A group of scientists from the Leibniz Institute for Food Systems Biology at the Technical University of Munich (LSB) has automated a tried-and-true technique for the delicate, artifact-free isolation of volatile food ingredients.

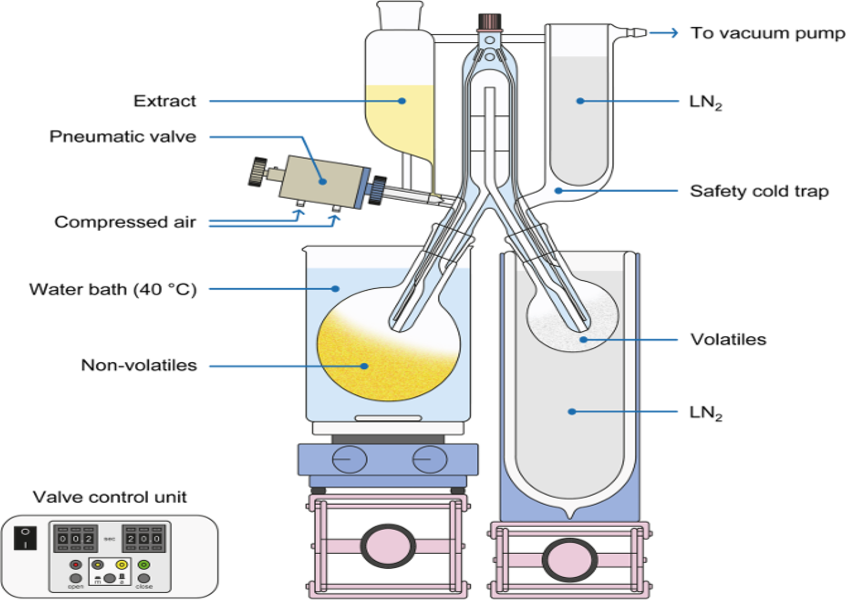

Equipment for performing an automated SAFE including the pneumatic valve and its electronic control unit Image Credit: © Schlumpberger, P. et al., 2022; CC BY 4.0

Equipment for performing an automated SAFE including the pneumatic valve and its electronic control unit Image Credit: © Schlumpberger, P. et al., 2022; CC BY 4.0

Automated solvent-assisted flavor evaporation (aSAFE), as the team’s most recent comparative study has now demonstrated, has a number of advantages over the manual procedure. On average, it produces higher yields and lessens the chance of nonvolatile substance contamination.

For odorant analysis, the optimized method is especially crucial. The sensory profile of food is greatly influenced by odorants, which also have a significant impact on eating pleasure. Therefore, understanding the primary odorants that influence a food’s aroma is important for both analytical quality control and focused product development in the food industry.

Isolating volatile compounds from food—anything but trivial

It is not easy to isolate volatile compounds from food. Numerous established techniques lead to the loss of labile odorants as well as to odor-active artifacts and hence are inappropriate for odorant research. For the first time, it was possible to easily isolate even thermally labile odorants from food without artifact formation using the manual SAFE technique that was developed in 1999.

This is an important prerequisite for using further analytical methods to identify the key odorants.”

Philipp Schlumpberger, Leibniz Institute for Food Systems Biology at the Technical University of Munich

Philipp Schlumpberger contributed equally to the research with Christine Stübner. At LSB, both are presently pursuing doctoral degrees.

Manual SAFE is now accepted as a best practice in aroma research across the globe. However, the research team recognized the need for improvement in terms of usability, yields, and lowering the risk of transferring nonvolatile material, which can seriously impede subsequent analytical steps.

The valve is critical

As we discovered, the problems are mainly associated with the manual operation of the valve on the dropping funnel. Therefore, we replaced it with an electronically controlled pneumatic valve. To fully automate the SAFE apparatus, we optionally extended it with an automatic liquid nitrogen refill system as well as an endpoint detection and shutdown system.”

Martin Steinhaus, Principal Investigator and Section and Working Group Leader, Leibniz Institute for Food Systems Biology at the Technical University of Munich

The installation of the automatic valve increased yields, specifically for lipid-rich food extracts and for odorants with relatively high boiling points, as the team's study now demonstrates. Additionally, the automated SAFE eliminates operator errors that, in the manual version, could result in nonvolatile substance contamination of isolates.

In the meantime, automated SAFE has replaced the manual variant in our laboratories. Other academic and industrial research groups are already following our example.”

Martin Steinhaus, Principal Investigator and Section and Working Group Leader, Leibniz Institute for Food Systems Biology at the Technical University of Munich

Source:

Journal reference:

Schlumpberger, P., et al. (2022) Development and evaluation of an automated solvent‑assisted favour evaporation (aSAFE). European Food Research and Technology. doi.org/10.1007/s00217-022-04072-1.