Overview

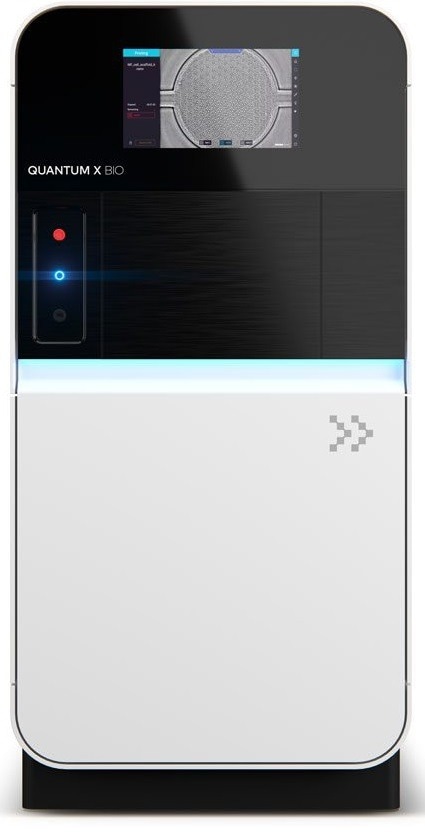

The 3D microfabrication from CELLINK is dedicated for biomedical and biological applications.

Applications

2PP bioprinting – creating the world’s most accurate 3D bioprinter

Biologist’s lens is of great help for reimagining Nanoscribe’s Two-Photon Polymerization (2PP) printing technology. It is time to examine bioprinting on the nano- and microscale with the help of Quantum X Bio.

Optimized for cellular work

A temperature-controlled environment collectively with onboard sterility measures makes Quantum X Bio the ideal choice of system for examining biological applications.

Intuitive software

With the availability of easy-to-use software solutions and a library of tested bioprinting STL models, Quantum X Bio contracts for an intuitive and direct setup.

Smart, connected workflows

Users can guarantee the quality of their print job right from start to finish via sensors and video data. Also, time can be saved by controlling the system from the desktop software or the touchscreen.

Flexibility prioritized

Users can print any 3D design in a virtual manner with unparalleled accuracy and speed on an extensive range of substrates—such as Petri dishes and microscope slides.

Unprecedented accuracy

It is possible to unfasten high-performance 3D bioprinting along with feature resolution down to 100 nm on areas up to 25 cm².

Extensive biomaterial offerings

Users can select between the customized, functionalized biomaterials developed at Nanoscribe, CELLINK, and Advanced BioMatrix, or from photoresins that are externally available.

Video Credit: CELLINK

Be prepared for live-cell printing

Quantum X Bio offers all the features required by the users for printing along with bioresins consisting of living cells—and keeping them alive. This enables users to use exciting new applications like smart/living materials, vascularized tissue printing, sub-micron patterning, and topology for cell mechanics and migrations.

- Open system consistent with any bioresin that is available

- Barren and temperature-controlled surrounding

- Cell-friendly wavelength (780 nm)

- Cell viability >90% can be made possible

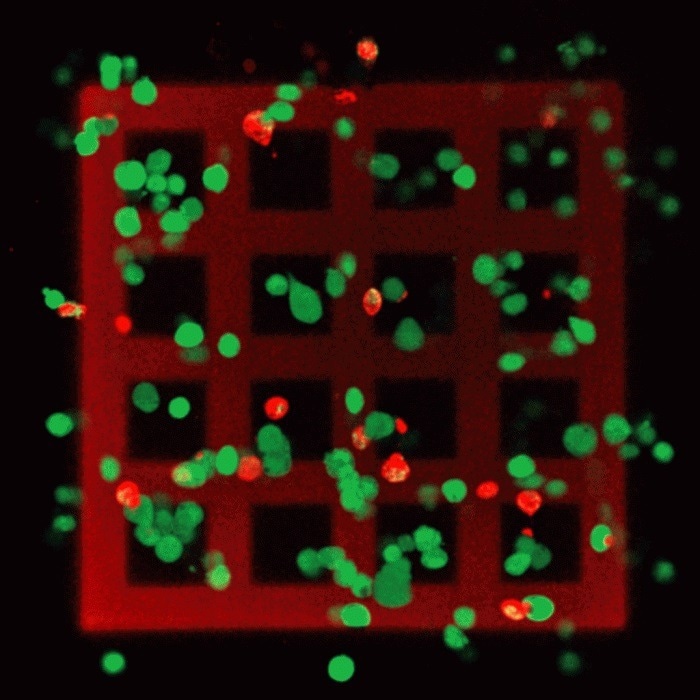

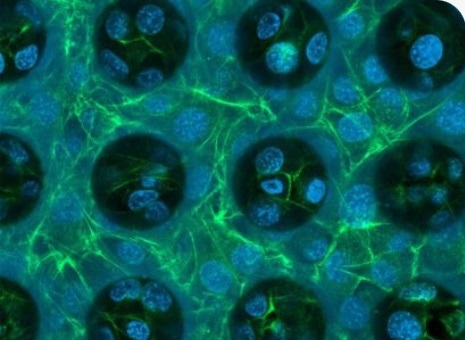

3D structure containing living NIH 3T3 fibroblast cells, printed from a custom bioink based on Gelatin methacrylate. Cell viability one hour after printing is >90% as obtained by live-dead staining. Image Credit: CELLINK

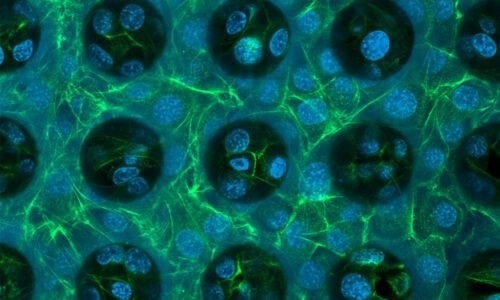

3D cell culture

It is possible for users to cultivate cells in 3D-printed microwell arrays. Due to the use of biocompatible materials, the cells have the potential to fix and proliferate as shown in the fluorescent microscope image.

Image Credit: CELLINK

Vasculature fabrication

By 3D bioprinting complicated microfluidic structures, vasculature models have the potential to be fabricated in an effective manner. In this context, the several circuits can be seen by flushing every structure with various colored fluids

Image Credit: CELLINK

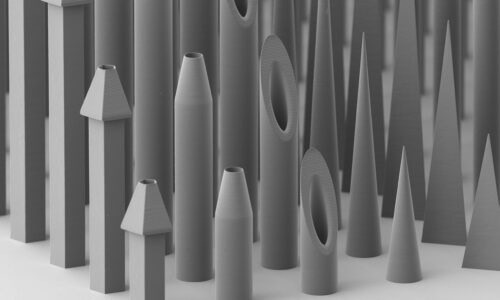

Drug delivery

As a result of the accurate microfabrication technology, Quantum X Bio allows 3D-printed drug delivery applications. The image illustrates the potential of the technology to identify a high aspect ratio.

Image Credit: CELLINK

Technical features

- Quick prototyping along with high accuracy, design freedom, and a direct workflow

- Cell-friendly wavelength (780 nm)

- Temperature-stable print chamber setting with substrate temperature control

- Custom materials usable

- Extensive range of universal and application-specific printing can be performed

- Industry-proven platform available for several substrate types

- Nano Clean Chamber Technology, guarantees sterility

Image Credit: CELLINK

What is 2PP bioprinting?

2-photon polymerization (2PP) needs two photons to provide the energy that has been essential to produce a photoreaction. Also, this only happens when two photons tend to overlap in the same time and space (X, Y, and Z).

The 2PP method enables users to print into the photoresist, allowing complicated constructs to be printed without extra support. Besides, since two photons are needed to activate the photoreaction, the smallest feature size has been limited to the volume where the two photons overlap, allowing submicron precision for the features!

Ready. set. print.

Users can organize and track their research projects with the help of intuitive software and outstanding data tracking. Also, they can generate, upload, print, and track their print job instantly from the touchscreen of the device or remotely from their PC.

With the availability of Nanoscribe’s UX-optimized software solutions, inspired by a bioprinting library of proven STL models, and tracking of sensor and video data at the time of printing, it is genuinely simple to obtain printing success.

Image Credit: CELLINK

Bioconvergence at its best

Having powered by NANOSCRIBE’s proprietary Two-Photon Grayscale Lithography (2GL®) technology and CELLINK’s award-winning cell-friendly technologies, Quantum X Bio high-accuracy 3D microfabrication bioprinter is the top of the class. 2GL has been tailored and reimagined keeping the tissue engineer and cell biologist in mind.

Microfabrication speed and accuracy fulfill patented Clean Chamber sterilization, advanced temperature controls, and biocompatibility to make the most rapid and accurate tool on the market for vasculature printing with outstanding shape accuracy.

Quantum X Bio promises to accelerate innovation across vital applications like cell biology, tissue engineering, and regenerative medicine.

Image Credit: CELLINK

Benchmark scores

Source: CELLINK

| . |

. |

| Surface roughness |

down to ≤ nm |

| Minimum feature size¹ |

down to 100 nm |

| Shape accuracy |

down to ≤ 200 nm |

| Batch processing |

up to 200 typical mesoscale structures over night |

| Autofocus precision |

down to ≤ 30 nm |

| Print field diameter |

25 mm divided by lens magnification |

| Maximum scan speed ² |

6.25 m/s divided by lens magnification |

Image Credit: CELLINK

General system properties

Source: CELLINK

| . |

. |

| Printing technology |

- Layer-by-layer 3D printing based on Two-Photon Polymerization (2PP)

- Two-Photon Grayscale Lithography (2GL®) with voxel tuning capability

|

| Substrates |

- Microscope slides (3 x 1” / 76 x 26 mm)

- Wafers 1” (25.4 mm) to 6” (150 mm)

- Glass, silicon, and further transparent and opaque materials

- Petri Dishes (35 or 50 mm)

|

| Photoresins |

- Advanced BioMatrix Hydrogels

- Xpect-inx Bioinks

- Nanoscribe IP-Photoresins (polymers)

- Nanoscribe GP Photoresin (glass)

- Customer User Materials

|

| Maximum printing area |

50 x 50 mm² |

Given values may vary depending on the photoresin and structure geometry

¹ 100 nm feature size control in all spatial directions

² e.g. for 10x magnification: 625 mm/s