Specialists in innovative porous plastics technologies – Porvair Sciences has introduced a new range of Vyon® PTFE porous plastic materials for applications where temperature or chemical resistance is important.

Image Credit: Porvair Sciences

Vyon® PTFE is a unique, high-performance porous plastic material manufactured from 100% pure polytetrafluoroethylene. Through sintering, Porvair produce porous PTFE structures composed of tortuous interconnected pathways with minimal dead-end pores. Combining the unique porous structure and tight pore distribution, Vyon® PTFE offers enhanced controlled flow of liquids and gases making it ideal for filtration, separation, and retention of biological and chemical materials.

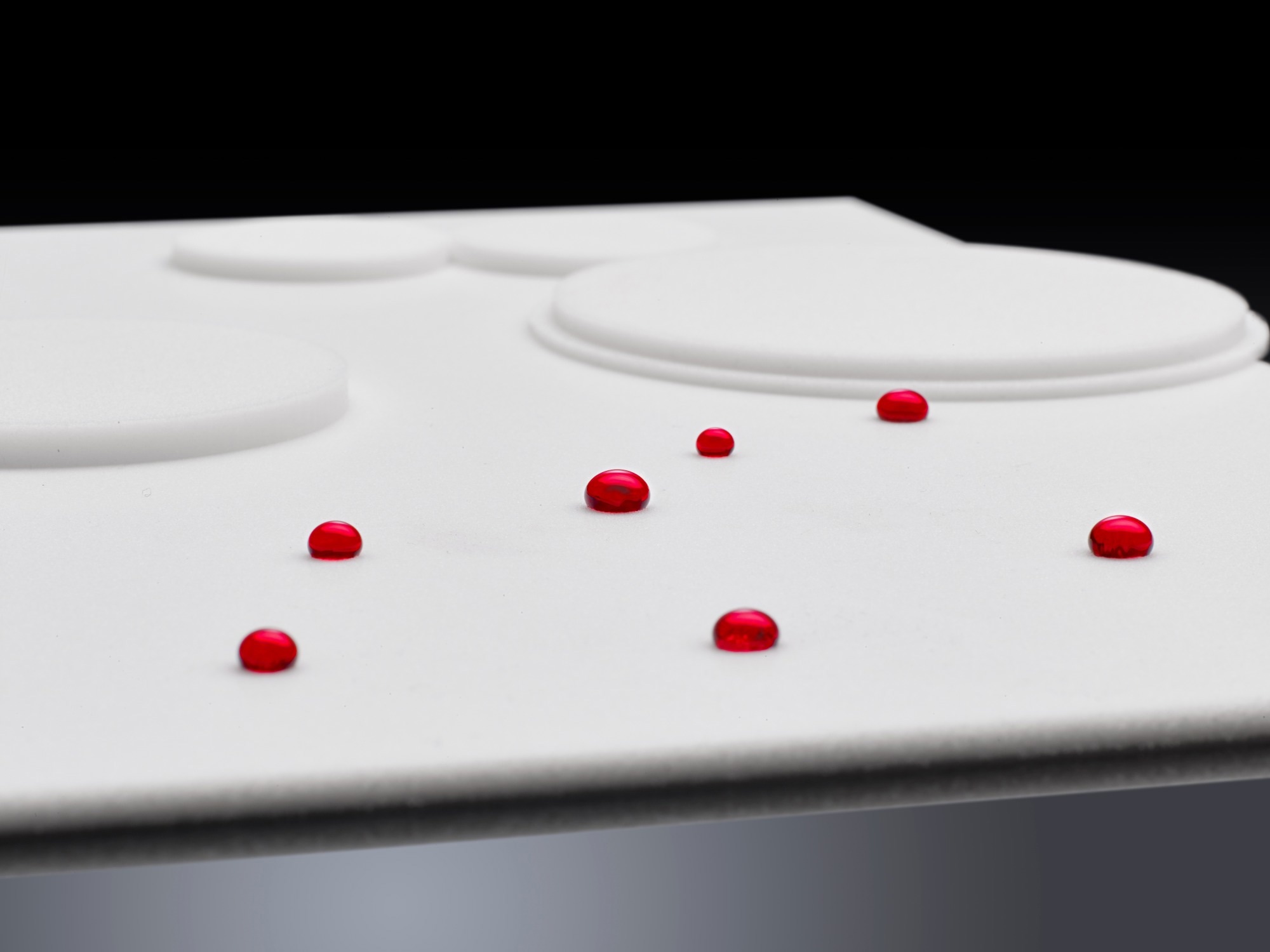

Developed to cope with the most demanding applications, Vyon® PTFE is extremely durable offering superior chemical resistance to most aggressive media and corrosive solvents. In addition, Vyon® PTFE components are temperature resistant up to 260 °C, naturally hydrophobic, exhibit minimal flex fatigue and contaminants do not easily adhere to components made from this advanced engineering plastic.

Sheets of advanced Vyon® PTFE plastic materials can be manufactured into a variety of shapes and sizes to suit your specific application. Tightly controlled manufacturing processes ensure that Vyon® PTFE porous plastic components for your product are produced with consistent, reproducible, and controlled critical properties such as thickness, diameter, and porosity.

Vyon PFTE is a naturally hydrophobic porous plastic that is ideal for applications such as chromatographic separations where longer term solvent impermeability (e.g., acetonitrile can be held up for 24hrs) is important.

For further information about Vyon® PTFE please visit https://www.vyonporousplastics.com/draft/vyon-polytetrafluoroethylene-ptfe/