Overview

The low cost, simple commissioning, and speedy delivery ensure a quick and smooth start to the rapid test production. The LFDA-1 can produce up to 24 components per minute while taking up less than 2.5 m² (less than 26 f²) footprint in the cleanroom.

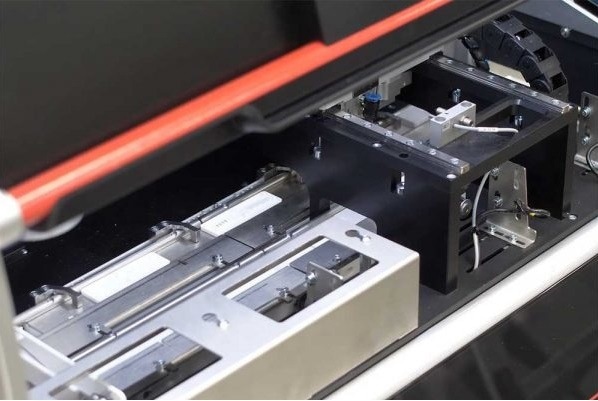

Ginolis LFDA-1 assembly system for lateral flow devices

Video Credit: Ginolis Ltd

Features

- Modular integration

- Up to 20 parts per minute

- Assembly system for lateral flow devices

- Easy commissioning

- Affordable

- Quick delivery

System layout

- Manual feeding of the cassette bottom and top

- Automated strip cut and place – the robot places the top plastic

- Cassette press and quality control

Image Credit: Ginolis Ltd

Functional description

- The operator manually feeds the cassette bottoms and tops to the conveyor

- The strip cutter trims and inspects the strip

- The scara robot installs the strip at the bottom of the cassette

- The vision system examines the strip’s direction

- The robot places the top cassette at the bottom

- The cassette top and bottom are closed by the press unit

- The final inspection of the finished product is performed by the quality control unit

- Quality-approved items are now available for usage

- Failed products are discarded in a reject bin

Image Credit: Ginolis Ltd

Technical specifications

Source: Ginolis Ltd

| . |

. |

| Capacity |

Up to 20 ppm, depending on machine configuration |

| Card infeed |

Automatic strip cutting and magazine buffer for laminated cards |

| Card length |

300-500 mm |

| Strip length |

40 – 98 mm |

| Infeed |

Manual bottom and cover feeding |

| Plastic parts |

- Width 15 – 40 mm

- Length 50 – 110 mm

|

| Connections |

- 230/110V 10A

- 6 bar (150 l/min)

|

| Optional features |

- Strip width QC

- Strip Bad mark automatic reject

- Press force adjustable 0-1000 N

- Integrated pressing height measurement during pressing

|

Fast tracking automated lateral flow production—working with LFDA-1

Ginolis LFDA-1 assembly system for lateral flow devices

Video Credit: Ginolis Ltd