Overview

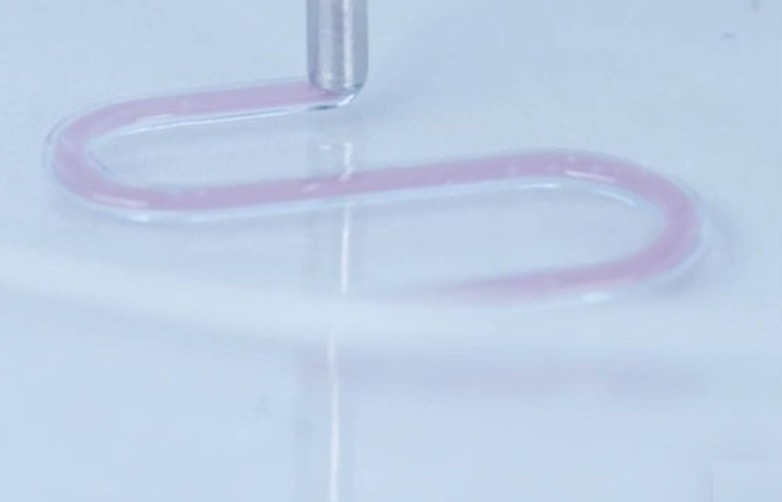

Extrusion-based bioprinting is based on CNC machining processes, precisely dispensing biocompatible materials layer by layer while following tool paths created in slices from 3D models. The extrusion-based 3D bioprinters are made to be flexible, allowing bioengineers to work with a wider variety of biomaterials and enabling more applicable tissue engineering.

The bioprinters of CELLINK are given below.

BIO X™

- Academics, researchers, and innovators frequently use this award-winning design as their preferred bioprinter.

Image Credit: CELLINK

BIO X6™

- This is yet another award-winning design that offers six printheads for unmatched bioprinting flexibility.

Image Credit: CELLINK

INKREDIBLE+™

- The first bioprinter produced by CELLINK completely transformed the sector, and the company is still working hard to advance training and education.

Image Credit: CELLINK

Applications

Light-based 3D bioprinting

- Light-based bioprinting, an adaptation of stereolithography (SLA) techniques, creates constructs by starting chemical reactions that solidify or cure bioinks only where they have been illuminated.

- They typically cure entire layers simultaneously with a variety of light-based technologies, such as digital light processing (DLP), and are therefore much faster. Light-based bioprinters are also able to reproduce more intricate details at much higher resolutions because of the millions of small points of light that make up their structures.

Lumen X+™

Image Credit: CELLINK

- With speed, accuracy, and fidelity, the DLP bioprinter can produce microscopic features.

BIONOVA X

Image Credit: CELLINK

- High-resolution, high-throughput 3D bioprinting is made possible by this DLP bioprinter.

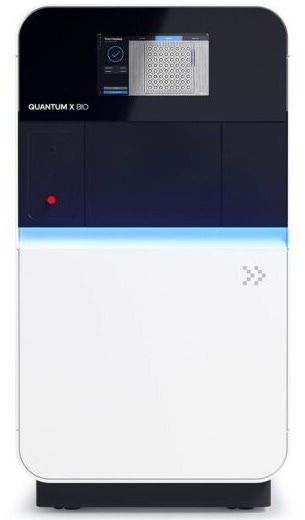

Quantum X bio

Image Credit: CELLINK

- The bioprinter is equipped with every feature required for printing with bioresins made of living cells.

Biodispensing

Bio CELLX

Image Credit: CELLINK

- This fully automated biodispensing system uses 3D cell biology to power the benchtop.

Key features

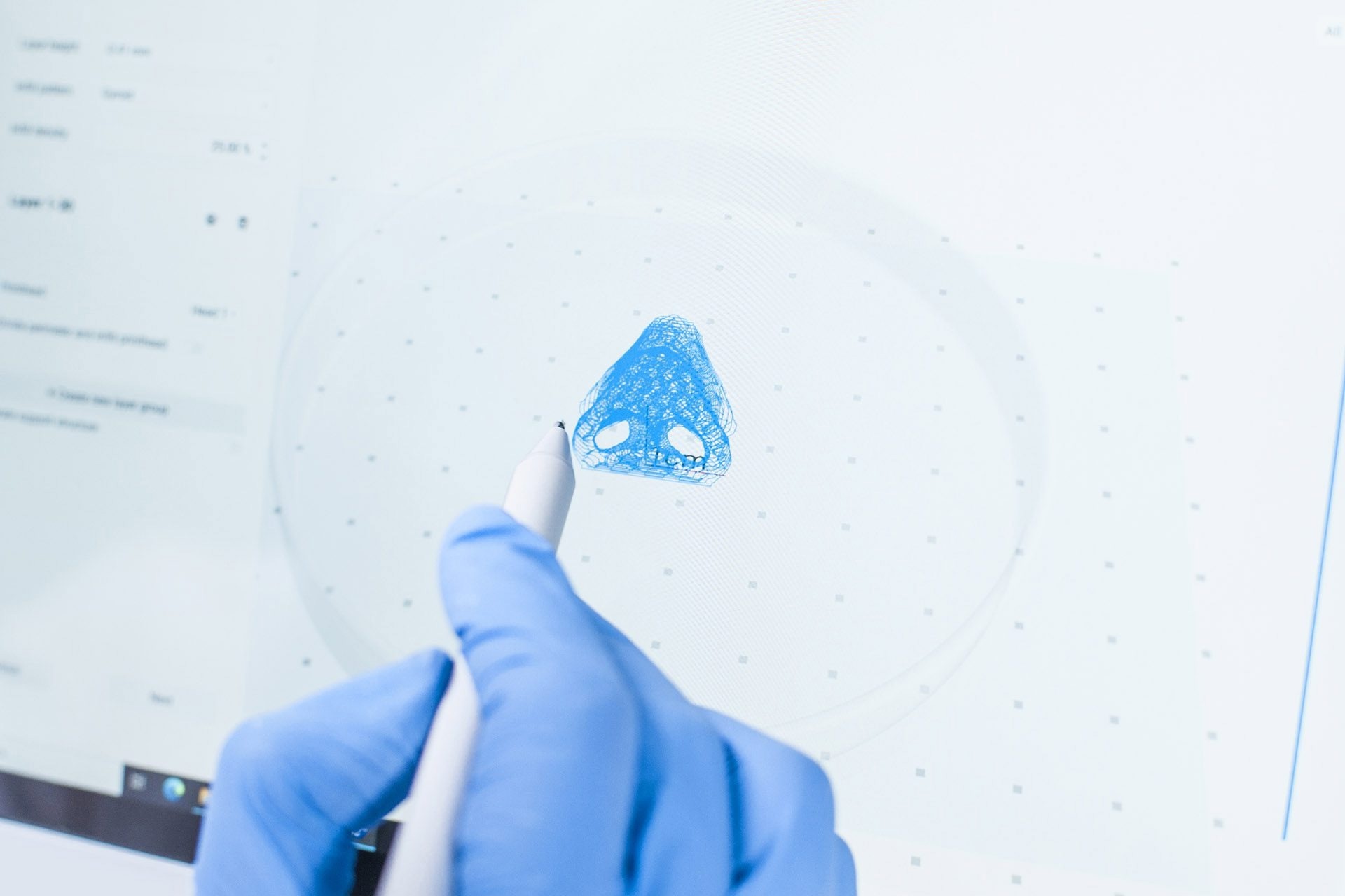

Bioprinting will alter how medicine is practiced in the future because the future is created in the present.

Image Credit: CELLINK

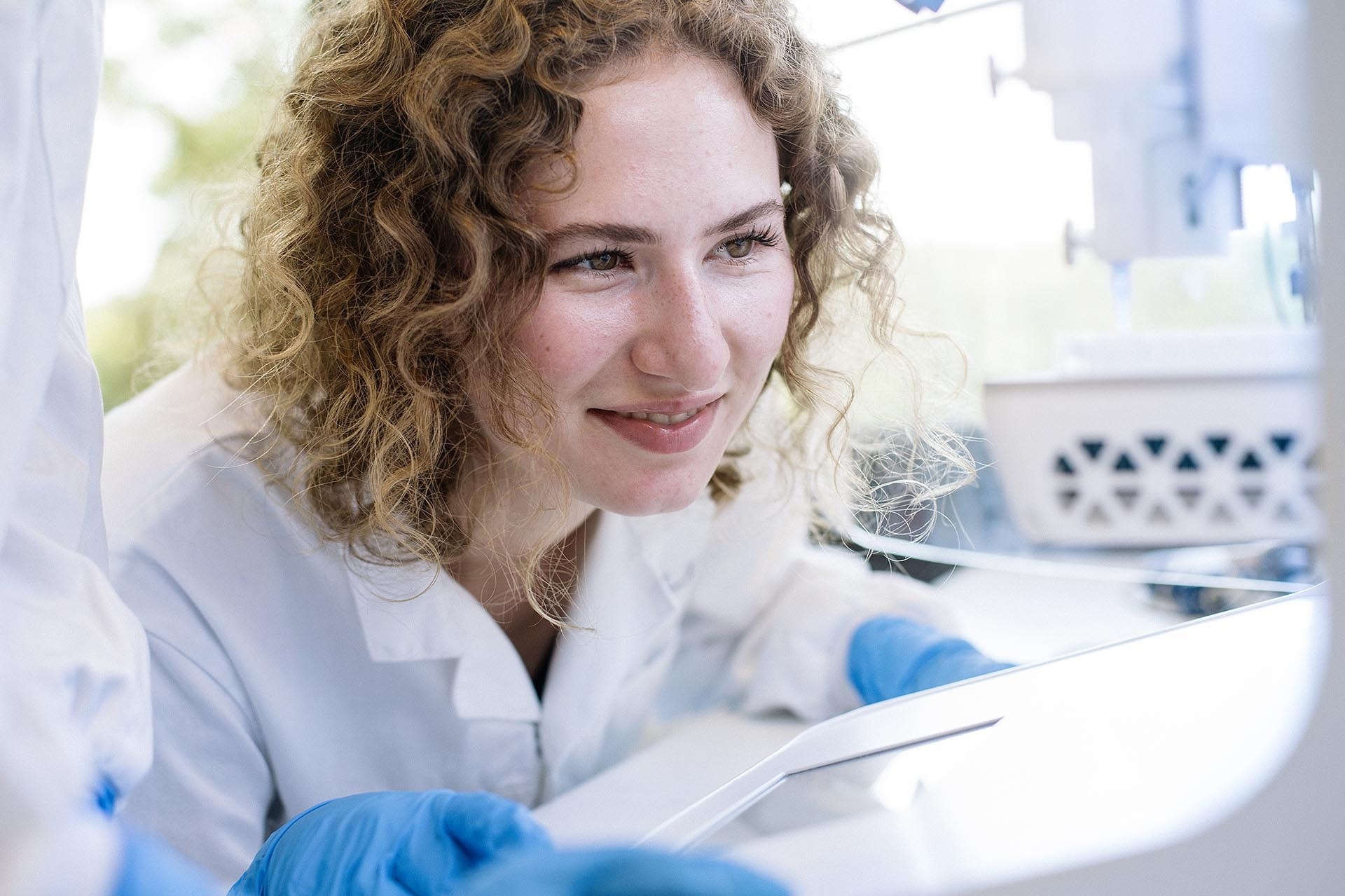

Delivering high-quality products and keeping the work cutting edge

Image Credit: CELLINK

- Modern technology is being installed in thousands of laboratories around the world, enabling ground-breaking scientific discoveries. 3D bioprinters and bioinks have made revolutionary strides in academic and clinical medicine, thanks to the unparalleled dedication to quality and innovation.

Complete in-house product development and manufacturing

A high-quality team creates high-quality, innovative bioprinters

- The in-house development of bioprinters, bioinks, and software is made possible by the technical team, which includes mechanical, electronics, robotics, and software engineers, as well as UX/UI designers, biomaterial scientists, and tissue engineers. The development process involves close collaboration between the development and manufacturing teams.

- This has made it possible for the company to move more quickly from prototype to first batch and then to series production, all while maintaining compliance with the ISO 9001 Quality Management System.

- Working in accordance with ISO 9001 ensures that the customers receive dependable goods and services. When delivering new and inventive products and solutions to the customers, this really gives total control since the team’s full power, knowledge, and enthusiasm can be put to work.

- The ability to develop products with a clear need in the bioprinting and life sciences industry has been made possible by having a full in-house development team that collaborates and partners closely with users of the technology.

Image Credit: CELLINK

- The entire production is carried out in-house to maintain high standards.

CELLINK's Production Team

Video Credit: CELLINK