A cornerstone of modern biotechnology and industrial microbiology, bioreactors are essential for synthesizing and producing chemicals like vaccines, enzymes, proteins, and antibiotics.

Image Credit: H.E.L Group

Bioreactors, at their core, are specific vessels that have been designed to provide a controlled environment. This environment features the ideal conditions needed for the growth and cultivation of cells, microorganisms, or enzymes.

Therefore, the desired product's quality and quantity are controlled thanks to the careful design and operation of the bioreactors, which permit the optimization and control of these conditions, such as temperature, oxygen concentration, pH, and nutrient supply.

Although bioreactors have been in the spotlight for a few decades, they have, in fact, been used for over 10000 years. However, they did not start to gain momentum in industries such as pharma and biotech until the 1950s.

Since then, bioreactors have evolved significantly in design, scale, and applications, becoming indispensable tools for producing a wide range of biological products. This article will outline various types of bioreactors and their applications.

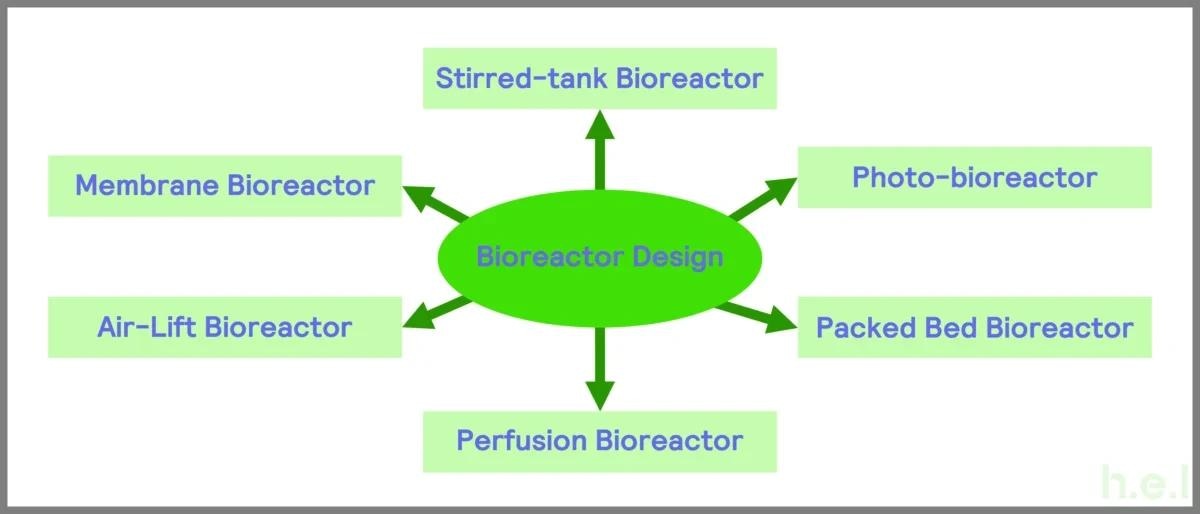

Bioreactor Designs

Stirred-tank bioreactors, or STRs, are made up of cylindrical vessels in which an impeller agitates the fluids to achieve conditions as close to homogeneity as possible. Highly versatile, the applications of STRs include cultivating animal, microbial, and plant cells to produce vaccines, proteins, and biofuels.

BioXplorer 100 – an example of a bioreactor operating in a stirred-tank configuration. Image Credit: H.E.L Group

Stirred tank reactors were the first modern reactors to be developed, and their design continues to be optimized for efficiency, scalability, and product yield.

Air-Lift Bioreactor (ALR)

Air-lift bioreactors are similar to STRs, and are also designed as cylindrical vessels. The main difference between the two types of bioreactors is that air-lift bioreactors, instead of relying on impellers, contain an aeration system and a draft tube, which will bring air bubbles to the bottom of the reactors.

The air bubbles increase the oxygen transfer and mix in a loop as they move upwards. Air-lift bioreactors are primarily deployed for use in shear-sensitive cells, like animal cells, and low-density products, such as enzymes and metabolites. Other applications include biofilm cultivation and wastewater treatment.

Packed Bed Bioreactor (PBR)

PBR bioreactors take the form of columns filled with solid support material, ranging from pellets to fibers or beads. These support materials then provide a support surface for microbial growth. The establishment of biofilms is permitted by the packed material, and this will be fed fresh medium as it is pumped into the column.

Packed bed bioreactors are routinely used for the production of extracellular enzymes and pollutant removal from wastewater. A key advantage of this type of reactor is that it offers productivity at a low cost and with a simple operation.

Membrane Bioreactor (MBR)

MBR bioreactors combine membrane filtration and biological treatment into a single process. The biomass from the liquid culture medium is filtered out by the membrane in the MBR filters, which permits clarification of the medium without needing a further clarification step. As MBRs can remove pollutants, organic matter, and potential pathogens, they are extensively used in wastewater treatment.

Photo-bioreactor (PBRs)

Photo-bioreactors have been carefully designed to provide the optimal environment for cell proliferation. In the case of PBRs, this design goes a step further and adds light control to cultivate photosynthetic organisms, including cyanobacteria and microalgae.

The design of the PBRs allows them to optimally produce large amounts of biomass used for animal feed. Advances in the genetic engineering of photosynthetic cells have also allowed for the production of strains specialized in synthesizing biofuels and pharmaceuticals.

Perfusion Bioreactor

Designed to maintain continuous cell cultures, perfusion bioreactors are ideally suited for the cultivation of high-density cells, such as mammalian cells.

In continuous reactors, part of the cell cultures is lost from the vessel as media is removed to allow replenishment with fresh media. However, using hollow fibers or packed bed systems in perfusion bioreactors allows for the removal of the media, leaving the cell culture in the reactor.

Perfusion bioreactors can be used for the growth of mammalian cells and tissues for the production of modified proteins.

Image Credit: H.E.L Group

Bioreactors: Bridging the Past and the Future

Bioreactors have accompanied humans for the last 10000 years in one way or another: first in their culinary explorations, improving the preservation and organoleptic characteristics of ingredients and foodstuffs.

As noted, the application of bioreactors in bioprocessing has expanded greatly since the 1950s, which has seen use in everything from the production of pharmaceuticals to biofuels. The design and optimization of specific types of bioreactors have arisen as a result of this broad range of applications, each with its specific use and unique advantages.

The field of bioreactor design has changed and evolved yet again in recent years. One trend in development is the utilization of single-use bioreactors, offering advantages such as reduced contamination risk, faster turnaround times, and reduced operating costs.

Other trends are the development of modular systems, allowing an easier transition of parallel operation and scale-up. Overall, bioreactor design is a fascinating field in which continuous developments and innovations are the driving force to enhance efficiency, scalability, and sustainability.

About H.E.L Group

H.E.L develops and manufactures innovative scientific instruments and software designed to optimize the efficiency, safety, and productivity of key processes in chemistry and biology applications.

The H.E.L team of 70 includes highly skilled process and software engineers, based at their extensive research and manufacturing facilities in the UK, as well as sales and support offices around the world.

H.E.L has a long history of solving complex challenges for customers. Since 1987, the Company has worked with businesses and laboratories globally, providing proprietary automated solutions for the pharma, biotechnology, chemical, battery, and petrochemical sectors.

We continue to extend the reach of our products and service to support and enable R&D and process optimization further across Europe, the US, China, and India.

H.E.L is accredited with ISO 9001 : 2015

Sponsored Content Policy: AZoLifeScience.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.