A skeptic may believe that pipettes are only helpful for the aspiration and dispensing of measured volumes of liquid. However, pipettes enable precise and timely data acquisition across various workflows and industry applications in a 'publish or perish' research culture.

The correct pipetting workflow can increase the probability of publishable results and substantially affect your career through enhanced precision, reliability, and ergonomic handling.

An overall shift toward higher throughput methods also means that automation is now accessible for many early career researchers. Manual pipettes no longer serve our needs, often causing repetitive strain and contamination risks. Instead, we look elsewhere for liquid handling satisfaction.

This article discusses the challenges of manual pipettes and how automated liquid handling solutions can be implemented to overcome these.

When did your pipettes last serve you?

Manual pipetting can quickly introduce user error due to incorrect volume settings, poorly fitting tips, and atmospheric pressure and temperature sensitivity.

Pipetting accuracy should lie within 3% of the expected weight or radioactive counts, while precision should lie within 2.5%.

Repetitive strain injury (RSI) describes the discomfort felt in nerves, muscles, and tendons caused by repetitive movement and overuse. RSI as a result of manual pipetting is not uncommon amongst researchers.

Studies have demonstrated that wet-lab scientists are at an increased risk of hand and elbow RSI than the general workforce, partly because of the burden of manual pipetting tasks.1,2

Assess Liquid Handling Needs

Automated solutions help improve the reproducibility, standardization, and efficiency of work.

Liquid handling needs must be considered. Sample type is one of the main factors affecting accuracy and precision (see Table 1).

Air displacement pipettes are best suited to aqueous liquids while positive displacement pipettes are more appropriate for volatile or viscous sample types. Filtered tips should be employed for the handling of biological materials.

Table 1. Pipettes for different sample types. Source: SPT Labtech

| Sample Type |

Example |

Recommended Pipette |

| Aqueous |

Water, buffers |

Air displacement |

| Biological |

DNA, plasma blood |

Air displacement with a filter |

| Viscous |

Glycerol |

Positive displacement |

| Volatile |

Organic solvent - methanol, ethanol, acetonitile |

Positive displacement |

| Hazardous |

Radioactive samples, infected blood samples |

Positive displacement |

| Corrosive |

Acids - e.g. hydrochloric sulphuric or bases e.g. ammonium hydroxide |

Positive displacement |

Liquid Size and Volume

The volume of liquid required to be moved will determine which pipettor is the right fit. Optimal sample volumes for automation usually range from 1 to 1000 µL, but some automated systems can attain nanoliter or even picoliter levels of accuracy.

Benchtop tasks within this liquid volume range include high-throughput screening, PCR preparation, and next-generation sequencing library preparation workflows.

Level of Independence

Liquid handling robots can outperform even expert operators. They enable increased throughput of most workflows and provide a flexible solution that allows you to concentrate on more value-adding tasks.

Whether you want to run multiple experiments in parallel or run more replicates per experiment, it is crucial to consider how your workflow may change with the introduction of automation and integration capabilities.

Return on Investment

The statement that automated or high throughput equipment must be a big commitment is false. The return on investment can be substantial despite the initial costs for automated pipettors being higher than their manual counterparts.

Both training commitments and unscheduled downtime can be significantly reduced by choosing a pipettor constructed with ease of use in mind.

Convince Your Lab Supervisor

Once you have assessed your needs and gained support, it is time to discuss pipetting solutions with your supervisor. Ensure you are prepared to address this conversation as respectfully as possible and offer a sense of resolution.

Be Honest

Do not be afraid to voice concerns surrounding repetitive strain if it impacts your workplace well-being. Many labs provide a temporary solution, such as a communal pipette bank. Be clear with your supervisor if this is an option you have already exhausted.

See Their Perspective

Your supervisor will be concerned with maintaining the efficiency and profitability of the lab, as well as the reproducibility and reliability of data.

Consider the costs and benefits of various liquid handling solutions and be prepared to share this knowledge. Highlight the advantages of standardization, accuracy, and the effect on your publication potential.

Concentrate on the Solution

Help your supervisor see that moving from manual pipettes can be an opportunity. Instead of comments like “My manual pipettes are old and broken”, perhaps try “An automated liquid handling system will keep our lab at the forefront of technology in the field”.

Give Your Colleagues the Heads Up

Contact your colleagues to let them know you are considering a change and propose a meeting to discuss this further. Explain the disadvantages of manual pipettes and the benefits of automated alternatives.

For many labs, compromising on valuable bench space may be an obstacle to automation. However, your lab manager will be supportive, with many pipettors now providing flexibility, convenience, and agility on a compact bench footprint.

Ensure that your colleagues understand what an enhanced integration capability and increased workflow agility could offer the group. With applications such as high-throughput screening, assay development, and cell-based and next-generation sequencing workflows, there is a solution for everyone.

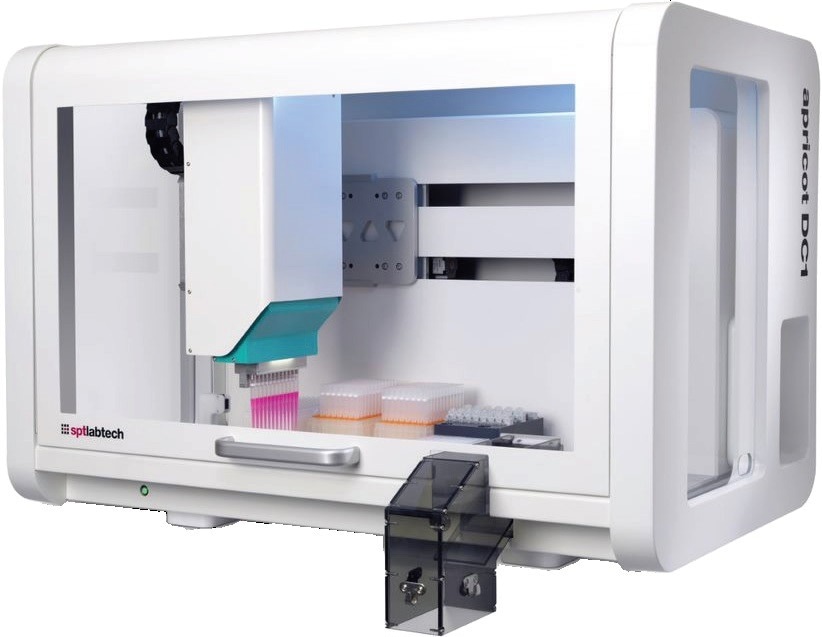

There is an apricot for Everyone

These advances in pipetting technology provide a huge opportunity for growth. The apricot range of liquid handling systems delivers reliability, high-performance, and can help you to realize your goals.

Each instrument remains compact and intuitive without prolonged ramp-up times, meaning you can begin your experiments immediately. Whatever your requirements, there is an apricot for everyone.

Taking the First Step Towards Automation

The apricot DC1 provides compatibility with a broad range of labware and customization with on-deck modules, including shakers, plate heaters, tip washing stations, or magnetic bead separators.

Dual low- and high-volume pipetting cores, together with accuracy across the 1-1000 µL range, make the apricot DC1 ideally suited to labs looking to scale up.

Image Credit: SPT Labtech

Accessible Solution with Integration Potential

The apricot S3 is both straightforward and flexible as the most accessible benchtop solution. An interchangeable 96- and 384-well pipetting core, adjustable plate elevators, and programmable serial dilution protocols make the apricot S3 ideal for various workflows.

It is smoothly integrated with other lab equipment, such as robotic arms, microplate stackers, and automation work cells, via a WiFi-enabled touchscreen interface and readily available API support.

Image Credit: SPT Labtech

Versatile All-rounder

The apricot S1 provides adjustable split-level plate elevators, an interchangeable 96- and 384-well pipetting core, and easy tip-loading technology. This means it is the most flexible liquid handler available.

More than 12 times faster than a traditional 8-channel handheld pipettor, the apricot S1 comes with EZ-Load disposable tips for high-speed, no-pressure loading.

Image Credit: SPT Labtech

Multi-functionality and High Performance

The apricot PP5 5 linear plate positions and tip wash/reservoir station make it the perfect option for boosting performance and throughput. The apricot PP5 reduces repetitive tasks, including plate reformatting and serial dilutions, eradicates manual pipetting errors, and maximizes results on a modest bench footprint.

Image Credit: SPT Labtech

Pipetting workflows demand a certain extent of flexibility, and an apricot pipettor certainly enables this.

With dual low- and high-volume pipetting cores that work with both 96- and 384-well configurations, apricot machines can facilitate many liquid handling tasks, including high-throughput drug screening and low-replicate gene expression analysis.

A variety of options regarding interchangeable integration are available, such as robotics, microplate stacking, and automation. This means that you and your pipettor will always have the capacity to scale up. An apricot machine can provide so much more support than manual pipettors.

An apricot engineer will be allocated to help you set up your new instrument upon purchase. Expert Field Application Scientists will also work with you to produce a customized demo plan. Demos involve colored dyes to help you and your colleagues visualize how each component works.

Finally, a post-demo discussion will offer guidance on protocol adjustments to enhance the quality and yield of results. Once you have selected your pipettor, your apricot will allow you to generate a lot of high-quality, publishable data.

Sharing your work in papers and at conferences will help you to establish a bond with your apricot. It could even encourage other young researchers to find the confidence to use automated liquid handling solutions.

References and Further Reading

- Björksten MG, Almby B, Jansson ES. Hand and shoulder ailments among laboratory technicians using modern plunger-operated pipettes. Appl. Ergon. 1994;25(2):88-94. doi: 10.1016/0003-6870(94)90069-8

- David G, Buckle P. A questionnaire survey of the ergonomic problems associated with pipettes and their usage with specific reference to work-related upper limb disorders. Appl. Ergon. 1997;28(4):257-62. doi 10. 1016/s0003-6870(97)00002-1

About SPT Labtech

We Design and Manufacture Robust, Reliable and Easy-to-Use Solutions for Life Science

We enable life scientists through collaboration, deep application knowledge, and leading engineering to accelerate research and make a difference together. We offer a portfolio of products within sample management, liquid handling, and multiplexed detection that minimize assay volumes, reduce material handling costs and put the discovery tools back in the hands of the scientist.

At the Heart of What We Do

Many of our innovations have been born out of the desire to create solutions to existing customer problems; and it’s this ethos that drives SPT Labtech’s R&D efforts. Our strengths come from the trust our customers have with us to develop truly unique, automated technologies to meet their needs. We combine cutting edge science with first-rate engineering to put customers at the heart of everything we do.

A Problem-Solving State of Mind

The substantial breadth of expertise within our company enables us to be involved in the full life cycle of our products from the initial design concept, mechanical and software engineering and prototyping, to final manufacture and sale. These qualities allow us to offer the best possible technical and mechanical support to all the equipment that we supply, hence maintaining excellent client relationships.

Sponsored Content Policy: AZoLifeScience.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.