Overview

The Ginolis Lateral Flow Device Assembly (LFDA) system is a standard system for fully automated fast test assembly and packing. The simplicity, adaptability, and innovative design enable a quick construction process.

Ginolis LFDA-6

Video Credit: Ginolis Ltd

- Intelligent: Vision-guided robot operation and quality inspection assure high quality

- Modular: Additional test strips, RFID tagging, printing, labeling, ultrasonic welding, cap assembly, and pouching are all possible with extra cells

- Flexible: The typical LFDA solution can assemble many test versions and products on the same line

Main features

- Quick product changeover due to minimal product specific parts

- Strip cutter with card magazine or reel infeed

- Compact design saves valuable space in clean room environments

- Machine vision guided infeed of materials

- Vision guided component placement, strip cutting, and assembly ensure consistent high quality

Image Credit: Ginolis Ltd

Other configurations

It is simple to install LFDA modules for multiple test strips, printing, RFID tagging, labeling, laser marking, ultrasonic welding, cap assembly, and pouching.

Image Credit: Ginolis Ltd

Housing infeed

Every LFDA system comes complete with a housing bulk infeed module. It can manage a wide range of house designs.

The bulk feeder mechanism has a programmable buffer that enables controlled and monitored infeed of housings.

Each housing is machine vision inspected to ensure it satisfies the quality control standards before being put on the carrier for transit to the following cell.

Image Credit: Ginolis Ltd

Intelligent transfer unit

On the Ginolis intelligent transfer system, components move along the LFDA system.

The multi-functional system moves the parts from module to module over a glass surface on magnetic carriers.

The intelligent transfer system requires less maintenance and has few exposed or moving elements.

Image Credit: Ginolis Ltd

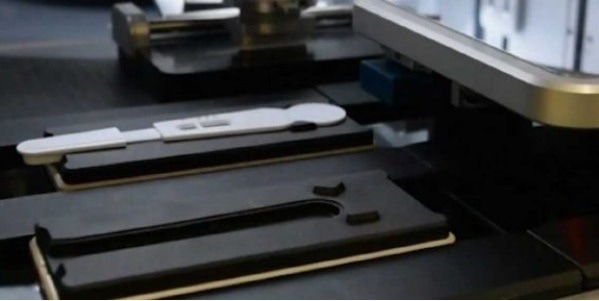

Strip cutting and assembly

The strip cutter module uses a linear servo motor-driven blade to cut the strips. You can get LFDA with a reel infeed or a card magazine.

The vision guiding system inspects for poorly marked material, accurate strip width, and the presence of pads prior to installation.

For test equipment with several strips, additional strip cutting modules can simply be added to the system.

Image Credit: Ginolis Ltd

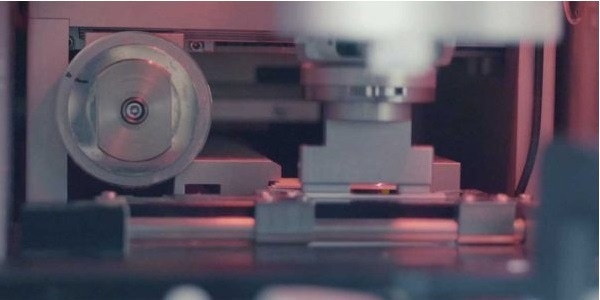

Press unit

The assembled lateral flow device is fed by a servo-driven press unit that has customizable press force and height characteristics.

After a successful cassette closure, the test apparatus is moved by the intelligent transfer system to the last quality inspection station.

Image Credit: Ginolis Ltd

Quality inspection

The LFDA system conducts the final quality control before packaging.

The component features, appropriate alignment, and cassette closing are examined by a number of cameras and dash lights.

Failed test gadgets are instantly taken off the production line. Another choice is a fluorescence light inspection.

Image Credit: Ginolis Ltd

Cap assembly

The test device’s cap is closed and attached to the end by the cap assembly module.

The cap is joined and the gadget is tested with a servo-driven press mechanism.

The cap assembly module comes standard with the bulk component infeed.

Image Credit: Ginolis Ltd

Ginger control system

- Ginger—desktop automation software

- Machine vision system

- GIN UX tablet user interface

- Supports multiple languages

- Embedded industrial PC (Win 7 Pro, Windows 10 IoT)

- USB, WLAN, LAN

Image Credit: Ginolis Ltd

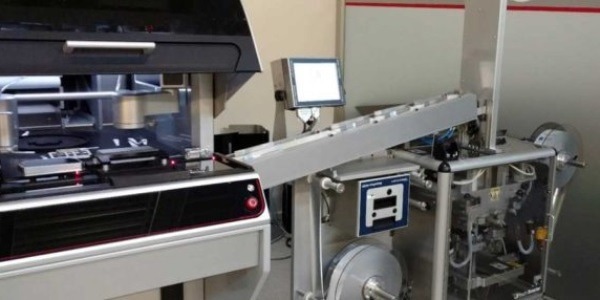

Third party equipment

Equipment from independent vendors can be combined with Ginolis LFDA solutions.

There are several possibilities, including pouching and kitting machines, labeling, printing, laser branding, and ultrasonic welding.

Image Credit: Ginolis Ltd