The world will need to produce double the amount of food by 2050 to feed the rapidly growing population, and 3D printing could provide the solution. Researchers from the University of Ottawa have outlined a range of factors that feed into the quality of food produced by additive manufacturing.

Image Credit: Arthimedes/Shutterstock.com

In a paper published in the journal Physics of Fluids this month, researchers Ezgi Pulatsu and Chibuike Udenigwe highlight the potential of using 3D printing to mass produce food for human consumption, although several challenges must first be overcome before 3D printing can cause any disruption in the food industry.

Feeding the 10 billion

By 2050, it is predicted that the world’s population will have swelled to just under 10 billion. This means that the world’s already stretched resources will have to go even further to produce double the amount of food (compared with 2009 food production).

The world faces a looming food crisis, where the growing population alongside climate change is putting increasing pressure on our food systems to produce enough food. Recent figures have revealed that one in ten people go hungry each day. In addition, a huge 3.1 billion cannot afford a healthy and nutritious diet. There is an urgent need for solutions that will allow us to produce enough food for our growing population to ensure that we can feed not only the additional people on the planet but also eradicate hunger.

Printing our food

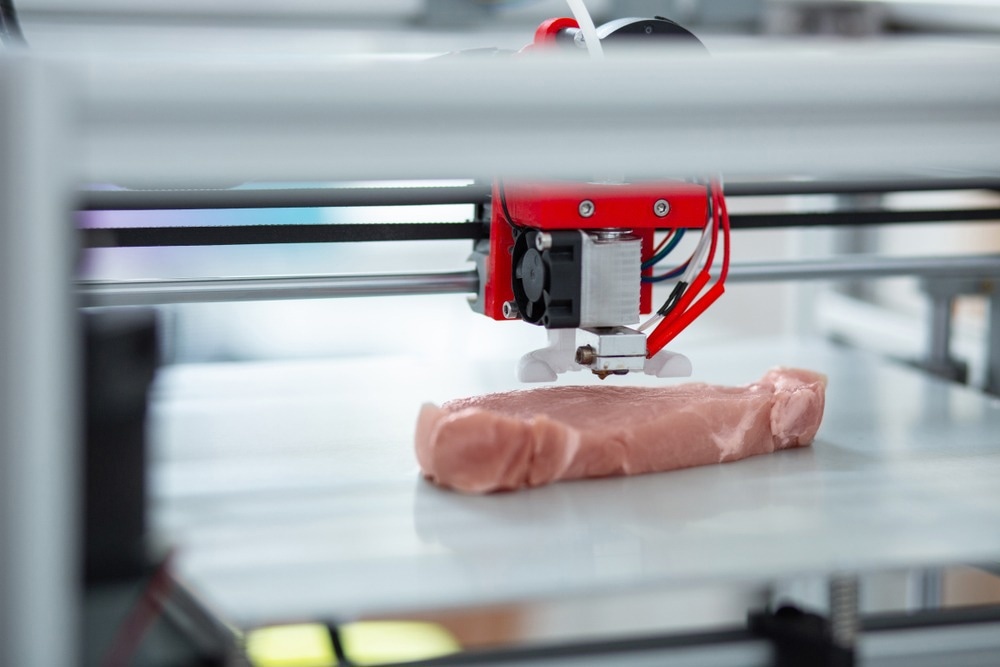

3D printing has already made waves in the food industry. Innovators have used the technology to produce a wide array of food types. Italian pasta producer Barilla, for example, collaborated with Dutch company TNO in 2016 to create the first 3D printer for fresh pasta. Redefine Meat, a meat alternative producer, has been working on using the 3D printing process to create ‘meat’ from vegetarian sources that mimics the texture of real meat, something that has so far alluded to the alternative meat market.

While these developments have been innovative and showcased the potential capabilities of 3D printing in the food industry, the 3D printing process has yet to be refined for the mass production of food items - such mass production that could help address the needs of the looming food crisis.

Now, researchers at the University of Ottawa have gotten us one step closer to establishing 3D printing systems capable of handling the increasing demand for quality food. Researchers Pulatsu and Udeniqwe have identified a wide range of factors that impact the quality and shape complexity of food produced by 3D printers. By considering these factors, food producers can develop their 3D printing processes so that the quality of the food and speed of production can be improved.

To create food via 3D printing, food shapes and their geometric codes must be designed, and the substances used to print must be pre-processed. Food ‘ink’ is then printed in predetermined shapes, layer upon layer, to create the physical form of the food, which is then post-processed to create an edible end product. Each of these individual steps (design, pre-processing, manufacture, post-processing) presents an opportunity for innovation. The food’s texture, for example, can be altered by amending the printing patterns that determine its microstructure.

The researchers in Ottawa highlight how control is vital in the manufacturing process, that the flow of ‘ink’ must be stopped once deposited to retain the intended shape. They also recognize that post-processing actions should not destroy the textures and tastes created in early steps. They also suggest that establishing a series of computer-controlled movements, known as a printing path, is important to improving the efficiency of food production by giving more refinement and control to the process.

Image Credit: Dmytro Zinkevych/Shutterstock.com

Future studies are needed before 3D-printed food reaches its full potential

According to Pulatsu, future studies are needed to investigate the cost efficiency of different technologies to better understand how 3D printing technology can move forward in food manufacturing. A collaborative approach that draws together the expertise of chefs, engineers, and food scientists will be vital to establishing 3D printing as a reliable food production method.