According to the father of mass production, Henry Ford, “Most people spend more time and energy going around problems than in trying to solve them.”

Laboratories are reopening worldwide following the COVID-19 pandemic, but global disruption remains. The pandemic led to the delay of research and unstable supply chains, while the social distancing guidelines resulted in decreased capacity at research facilities.

The next big challenge is to resume our science safely and effectively while combatting the issues surrounding inefficiency, supply chain, and sustainable research.

This article looks at how these problems can be resolved rather than avoided, using automation to compensate for lost time and to create a greener laboratory for the future.

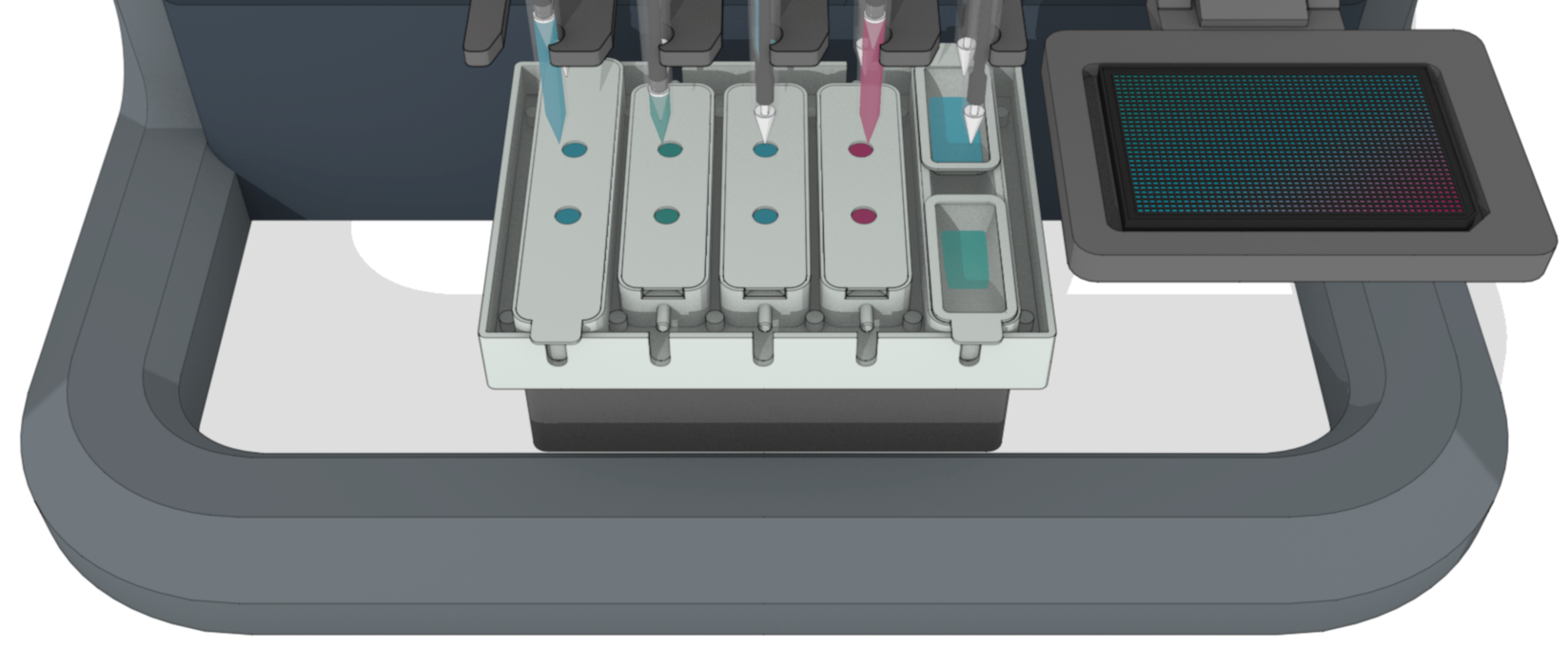

Image Credit: SPT Labtech

Advantages of Automation

There are three main advantages of automation:

- Scientists are released from repetitive processes to spend more time researching

- Enhanced accuracy and reliability relative to manual handling

- Higher throughput, which provides greater experimental power

Despite this, the barriers to adopting automation and achieving robust and reproducible data remain misunderstood.

Robotic liquid handlers are not fragile instruments that demand vast temperature-controlled laboratories. Many liquid handlers are designed for everyday benchtop use with the scientist in mind instead of a software engineer.

Widely used liquid handling processes are easy to be programmed. At the same time, quick and effective user training means the devices can be used immediately without requiring specialist education in software.

The return on investment of an automated platform is immediate. These platforms enable scientists to spend more time interrogating datasets, which substantially increase in size with automation.

Automation eliminates the limitations associated with manual pipetting, effectively removing human error, and strengthening the reliability and replicability of data.

The researcher can be more creative with their Design of Experiments, with multifactorial experiments being simpler to perform than manual handling. The outcome is not only an increase in data but better data.

More obvious advantages appear when utilizing lower liquid volumes and precision instrumentation. The supply chains of research materials, such as plastic consumables like assay reagents and tips, were affected by the disruption caused by the COVID-19 pandemic.

Miniaturizing protocols save the cost of plastic pipette tips and reagents, particularly where precision instrumentation enables the reuse of tips. By employing these processes, a laboratory can accomplish much more with a lot less.

How Automation Can Work for You

Automation is not re-creating what is done by hand. Mechanical precision provides novel possibilities for experimental design and miniaturization of protocols, and using the correct device also saves both materials and time in the process.

Common processes from kits may be streamlined to the addition of reagents to a sample. The tedium of these protocols is favorable to an automated workflow. How do we start making automation work for us?

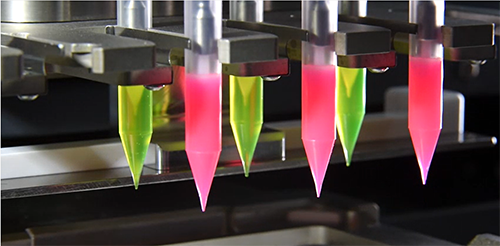

Image Credit: SPT Labtech

The first step is the identification of protocols that are frequently employed and involve time-consuming liquid handling steps. Likewise, any protocol susceptible to error or that demands careful tracking of multiple samples is appropriate for automation.

DNA library preparation, next-generation sequencing, protein crystallization, PCR preparation, and small molecule screening are popular laboratory processes that may be easily moved to automated workflows.

Specialized robots, such as the mosquito® and the dragonfly® (from SPT Labtech), utilize positive-displacement technology to consider surface tension and viscosity, as both significantly affect liquid handling at low volumes.

Standard air-displacement pipettes are sensitive to environmental pressure changes, while positive-displacement tips cooperate with a piston which forms a solid sterile ‘cap’ in the pipette tip to directly dispense the reagent or sample.

This enables the mosquito and the dragonfly instruments to achieve precise and accurate volumes rapidly and reliably within the nL – μL range.

Image Credit: SPT Labtech

With a unique non-contact ‘injection’ system to dispense liquid, the dragonfly discovery’s injection speed can be slowed down for sensitive applications, while a 400 μm-wide tip nozzle guarantees decreased shear force on fragile samples, including DNA and cells during pipetting.

A single tip on the dragonfly can hold up to 4 mL of reagent and dispense aliquots rapidly, filling a 384-well plate in less than 30 seconds when dispensing from several channels in parallel.

The dragonfly is non-contact, which enables the reuse of tips. This is not the standard for air displacement liquid handlers and helps to decrease plastic waste.

Homogenization of the sample takes place using turbulent mixing from the diffusion and injection at low volumes. The mosquito has the optional function of mixing by pipette tip, which is beneficial for low-volume applications that need homogenization.

Sustainable Science

Scientific research has a significant problem regarding plastic waste. All single-use plastic and nitrile gloves total approximately 5.5 M metric tons of waste each year. Testing for COVID-19 demonstrates this, since six plastic pipette tips are needed for each test – one for the sample and five for reagents.

With millions of tests conducted globally on a daily basis, the tip waste from COVID-19 testing is outstanding. Recycling is seldom an option in a lab setting, so how can automation help science overcome its dependence on plastic?

The most feasible options are the minimization of tip use and the maximization of tip reuse. Due to their precision and reliability, automated platforms yield fewer errors than manual pipetting, which contributes to reducing tip consumption.

However, many automated liquid handlers utilize pressure and valve-driven systems or air displacement tips, leading to similar quantities of tip waste to manual handling.

Positive displacement pipetting, like the dragonfly’s non-contact injection system, enables the reuse of tips for dispensing common reagents thousands of times without introducing cross-contamination risks.

Positive displacement pipetting delivers enhanced volumetric precision and accuracy in comparison to the others, which often require replacement or cleaning.

Volume reduction and precision automation can reduce volumes of hazardous reagents used in processes, in addition to reducing unnecessary pipette tip usage.

Employing a low-volume protocol can further increase the number of reactions possible. This means using less reagent and reducing costs, in addition to having a lower environmental impact.

As supply chains encountered disruption from the COVID-19 pandemic, doing more with less became critical for those reliant on tips and reagents, such as diagnostic labs. Tips for the mosquito and dragonfly instruments are manufactured in the UK, guaranteeing a reliable supply chain to customers worldwide.

The COVID-19 pandemic has provided a unique opportunity to start fresh and address issues in line with a UN call for a greener post-pandemic world. In our attempts to compensate for lost time, we can build a more efficient and sustainable research environment for the future.

Future Outlook

Biology continues to be an under-industrialized profession, despite it being such an advanced field. Only lately have automated platforms and standardized DNA parts started playing a part in biology becoming a precision engineering discipline.

In Henry Ford’s day, standardized parts enabled the automobile to be accessible to the public, and even more so with the introduction of automation to the assembly line. This same hope exists for biology.

Automation can produce more efficient, replicable, and responsible research, improved by engineering-like precision and sustainable research practices in every field of biology.

About SPT Labtech

We Design and Manufacture Robust, Reliable and Easy-to-Use Solutions for Life Science

We enable life scientists through collaboration, deep application knowledge, and leading engineering to accelerate research and make a difference together. We offer a portfolio of products within sample management, liquid handling, and multiplexed detection that minimize assay volumes, reduce material handling costs and put the discovery tools back in the hands of the scientist.

At the Heart of What We Do

Many of our innovations have been born out of the desire to create solutions to existing customer problems; and it’s this ethos that drives SPT Labtech’s R&D efforts. Our strengths come from the trust our customers have with us to develop truly unique, automated technologies to meet their needs. We combine cutting edge science with first-rate engineering to put customers at the heart of everything we do.

A Problem-Solving State of Mind

The substantial breadth of expertise within our company enables us to be involved in the full life cycle of our products from the initial design concept, mechanical and software engineering and prototyping, to final manufacture and sale. These qualities allow us to offer the best possible technical and mechanical support to all the equipment that we supply, hence maintaining excellent client relationships.

Sponsored Content Policy: AZoLifeScience.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.