What is additive manufacturing and why is it important?

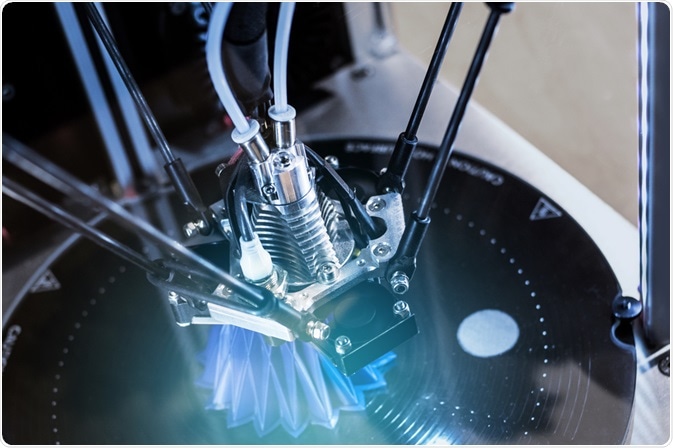

There are several types of additive manufacturing and many applications, but the main principle is commonly known as 3D printing. This is where layers upon layers of material are stacked and fused on top of each other to form a product, and controlled digitally by 3D software.

Image Credit: BLACKDAY/Shutterstock.com

Image Credit: BLACKDAY/Shutterstock.com

Pharmaceuticals are normally produced through several basic processes such as tableting, or tablet compression, where powders are compressed into a more solid tablet form. These processes offer many disadvantages that can be avoided through the use of additive manufacturing, whilst also providing flexibility and ease of design.

Advantages of additive manufacturing of pharmaceuticals

One main advantage of using this technique for pharmaceutical manufacturing is that pharmaceuticals can be easily tailored for each patient. This is achieved through changing the release profile of the pharmaceutical, which essentially means adjusting when and for how long the active agent is released into the body.

This can be adjusted by changing the relative quantities of the active and inactive form of the constituents or by compartmentalizing or layering the tablet to change how drugs are released in the patient’s body.

Another main advantage is the potential for on-demand drugs. In an emergency situation, it will be much easier to produce medicine for a patient as it can be printed in a hospital environment, rather than relying on the stocks containing a drug with the correct dose and release profile.

Long term stability of a drug would be less important, as they can be printed as soon as they are needed, so it would be possible to design more effective drugs with faster action, as they don’t need a long shelf life.

All of these changes would normally be impossible or very difficult to achieve through conventional methods, as it would involve changing the entire manufacturing process.

The ‘polypill’

With additive manufacturing still being a fairly recent technology, it is being developed and expanded every year. As this technology advances, there is the possibility to produce a ‘polypill’ where several pharmaceuticals can be combined into one pill by printing in different compartments.

This will make it easier for patients, especially the elderly, who need to take several pills every day. Self-administered treatment could, therefore, be simpler and more reliable, as one pill could not be forgotten occasionally.

Current 3D printed pharmaceuticals

In the USA, there is one FDA approved drug, Spritam®, which is 3D printed. It is an epilepsy drug approved in August 2015 and is designed so that it disintegrates instantly after ingestion. This attribute is only possible through the precise printing of the drug, and would not work when the drug is assembled by compression.

The capabilities of additive manufacturing in pharmaceutical production allow a high level of control over when a drug is released within the body and how the pharmacodynamics of the drug can be altered by changing its composition and shape.

Combination products and medical technology

How pharmaceuticals are delivered in the body is also an important application for additive manufacturing. Drug-device and drug-biologic combination products are where a pharmaceutical is used or administered with the use of medical devices or other biological products.

Many medical devices are used in the delivery of pharmaceuticals or in other medical scenarios, and additive manufacturing can be used to 3D print these devices.

As well as 3D printing offering faster production, another advantage is that the materials used can be more specialized, such as producing a device that releases a drug or antibiotic into the patient. One example of where this technology is being developed is catheters that contain an antibiotic or other pharmaceuticals that can prevent the formation of biofilms and keep the procedure more sterile.

There has also been research into the 3D printing of drug capsules that can be remotely triggered to release their contents. This would offer a huge advance in the ability to control how and where drugs are distributed in the body.

Another common application of additive manufacturing in this area is the production of medical scaffolds, which release drugs into nearby tissue to allow for pharmacologically controlled engineering of tissues.

For example, printing a scaffold inside a patient to help with bone repair and regeneration, but using materials that include an active agent such as dexamethasone. This can support the weak or damaged bone, as well as promoting growth and repair.

Further Reading