Polymers are long-chain molecules consisting of repeating subunits of macromolecules, which have found themselves in many uses. One such important use is its role in drug delivery. Due to polymers, recent advancements in drug delivery technology have seen the development of controlled release of drugs over long periods, and many mechanisms have facilitated this.

Image Credit: Love Employee/Shutterstock.com

Drug Delivery

Drug delivery refers to the various ways a drug is transported to its desired target for the drug to induce therapeutic effects. For a given drug to be efficacious, it must be within a specific range in terms of its plasma concentration level - below this range, the drug would be ineffective, whereas, above this range, the drug becomes toxic.

Typically for patients to maintain this desired range for drug efficacy, the drug dosage would need to be administered between intervals. This could be problematic as it can require the patient's responsibility to take a given drug at certain periods, whereby patient compliance could be poor, which is often the case.

The controlled-release method provides a drug release rate close to constant, thus kinetically known as zero-order controlled release. Pumps and polymers often dictate this controlled-release technology. Drug delivery systems based upon polymers usually work via the polymer's biodegradation rate, which in turn brings about the diffusion of the drug from the polymer matrix.

The resulting period in which the therapeutic agent is released is days, and sometimes even years, whereby the drug plasma concentration remains within the therapeutic range. In addition, environmental conditions influencing the rate of drug release are negligible, thus permitting a drug release rate that is more stable.

Another advantage of the controlled-release method is the ability to precisely target the drug at a specific area of the body for its therapeutic benefits - such as specific organs, tissues, and cells, reducing off-target effects and side effects of the therapy.

Polymer controlled-release drug delivery systems

With the polymeric controlled-release drug delivery system, there are several ways in which this can be achieved.

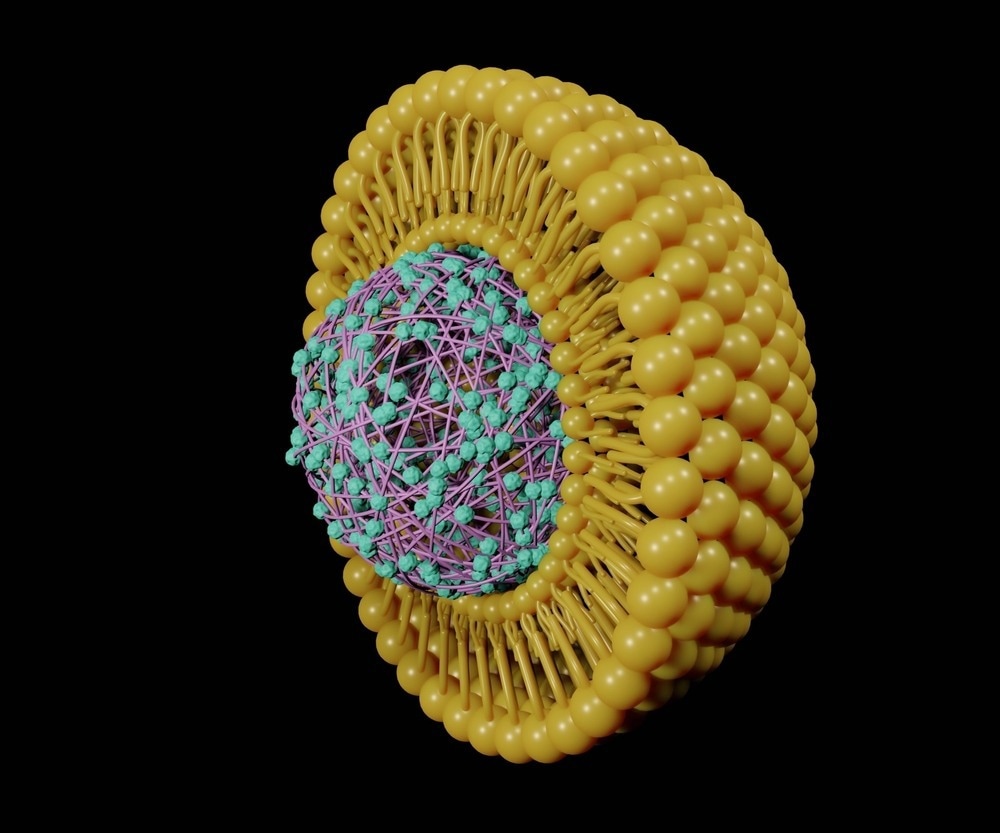

Diffusion-controlled mechanism

The first of which is the diffusion-controlled mechanism. There can be two systems in which this can be realized: via the reservoir system or the non-erodible matrix system. The reservoir system can be in the form of capsules, microcapsules, hollow fibers, and membranes, whereby the drug is encapsulated within the polymer (such as silicone, ethylene-vinyl acetate, and hydrogels), and thus the polymer surrounds the drug. Diffusion through the polymer allows for steady and slow release of the drug over long periods.

In contrast, the non-erodible matrix system, which also relies upon diffusion for drug release, has the drug dispersed in the polymer. However, this means that steady release is more difficult to achieve than the reservoir system. One advantage of the non-erodible matrix system over the reservoir system is its safety profile. With a sudden breakage or tear of the polymer system, less drug leakage would result as it is embedded in the polymer, lowering the chances of toxicity.

Chemically-controlled mechanism

In addition to the diffusion-controlled mechanisms, there are also chemically controlled mechanisms. This may involve chemical reactions that result in the gradual drug release via the complete dissolution of the polymer that encapsulates the drug, known as the bio-erodible matrix system.

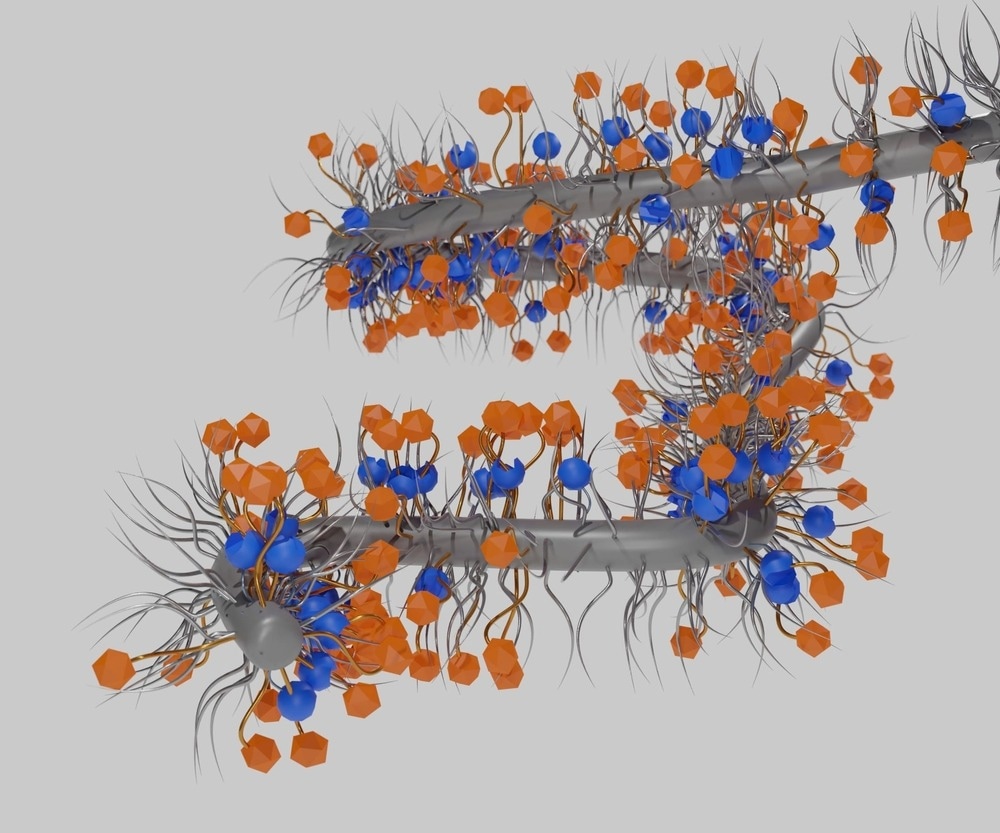

Another chemically controlled mechanism is the covalent polymer-drug conjugate, whereby drugs are bonded to a polymer backbone and rely on water or an enzyme to cleave the drug-polymer backbone bond for drug release.

Image Credit: Love Employee/Shutterstock.com

Solvent-controlled mechanism

Furthermore, there is the solvent-controlled mechanism. One involves water diffusion into a hydrophilic polymeric system within an aqueous environment, such as body fluid. This induces the swelling of the polymer and, in turn, promotes the release of the drug, which is dissolved in the polymer. Known as swelling-controlled release, the drug release rate depends on the water diffusion rate and the polymer's chain relaxation rate.

In addition, a system built around an osmotic pump has also demonstrated effectiveness in bringing about controlled release. The osmotic-controlled release system involves a carrier, such as a tablet, covered in a semi-permeable membrane with laser-drilled holes. The drug, dissolved in polymer, is released via the holes as water flowing through the semi-permeable membrane produces osmotic pressure, and thus, in essence, the active drug is pushed out [2]. Given the concentration gradient across the membrane remains constant, a zero-order controlled release is maintained.

Conclusion

Throughout these different mechanisms and systems of polymeric drug delivery, the end goal Is the same, that is, creating a viable and safe method for the controlled release of a drug, thereby producing a drug release profile that follows zero-order kinetics. It provides a more convenient way of delivering a therapeutic agent to its target, and with a drug release rate close to constant, the drug safety profile also improves by reducing the fatal occurrence of toxic dosage.

Sources:

- Kamaly N, Yameen B, Wu J, Farokhzad O. Degradable Controlled-Release Polymers and Polymeric Nanoparticles: Mechanisms of Controlling Drug Release. Chemical Reviews. 2016;116(4):2602-2663.

- Yang, W. and Pierstorff, E., 2012. Reservoir-Based Polymer Drug Delivery Systems. SLAS Technology, 17(1):50-58.

Further Reading