Overview

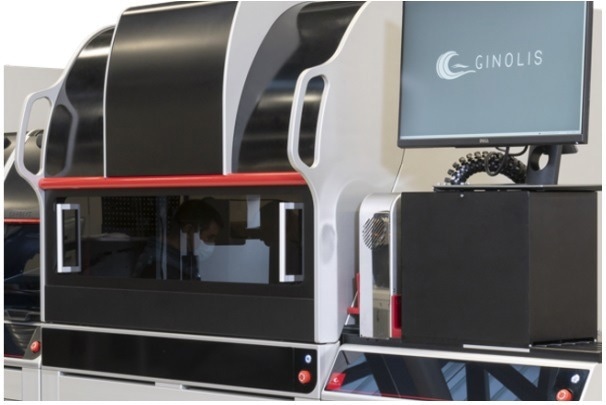

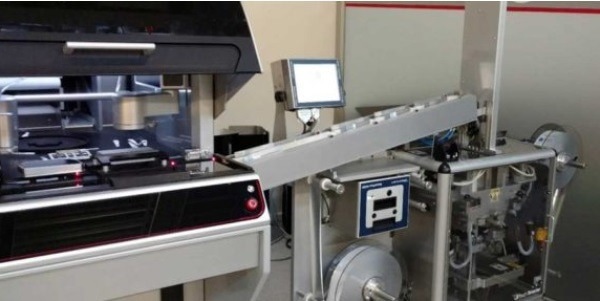

Ginolis Lateral Flow Device Assembly (LFDA) is a standard system for completely automated quick test assembly and packing. The modularity, flexibility, and clever design allow for an efficient assembly process.

Ginolis | Automated Lateral Flow Device Assembly Solutions

Video Credit: Ginolis Ltd

- Intelligent: High quality is ensured by vision guided robot operation and quality inspection.

- Flexible: The typical LFDA solution can assemble many test versions and products on the same line.

- Modular: Extra cells are available for additional test strips, RFID tagging, printing, labeling, ultrasonic welding, cap assembly, and pouching.

Main features

- Strip cutter with card magazine or reel infeed

- Machine vision guided infeed of materials

- Compact design saves valuable space in clean room environments

- Vision guided component placement, strip cutting, and assembly ensure consistent high quality

- Quick product changeover due to minimal product specific parts

Image Credit: Ginolis Ltd

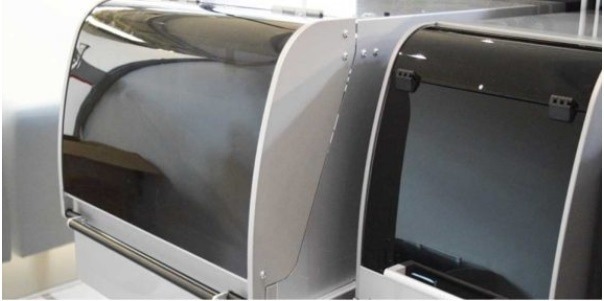

Other configurations

LFDA modules for numerous test strips, RFID tagging, printing, labeling, laser marking, cap assembly, ultrasonic welding, and pouching are simply added.

Image Credit: Ginolis Ltd

Housing infeed

All LFDA systems include a housing bulk infeed module as standard. It can handle a large variety of housing types.

The bulk feeder mechanism allows for regulated and monitored infeed of housings with a programmable buffer.

Before each housing is placed on the carrier for transportation to the next cell, machine vision inspection verifies it meets the quality control criteria.

Image Credit: Ginolis Ltd

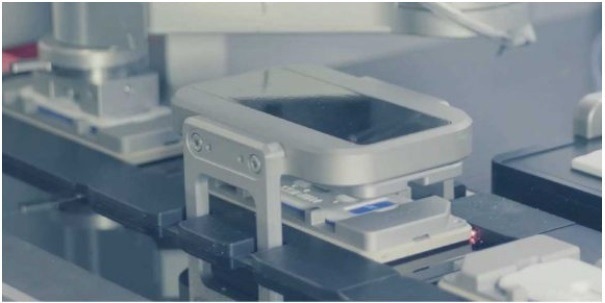

Intelligent transfer unit

The Ginolis intelligent transfer system moves components along the LFDA system.

The multi-functional system uses magnetic carriers to move components from module to module over a glass platform.

The intelligent transfer system is simple to clean and maintain because it has few exposed and moving parts.

Image Credit: Ginolis Ltd

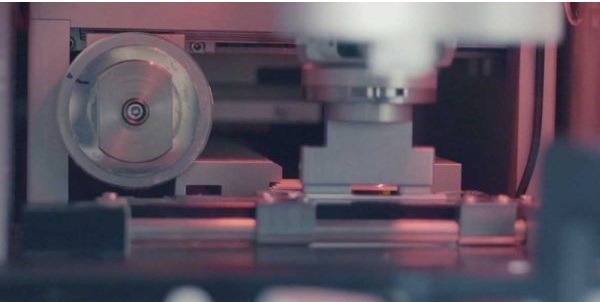

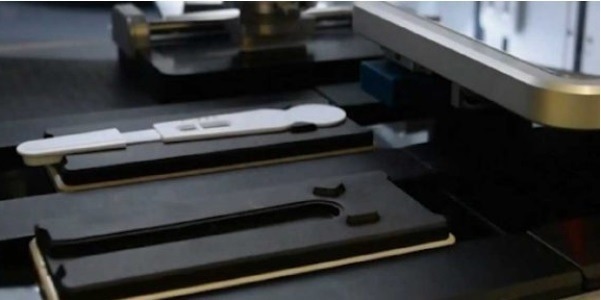

Strip cutting and assembly

To cut the strips, the strip cutter module employs a linear servo motor-driven blade. LFDA can be ordered with either a card magazine or a reel infeed.

Before installation, the vision guidance system checks for badly marked material, accurate strip width, and the presence of pads.

Additional strip cutting modules can be simply incorporated onto the system for test equipment having more than one strip.

Image Credit: Ginolis Ltd

Press unit

A servo-driven press unit with configurable press force and height parameters feeds the assembled lateral flow device.

Following successful cassette closure, the test equipment is transported to the final quality inspection station via the intelligent transfer system.

Image Credit: Ginolis Ltd

Quality inspection

Before packaging, the LFDA system performs the last quality inspection.

Several cameras and dash lights inspect the component features, proper alignment, and cassette closing.

Failed test devices are automatically removed from the assembly line. A fluorescence light inspection is an additional option.

Image Credit: Ginolis Ltd

Cap assembly

The cap assembly module attaches the cap to the end of the test device and closes it.

A servo-driven press mechanism is used to join the cap and test the device.

The bulk component infeed is standard with the cap assembly module.

Image Credit: Ginolis Ltd

Ginger control system

- Ginger—desktop automation software

- GIN UX tablet user interface

- Embedded industrial PC (Win 7 Pro, Windows 10 IoT)

- Machine vision system

- USB, WLAN, LAN

- Supports multiple languages

Image Credit: Ginolis Ltd

Third party equipment

Ginolis LFDA solutions can be integrated with equipment from third-party vendors.

Pouching and kitting machines, labeling, printing, laser branding, and ultrasonic welding are all options.

Image Credit: Ginolis Ltd