Overview

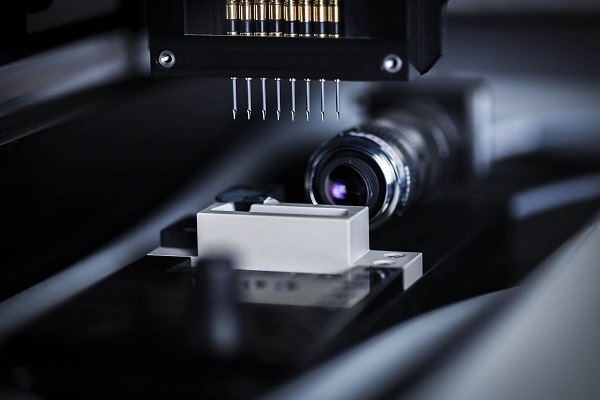

The sciFLEXARRAYER S12 from Scienion has been a completely automated non-contact dispensing system developed for ultra-low volumes.

The availability of a small all-in-one design and sliding door to reduce particle turbulences and contamination is the main benefit of the sciFLEXARRAYER S12, a completely automated non-contact dispensing system available for ultra-low volumes.

The sciFLEXARRAYER S12 has been developed and improved for medium-scale batch production, particularly for precise 12″ wafer loading.

With the help of the optimal dispensing area available for medium batch production, the sciFLEXARRAYER S12 system is available with a similar proprietary sciDROP PICO dispensing technology. Also, it is constructed to very high-quality standards as the bigger production units which can be done with heavy-duty design and low maintenance components.

Features

Compact

Availability of an all-in-one design

Sliding door

Contamination and turbulences have been decreased

Optimized

Available medium-scale batch production

Compact all-in-one design for manufacturing needs

The S12 is the ideal tool for constant and highly reproducible batch production, with a capacity ranging up to 12 microplates.

Compact all-in-one design for medium batch production

Image Credit: Scienio

Specifications

Source: Scienion

| . |

. |

| Dispense Volume |

30 – 800 pL/drop |

| No. of Dispense Capillaries |

From 1 to 8 PDC channels |

| Distance Dispense Capillaries |

4.5 or 9 mm increments |

| Target Holder |

380 x 380 mm |

| Capacity |

Up to 12 MTPs or 70 standard glass slides |

| Axis system |

X-Y linear magnetic & Z spindle drives |

| Resolution (step size) |

1 µm |

| Precision |

< 3 µm |

| Accuracy |

< 5 µm |

| Options |

Spot-on-the-fly, 3D drop camera, vacuum target holder, online target alignment, online array QC software |

| Dimensions (L,W,H) with enclosure |

1300 x 850 x 1200 mm |

| Weight |

420 kg |