Printing living cells into functional tissues is a highly complex process, and with each technological advancement, new challenges emerge. The Levato lab at UMC Utrecht has successfully combined two promising printing processes to boost cell density, cell survival, and specialization in bioprints. The solution: granular biogels or resins.

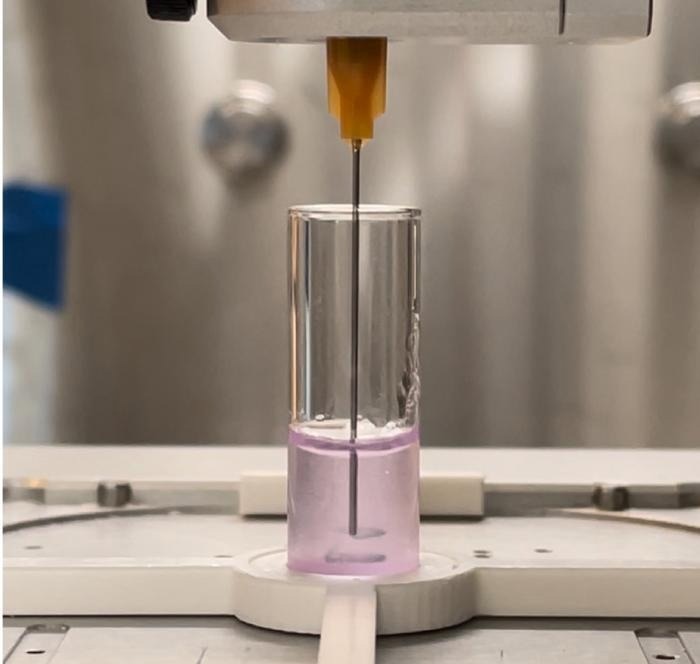

Extrusion bioprinting within a granulated gel. Image credit: LevatoLab, UMC Utrecht,

Extrusion bioprinting within a granulated gel. Image credit: LevatoLab, UMC Utrecht,

Cells are High-Maintenance

Bioprinting, or printing living cells, is a potential technology for creating functional tissues from stem cells. However, combining this sophisticated technology with sensitive cells poses a significant problem. Cells must be treated to survive and grow in the finished product if researchers want to bioprint them. To form a functional tissue, they must be able to grow, move, and communicate with one another.

Various printing strategies have been tried to overcome this, each with its own set of advantages and disadvantages. Cells can be deposited in a variety of types and large numbers in 3D extrusion printing; however, the procedure is time-consuming, causes mechanical stress to the cells, and is gravity-dependent, all of which are detrimental to the cells’ survival and functioning.

The challenge with quick volumetric bioprinting is that cells are scattered randomly in the resin and lesser quantities, and because the final print comprises solid resin, the cells are unable to function and communicate efficiently.

Creating a Granular Microworld

To address this challenge, bioprinting materials must provide an environment that is conducive to cell self-organization and communication. While this is often possible with soft hydrogels, maintaining good printing resolution and shape fidelity of these materials remains a major challenge, particularly when employing traditional layer-by-layer fabrication techniques.

Davide Ribezzi, the first author, investigated the use of granular resins to address these issues.

Granular gels are basically gel microparticles packed tightly together. While each microparticle possesses comparable properties to its bulk hydrogel counterpart, packed microgel particles can be designed and customized to display a broad array of added useful properties.

Davide Ribezzi, Study First Author, University Medical Center Utrecht

Particulate biomaterials are thus a possible solution for overcoming issues with bulk cell encapsulation and material processability in printing techniques.

Combining Different Printing Strategies

The researchers were able to combine extrusion and volumetric printing thanks to the granulated resins. Extrusion printing allows specific cells or other chemicals to be deposited in the resin. This method optimizes the balance between the speed of volumetric printing and the precision of extrusion printing.

Because the gel travels around the printing nozzle like custard around an intrusive finger, the cells can be deposited in numerous layers rapidly without worrying about the structure’s strength. The procedure can then be completed by volumetric printing by constructing and finessing the shapes around the extruded cells.

This procedure was not without complications.

Processing biological materials always requires lots of attention and meticulous planning of the experiments. But in our research we exploit the thermal properties of the microgel, which allows for a precise tuning of the mechanical and optical properties. This translated into tunable stimuli sensed by the embedded cells. However, this higher degree of tuning needed an even higher degree of attention and precision during the printing process.

Davide Ribezzi, Study First Author, University Medical Center Utrecht

More Biological Activity; the Proof is in the Granular Pudding

Experiments with cells show that granulated resins allow for significantly more biological activity following printing, far outperforming solid gels. Within eight days of being printed in resin, stem cells were able to spread out more, epithelial cells made more junctions, and neuron-like cells created more connections.

For future studies, we envision the mixing and even local patterning of microgels obtained from different materials. It would allow us to create composite constructs with unique properties, or with bioactive pockets releasing for example drugs. These tools will boost tissue functionality, open up additional opportunities for tissue engineering, regenerative medicine, and the emerging area of engineered living materials.

Davide Ribezzi, Study First Author, University Medical Center Utrecht

Source:

Journal reference:

Ribezzi, D., et al. (2023). Shaping Synthetic Multicellular and Complex Multimaterial Tissues via Embedded Extrusion‐Volumetric Printing of Microgels. Advanced Materials. doi.org/10.1002/adma.202301673.