According to recent research, a sugar-containing polymer coating can one day help repair artificial joint implants, such as hip replacements, when are damaged due to wearing away.

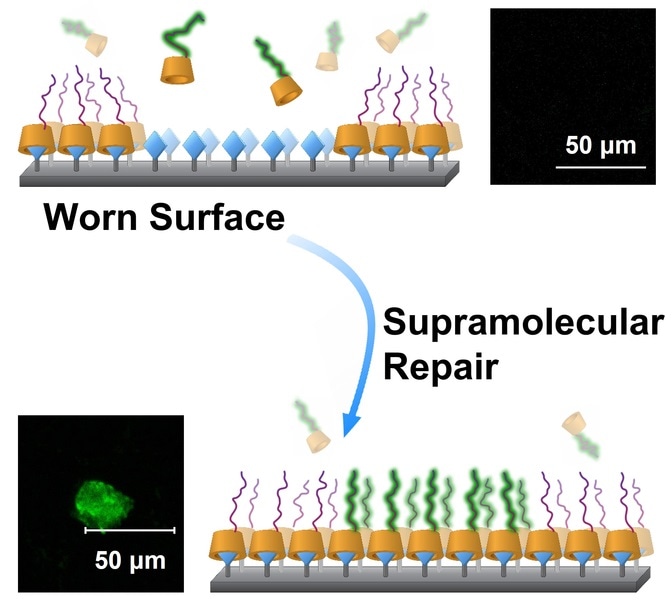

A graphical representation of the repairing surface coating and microscope images showing a repaired area in green. Image Credit: Dr Paul McGonigal and Chem.

An international group of engineers and chemists, along with Durham and York universities, UK, and Tsinghua University, China, devised the technique for effortlessly repairing low-friction surfaces.

The researchers took inspiration from how cartilage lubricates joints in humans. The scientists discovered that rings of sugar can aid a polymer to fasten onto surfaces and repair damage.

The researchers claim that their discovery can be utilized in medical implants eventually to expand the lifespan of artificial joints. The observations were published in the journal Chem.

The researchers anticipate that the coating would also be used eventually to decrease friction-caused energy waste in mechanical systems, making them much effective.

Artificial surfaces are not repaired so easily unlike cartilage being restored by human bodies when damaged.

The scientists identified that if the polymer coating they developed is rubbed from a surface at the time of use, a sugar ring present in its structure enables easy reattaching.

The coating developed by the scientist imitates the way cartilage functions to lubricate human joints.

Cartilage utilizes water to produce a slick surface that reduces wear and tear. Similarly, the new coatings persuade a layer of water to the surface, making it slippery and safeguarding the surfaces when they are knocked or rubbed.

Our sugar-containing coating gives us an appealing new way of patching up damage to low-friction surfaces. Hip and knee joints in our bodies stand up to decades of wear and tear thanks to the cartilage being repaired and replaced constantly. We have made materials that work in a similar way, but that are compatible with artificial joints.”

Dr Paul McGonigal, Senior Author and Associate Professor, Department of Chemistry, Durham University

Dr Paul McGonigal further adds, “The components of our coatings are biocompatible, which makes them exciting prospects for use in medicine. We could also imagine developing a range of these materials that work in very different environments. Avoiding and repairing the damage caused by friction is equally important to ensure that cars and other machinery last for a long time.”

The polymer coating comprises two major parts—a long molecular chain with negative and positive charges to hold on to a water layer, an effect like static electricity, and a sugar ring attached to one end of the chain. This sugar ring anchors itself to a surface by docking with specific molecules, known as adamantanes.

Upon treating titanium metal with these adamantane structures, the scientists revealed that the polymer coating gets attracted to the surface. The non-permanent, weak links formed are vital to the repair process.

Dr Yulong Sun, the co-author and a researcher in Dr McGonigal’s lab at Durham University spent time analyzing the low-friction surfaces with PhD research student Yixin Wang and Professor Hongyu Zhang in Tsinghua University’s Department of Mechanical Engineering.

Repair mechanisms are key to making materials that last a long time. Nature’s low-friction materials regenerate when they are damaged, but until now, we haven’t had good repair mechanisms for artificial systems. To tackle this challenge, we need chemists and engineers to cooperate to design advanced coating technology.”

Dr Yulong Sun, Study Co-Author and Researcher, Durham University

They also stated that currently, this kind of repair needs more polymer coating to be dissolved in the water surrounding a surface, however, they assure that the coatings would be enhanced to evade the need for the presence of this extra material.

This is dynamic yet selective chemistry, which looks like it could be an effective way to undo the negative effects of mechanical wear on joints and other surfaces. If our protective coating layer is worn off, it is restored again without needing our intervention, thanks to targeted molecular recognition.”

Dr Alyssa-Jennifer Avestro, Study Co-Author and Dorothy Hodgkin Research Fellow, University of York

Source:

Journal reference:

Wang, Y., et al. (2021) Supramolecular repair of hydration lubrication surfaces. Chem. doi.org/10.1016/j.chempr.2021.11.001.