Produced in Partnership with RETSCH GmbHReviewed by Emily MageeApr 4 2023

Cannabis is categorized as a “soft” drug which potentially decreases the inhibition threshold for consuming “hard” drugs such as cocaine or heroin. In 1925, cannabis possession was prohibited globally, but today, limited consumption is legal in several countries, such as the Czech Republic, Canada, and Israel.

The first country that legalized the sale, cultivation, and distribution of cannabis was Uruguay in 2013. The advantages of cannabis for medical treatment are proven by various studies,1 and numerous countries have begun the process of legalizing cannabis use under strictly regimented conditions.

The purchase of cannabis for medical reasons has been legal since 2016 for 29 states in the US, with it being legalized one year later in Germany.

The health benefits of cannabis can be categorized into five clusters:

- Pain and/or sleep

- Gastro-intestinal

- Neurological

- Mood and behavior

- Other

The main ingredients of cannabis are cannabinoids such as cannabinol (CBN), tetrahydrocannabinol (THC), or tetrahydrocannabivarin (THCV), which may act as a sedative, appetite suppressant, or psychoactive compounds.

These have advantageous effects, for example, on metabolic disorders such as pain relief, diabetes, anti-inflammatory processes, or even for the treatment of bacteria like MRSA. Cannabis also has a positive influence on diseases such as Tourette’s syndrome, HIV, arthritis, asthma, Alzheimer’s, cancer, or multiple sclerosis.

Another sizable group of ingredients is the terpenoids such as D-Limonene, Linalool, and α-Pinene. These cause the “entourage effect,” meaning they have the ability to enhance or alter cannabinoid uptake in the Blood-Brain-Barrier. Additionally, terpenoids act as antioxidants or anti-inflammatory agents.

The concentrations of terpenoids and cannabinoids are the key areas of interest in the quality control of products related to cannabis. These are typically detected via HPLC analysis.

Another area of interest is pesticide content. Cannabis takes a range of edible forms, such as concentrate, ground leaves, or related products, such as cookies or jelly bears. To guarantee reliable analytical results, the sample preparation process for cannabis must be adaptable to the significant complexity of the various matrices.

There are several difficulties that may arise, such as samples being fibrous, sticky, or fatty, in addition to the sample amount varying significantly. Although the use of cannabis for medical treatment is growing, in most countries, it still remains illegal, with possession and sale being criminal offenses.

As a result, both the quality control for medical applications and the analysis of the active components in a penal context are crucial. In drug offense trials, the expertise on the drug’s active components has considerable influence on the penalty.

For example, for cannabis, a content in excess of 7.5 g tetrahydrocannabinol (THC) is already deemed critical. The local Office of Criminal Investigation typically provides the expertise.

Pre-cutting of Dried Hemp Plants in the Cutting Mill SM 400

The grinding chamber volume of the Cutting Mill SM 400 is 7.5 liters and accepts sample pieces sized at most 170 mm x 220 mm. As a result, large sample volumes are fed and fully homogenized within a very short time. Manual pre-cutting is generally not needed.

Due to the substantial grinding chamber volume, the wide opening of the hopper, and the large 240 mm x 240 mm surface of the bottom sieves, the throughput is considerably higher than smaller models. Additionally, the SM 400 can accomplish grind sizes down to 1 mm depending on the sample material.

100 kg of dried hemp with an original particle size of up to 60 mm was cut batch-wise to a fineness less than 20 mm within 60 minutes, with the use of a 20 mm bottom sieve. The SM 400 is the only mill to quickly process such vast quantities of fibrous material without wedged pieces causing blockages of the hopper.

Following this, the pre-cut sample can be pulverized, for example, in RETSCH’s Ultra Centrifugal Mill ZM 200. In addition, the SM 400 is appropriate for milling all parts of the plant for easy ‘rolling’ or filling of material into a range of objects for smoking.

Figure 1. Cutting Mill SM 400. Image Credit: RETSCH GmbH

Figure 2. Initial hemp sample (left) and after size reduction in the SM 400 XL (right).

Image Credit: RETSCH GmbH

Sample Homogenization in the Ultra Centrifugal Mill ZM 300

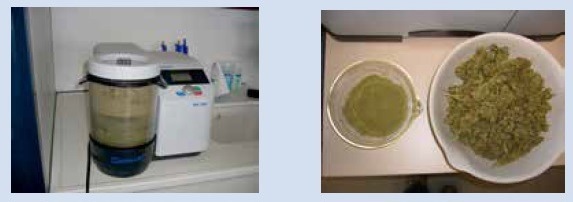

The Ultra Centrifugal Mill ZM 300 is the perfect mill for the pulverization of granules such as grains or fibrous samples like hemp plants. It reaches a top speed of 23,000 minute-1 and can be equipped with a wide range of accessories, meaning that it can be adapted to the requirements of the sample.

The shearing forces between the ring sieve and the rotor enable effective size reduction of fibrous materials. Hemp contains oil, making it a temperature-sensitive material. To minimize heat build-up during grinding, the utilization of a distance sieve is advised.

Thanks to a small gap between the sieve and the rotor, the shearing forces and the formation of heat are reduced. Using a 0.5 mm distance sieve at a speed of 23,000 minute-1, 20 g of the precut hemp flowers can be ground to a particle size of less than 0.5 mm.

Using a cyclone has a cooling effect on the sample and helps efficiently discharge the material from the grinding chamber. The pulverized sample is now ready for, e. g. extraction of pesticides with the QuEChERS method.

Figure 3. Ultra Centrifugal Mill ZM 300. Image Credit: RETSCH GmbH

Figure 4. After pre-cutting in the SM 400 (left) the sample is pulverized to <0.5 mm

in the ZM 300. Image Credit: RETSCH GmbH

Pesticide Extraction with the Mixer Mill MM 400 (QuEChERS Method)

The QuEChERS method (“quick, easy, cheap, effective, rugged and safe”) was created to make the process from sample preparation to pesticide residue analysis more efficient. It is comprised of three steps: homogenization, extraction, and analysis.

Care is required during the homogenization process to ensure that the sample does not get too warm, as some pesticides are volatile. Following the homogenization, extraction of 10 g of the pulverized hemp sample takes place with 10 mL of acetonitrile. Subsequently, using chromatographic analysis, the organic phase is dried and tested for pesticides.

Extraction of the sample takes place in the presence of a salt mixture (such as sodium chloride and magnesium sulfate in a ratio of 1:2) to inhibit ghost peaks in the chromatograms. To transfer the pesticides into the organic phase from the sample, the mixture is agitated with salt and acetonitrile for between 1 and 3 minutes.

This agitation may occur in a laboratory mill such as RETSCH’s Mixer Mill MM 400. It shakes the sample in a 50 mL Falcon tube with up to 30 Hz frequency, guaranteeing complete mixing of the sample to enhance subsequent extraction.

Figure 5. Mixer Mill MM 400 with adapter for 8 conical centrifuge tubes.

Image Credit: RETSCH GmbH

Pulverization of Hemp in the CryoMill or the MM 500 Vario for Subsequent Pesticide Analysis

Extraction using QuEChERS may be enhanced by the reduction of the particle size to less than 0.5 mm. As a result of the sticky and oily properties of the sample, the Ultra Centrifugal Mill is not appropriate to achieve this.

Embrittling the sample, e.g., with liquid nitrogen, is an efficient way to easily break down oily materials.

Cryogenic grinders like RETSCH’s CryoMill are specially designed for these applications, as they continuously cool the grinding jar, and thus the sample, with LN2.

The CryoMill achieves grind sizes less than 0.1 mm, meaning that higher pesticide quantities are measured for the hemp sample following extraction than in the ZM 300, for example. 5 g of pre-cut hemp samples were ground in a 50 mL stainless steel grinding jar using one 25 mm grinding ball made of stainless steel.

The sample and ball were placed in the grinding jar with the lid closed tightly closed and the jar clamped into the CryoMill. An automatic function for pre-cooling confirms that the grinding process only begins once a temperature of -196 °C is attained and maintained. The pre-cooling time was set to 3 minutes at 5 Hz.

Grinding was carried out at 30 Hz for 3 minutes. Due to the CryoMill’s autofill system, the user never encounters liquid nitrogen, and the machine maintains the temperature at -196 °C throughout grinding. Following embrittlement, the sample may be ground to much smaller particles than in the ZM 300.

For larger sample amounts, however, the ZM 300 is an appropriate selection. An alternative option for cryogenic grinding is employing the Mixer Mill MM 500 vario, which accommodates six grinding jars with a maximum volume of 50 mL.

The process is similar to that of the CryoMill, with the exception that embrittlement of the sample occurs in a bath with liquid nitrogen. After 3-5 minutes, the liquid nitrogen stops boiling, and the six grinding jars with the sample may be positioned in the

MM 500 vario and pulverized for two minutes at 35 Hz.

Figure 6. CryoMill with 50 l dewar. Image Credit: RETSCH GmbH

Figure 7. The hemp sample milled in the CryoMill (left) yields a higher pesticide amount after extraction than the sample milled in the ZM 300 (right). Image Credit: RETSCH GmbH

Rapid Pulverization of Eight Samples of Flower Buds with Almost No Residues for Extracting THC/CBDs

Testing laboratories require reliable solutions for the grinding of multiple cannabis samples each day, with the quantity of sample being ground varying from 4 to approximately 30 g per sample.

Labs also frequently face challenges due to sampling residues because flower buds are sticky as a result of their oily content. This means cleaning efforts are a time factor for testing labs. A classic grinder is frequently utilized, as the residues are in a tolerable range.

Grinding 30 g flower buds requires around 15-30 minutes, depending on the properties of the sample, and cleaning requires another 5-10 minutes. The Mixer Mill MM 400 may be equipped with 8 x 50 mL Falcon tubes, offering a very comfortable and rapid solution.

Approximately 4 g of flower buds may be ground per tube, giving 32 g in one run if larger sample quantities or up to eight different samples are needed. Sample material and grinding balls are frozen at -22 °C prior to grinding.

Two 15 mm grinding balls made of stainless steel are added to each tube, and grinding is subsequently conducted at 25 Hz for two minutes. Cleaning of the balls is simple- they simply need to be rinsed with acetone, while the tubes are disposed of following use.

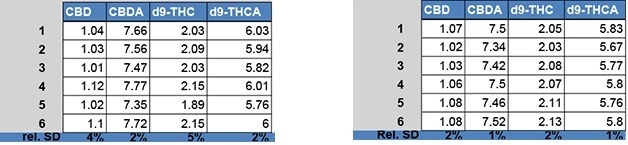

Sample loss occurs in a range of 4-5%, which is deemed tolerable. Despite the time factor, the MM 400 delivers an additional benefit compared to the Grinder: the relative standard deviation is generally less in samples homogenized in the MM 400, e.g., from 5% to 2% in the case of d9-THC.

Results after homogenization in a Grinder (left) and in the MM 400 (right) - /g/100g)

In a classic grinder, 32 g of sample (or 8 x 4 g) flower buds were ground for up to 30 minutes. Only two minutes of grinding was required when the MM 400 and the falcon tube adapter were used. Despite the more than 10-fold faster grinding, the sample was better homogenized in the MM 400, resulting in only half of the standard deviation achieved by using the classic grinder.

Small Scale Production of Ground Cannabis in the SM 300 316L foodGrade

Retsch supplies an SM 300 316L foodGrade for small-scale production. All parts that come into contact with the sample are made of 316 L, including the parallel section rotor and the bottom sieve, and the long stock hopper.

Up to 20 kg/hour of dried cannabis plants may be ground at 3000 rpm with the use of a 4 mm bottom sieve to a fineness predominantly less than 6 mm. A comparable result could be achieved with flower buds.

Here, the utilization of the V-rotor is advantageous, which is not yet available in 316 L, but it enables the grinding of 18 kg/hour of sticky flower buds to approximately 2 mm particles. The decrease in speed to 2000 rpm helps prevent sample warming and, thereby, blockages of the apertures of the sieve.

Figure 8. Cutting Mill SM 300 316L foodGrade: All parts coming in contact with the sample are made of 316L for food or pharma grade applications. Image Credit: RETSCH GmbH

Homogenization of Edibles in Ball Mills such as CryoMill or MM 400

Food samples that are sticky or fatty may cause blockages in the mill at room temperature. As a result, cryogenic grinding either in the CryoMill or the MM 400 is the best route to avoid sample caking and the loss of volatile ingredients.

Sample volumes like one to two cookies or a few jelly bears are best homogenized in the MM 400. This ball mill is ideal for the homogenization of sample volumes up to 2 x 20 mL in less than 1-2 minutes. It is crucial to first fill the jar with the grinding ball(s) and the sample and tightly close the lid before embrittling.

Care is required to ensure that no LN2 is enclosed within the grinding jars, as the evaporation of LN2 would cause a substantial pressure increase inside the grinding jar. The enclosed grinding jars and the contained sample undergo embrittlement in an LN2 bath for 2-3 minutes.

Grinding jars suitable for cryogenic grinding are made of PTFE or steel. As a result of the high energy input and the resultant frictional heat, the grinding process should not exceed 2 minutes to prevent the sample from warming up and to preserve its breaking properties.

If longer grinding times are necessary, these should be interrupted by intermediate cooling of the closed grinding jars in the MM 400.

Five pieces of jelly bears underwent pulverization in the MM 400 in a 50 mL grinding jar using a 25 mm stainless steel grinding ball. The closed jar was immersed in an LN2 bath for around 4 minutes, then clamped into the mill. After 90 seconds at 30 Hz, the sample was fully pulverized to a fineness of 0.3 mm.

Figure 9. Jelly bears before (left) and after cryogenic grinding in the Mixer Mill MM 400. Image Credit: RETSCH GmbH

Cryogenic grinding in the CryoMill provides the benefit of continuous cooling of the grinding jar with liquid nitrogen. This consistent temperature is guaranteed for even long grinding times without requiring intermediate cooling breaks. For heavy-metal-free grinding, a zirconium oxide grinding jar should be utilized.

One praline, a few pieces of licorice, or similar samples usually undergo pulverization in the CryoMill.

Homogenization of Cookies in the Knife Mill GM 200

The Knife Mill GM 200 was created for the thorough homogenization of samples that have high oil, sugar, water, or fat content. It allows sample volumes of up to 700 ml.

Due to the powerful 1000 W drive, the mill is able to homogenize even difficult samples rapidly and efficiently without any blockages or more than two grinding steps. The pioneering Boost function enables a temporary speed increase to 14,000 minute-1, allowing additional power for the homogenization of difficult samples in a very short time.

The mill can be operated in three different modes. The standard mode enables cutting, the reverse mode achieves impact, and the interval mode provides enhanced sample mixing. This optimizes the homogenization process in terms of material properties.

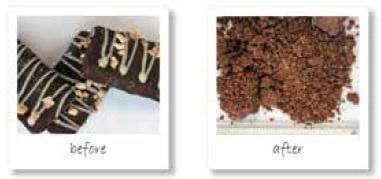

Up to eight programs can be stored for routine applications. The option to save four program sequences is useful when using two grinding steps, for example, pre-crushing in impact mode, subsequent fine grinding in cutting mode, or if two different speeds are needed. Pulverization of eight large cookies was conducted in two steps.

In the pre-grinding step at 4,000 minute-1, the interval mode was employed for 10 seconds to improve the mixing of the sample. The utilization of the standard lid guarantees that the sample may freely move in the container, decreasing the heat development (and the subsequent release of fat).

In the homogenization step, which requires 35 seconds at 10,000 minute-1, the utilization of the reduction lid 0.5 l is preferred to force the sample toward the blades and improve the grinding efficiency. The complete sample was homogenized to less than 0.5 mm in this manner.

Figure 10. Knife Mill GRINDOMIX GM 200. Image Credit: RETSCH GmbH

Figure 11. Cookies before (left) and after pulverization in the Knife Mill GM 200 (right).

Image Credit: RETSCH GmbH

Field Experience

Homogenization of large sample volumes of cannabis in the Knife Mill GM 300 at the Criminal Investigation Office in Dresden, Germany

In the lab of the Regional Office in Dresden, cannabis plants are initially reduced in size and then undergo extraction of several part samples of the ground material.

The extracts are subsequently analyzed via gas chromatography.

We usually deal with large sample volumes”

Thomas Paulick, Laboratory Manager, Dresden’s Regional Office of Criminal Investigation.

Thomas further describes, “Therefore, it is essential to extract a representative part from the entire sample amount, to ensure a reliable quantification of the active component. The GM 300 fulfills this requirement: from up to 4 liters of plant material we receive a homogeneous sample from which we can then take approximately 0.5 g for further analyses.”

“We process leaves with remnants of thin twigs as well as highly resinous blossoms without cooling – which is no problem for the knife mill. Grinding time and speed are selected according to the properties of the plant.”

“The closed design and removable grinding container help to reduce the formation of dust during homogenization. To sum it all up, the new GM 300 has proven to be highly suitable for our requirements.”

Image Credit: RETSCH GmbH

Conclusion

With the use of cannabis in the medical sector growing, quality control has become a vital issue. Sample homogenization prior to analysis is a critical step to guarantee meaningful and reliable analysis results.

RETSCH provides a variety of different laboratory mills for efficient, neutral-to-analysis sample preparation, which are highly appropriate for such a task.

Acknowledgments

Produced from materials originally authored by Dr. Tanja Butt at Retsch GmbH.

References

- https://cannabis-med.org/

About RETSCH GmbH

With more than 100 years of experience in sample preparation, RETSCH is the world’s leading manufacturer of instruments for homogenizing laboratory samples for analysis as well as for analyzing the particle size of solid substances by test sieving.

The RETSCH product portfolio includes a great variety of mills and jaw crushers, capable of reducing materials down to any required fineness, sieve shakers and test sieves as well as assisting technologies to optimize the handling of samples.

RETSCH instruments stand for representative sample preparation in compliance with relevant standards and contamination-free comminution processes – they are essential tools for preparing samples for laboratory analysis and stand for reliability, precision and durability.

Since 1990 RETSCH is part of the continuously growing technology group VERDER and forms the core of the group’s Laboratory Division VERDER SCIENTIFIC. Other companies belonging to this division are Retsch Technology GmbH, ATM GmbH, Eltra GmbH and Carbolite Gero Ltd.