A new synthetic biology study sponsored by the U.S. Army exploited micro-compartments in cells, prospectively allowing advances in bio-manufacturing for applications such as engineering, medicine, and protective equipment.

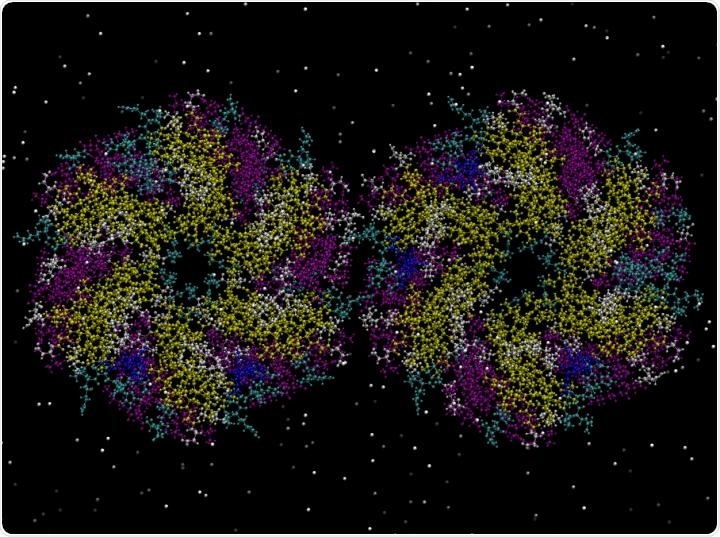

New Army-funded synthetic biologic research manipulates micro-compartments in cells, potentially enabling bio-manufacturing advances for medicine, protective equipment, and engineering applications. Image Credit: Monica Olvera de la Cruz, Northwestern University.

Because of their ability to sequester toxins into small compartments, bad bacteria can live in incredibly hostile conditions, such as the deeply acidic human stomach.

Northwestern University researchers regulated protein assembly and developed these micro-compartments into various sizes and shapes, like long polyhedrons and tubes, as part of a recent study published in ACS Central Science.

Since this research sheds light on how biological units, like organelles and viruses, evolve, it has the potential to help develop new approaches for developing synthetic cells, medicine, and nano-reactors that are crucial for nanotechnology.

These results are an exciting step forward in our ability to design complex protein-based compartments. Being able to control the size and shape of these compartments could enable sophisticated bio-manufacturing schemes that are customized to support efficient production of complex molecules and multi-functional materials that could provide the future Army with enhanced uniforms, protective equipment and environmental sensors.”

Dr Stephanie McElhinny, Program Manager, U.S. Army Combat Capabilities Development Command (DEVCOM), Army Research Laboratory

These findings could eventually result in new antibiotics that kill pathogen micro-compartments while sparing beneficial bacteria.

Researchers regulate protein assembly and form cell micro-compartments into various sizes and shapes, which could contribute to bio-inspired building blocks for a variety of engineering purposes.

By carefully designing proteins to have specific mutations, we were able to control assembly of the proteins that form bacterial micro-compartments. We used this also to predict other possible formations that have not yet been observed in nature.”

Dr Monica Olvera de la Cruz, Professor, Materials Science and Engineering and Chemistry, Northwestern University

Olvera de la Cruz was also in charge of the theoretical computation involved in this study. Several cells use compartmentalization to guarantee that many biochemical reactions can take place at the same time without intervening with one another. These protein-based micro-compartments are important for the survival of a broad range of bacterial organisms.

Based on previous observations, we have known that the geometry of micro-compartments can be altered. But our work provides the first clues into how to alter them to achieve specific shapes and sizes.”

Dr Danielle Tullman-Ercek, Associate Professor, Chemical and Biological Engineering, Northwestern University

Tullman-Ercek was in charge of the experimental part of the study. The Northwestern group used Salmonella enterica to investigate these critical compartments because these bacteria depend on micro-compartments to break down waste products from good bacteria in the gut. The micro-compartments were found to create long tubes when the researchers genetically engineered a protein derived from Salmonella.

“We saw these weird, extended structures. It looked like they used the varying building blocks to form different shapes with different properties,” said Tullman-Ercek.

Olvera de la Cruz and her colleagues used theoretical computation to estimate how different mutations resulted in different sizes and shapes. For this, they combined the mechanical properties of the compartment with the chemicals within the compartment.

Long tubes were formed as six-sided proteins assembled together. As five-sided proteins accumulated together, they formed icosahedrons that resembled soccer balls. The researchers also estimated that proteins might form a triangular samosa shape, similar to the fried South Asian snack.

Gaining insights into this process could help create bio-inspired building blocks for a variety of engineering applications that need components of different sizes and shapes.

“It’s like building with Legos. It's not desirable to use the same shape block over and over again; we need different shapes. Learning from bacteria can help us build new and better structures at this microscopic scale,” concluded Tullman-Ercek.

Source:

Journal reference:

Li, Y., et al. (2021) Computational and Experimental Approaches to Controlling Bacterial Microcompartment Assembly. ACS Central Science. doi.org/10.1021/acscentsci.0c01699.