Ice is used in a novel 3D printing technique to create a template for synthetic blood vessels in tissue that has been engineered.

3D Ice Printing can Create Artificial Blood Vessels in Engineered Tissue. Image Credit: Feimo Yang, Carnegie Mellon University

3D Ice Printing can Create Artificial Blood Vessels in Engineered Tissue. Image Credit: Feimo Yang, Carnegie Mellon University

The vessels may eventually be employed in medication testing or artificial organ transplants, according to researchers.

Currently, over 100,000 individuals in the United States are in need of organ transplants. However, the demand for organs, such as hearts, kidneys, and livers, far exceeds the available supply.

Consequently, many individuals are forced to endure lengthy waiting periods, sometimes spanning years, before a suitable donor organ becomes available. Tragically, approximately 6,000 Americans lose their lives each year while awaiting transplantation.

Tissue engineering aims to address the disparity between the demand for transplants and the availability of organs by cultivating organs and tissues in laboratory settings. One significant hurdle in this field is the establishment of blood vessel networks within artificial organs that mimic the functionality of natural ones, ranging from intricate capillaries to larger arteries.

Conventional designs for artificial blood vessels often fail to replicate the complex structure found in the body's natural vascular system.

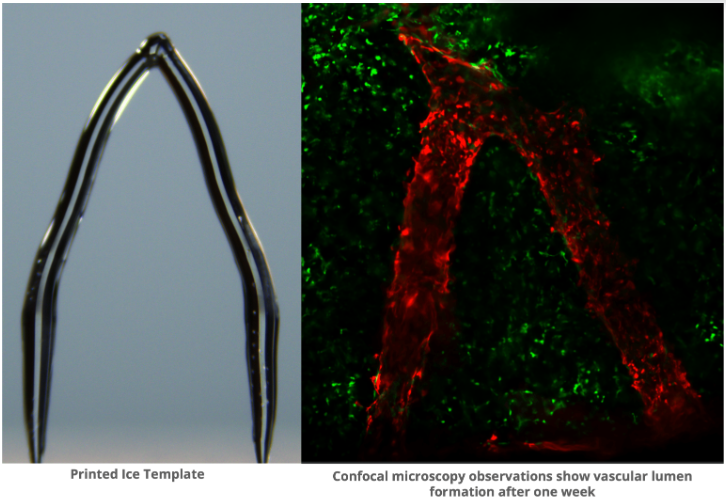

New research proposes that human blood vessel-like structures can be generated using 3D ice printing. Feimo Yang, a Graduate Student conducting research in the laboratories of Burak Ozdoganlar and Philip LeDuc at Carnegie Mellon University, will unveil their findings at the 68th Biophysical Society Annual Meeting in Philadelphia, Pennsylvania.

3D ice printing generally involves adding a stream of water to a very cold surface.

What makes our method different from other kinds of 3D printing is that instead of letting the water completely freeze while we’re printing, we let it maintain a liquid phase on top. This continuous process, which is what we call freeform, helps us to get a very smooth structure. We don’t have a layering effect typical with many 3D printing.”

Feimo Yang, Graduate Student, Laboratories of Burak Ozdoganlar and Philip LeDuc, Carnegie Mellon University

Furthermore, they utilized heavy water, distinguished by a higher freezing point and a smoother structure resulting from the replacement of hydrogen atoms with deuterium atoms.

After that, these 3D-printed ice templates are embedded in GelMA, a gelatinous substance. Realistic blood vessel channels are left behind when the ice melts and the gelatin hardens in response to UV light.

The scientists were able to show that they could grow endothelial cells successfully - the same cells found in blood vessels - into the artificial blood vessels. For up to two weeks, the cells were able to survive on the gelatin. (They plan to culture those cells for an extended period of time in the future.)

Yang highlights that 3D printed blood vessels hold potential for drug testing on blood vessels and could also find applications in organ transplantation. Moreover, prior to administering drug treatments to patients, these vessels could be coated with the patient's own cells to observe their reaction to the treatment.

This new method has the potential to greatly advance the development of intricate, realistic blood vessel networks for use in tissue engineering.