbumin is inserted by modern biotechnological tools into the fungus which then produces and secretes the same protein that chickens produce. The ovalbumin protein is then separated from the cells, concentrated, and dried to create a final functional product.”

Generally, cell-cultured products require high electricity than usual agricultural products. Thus, the type of energy source employed has an influence on the amount of environmental impact. Moreover, the quantity of agricultural inputs required for producing ovalbumin by microbes—for example, glucose—is often much smaller per kilogram of protein powder.

According to our research, this means that the fungus-produced ovalbumin reduced land use requirements by almost 90% and greenhouse gases by 31–55% compared to the production of its chicken-based counterpart. In the future, when production is based on low carbon energy, precision fermentation has the potential to reduce the impact even by up to 72%.”

Natasha Järviö, Doctoral Researcher, University of Helsinki

The results for the environmental effect of water consumption were less conclusive, indicating a high degree of dependence on the projected location of the ovalbumin production facility. In conclusion, the study reveals that precision fermentation technology has the potential to improve protein production sustainability, which may be further enhanced by the use of low-carbon energy sources.

Source:

Journal reference:

Järviö, N., et al. (2021) Ovalbumin production using Trichoderma reesei culture and low-carbon energy could mitigate the environmental impacts of chicken-egg-derived ovalbumin. Nature Food. doi.org/10.1038/s43016-021-00418-2.