Overview

The innovative plate washer from Cytena, called C.WASH™, was created for fully automated, quick, and highly reproducible washing of 96-, 384-, and 1536-well plates.

The C.WASH™ uses centrifugal forces to quickly remove liquids, by being contactless, from well plates. One of the four liquid input channels should be used to dispense liquid onto the plate. The dispensing angle permits aiming at well walls, protecting pellets of magnetic beads, bound capture antibodies, or growing cells.

The non-contact washing saves on pipette tips while lowering the risk of carry-over and cross-contamination.

C.WASH™ is the ideal option for bead-based nucleic acid purification and cell-based assays because of these special qualities.

Features

- Non-contact washing

- Utilize liquid removal and non-contact dispensing to reduce the risk of carryover and cross-contamination

- Supports multiple plate sizes

- A versatile tool that can delicately remove liquid from 96-, 384-, or 1536-well SBS plates of any format

- Low residual volume

- Unmatched washing efficiency, requiring fewer cycles with residual volumes of only <0.1 µl

- DNA purification

- Magnetic plate carriers allow for quicker NGS library preparation

- Fast and automated

- One wash cycle in a 96- or 384-well plate, fully automated and standalone, takes about a minute

TIP Consumption Calculator

- Dependence on pipette and liquid handler tips has a negative financial and environmental impact

- Using only pipette tip savings, users can quickly recover the cost of a C.WASH by using the Tip Consumption Calculator to determine how many tips they use annually

-

Application

- The C.WASH™ washing efficiency increases assay efficiency while reducing costs, shortening turnaround times, and improving the reproducibility of results

Image Credit: Cytena

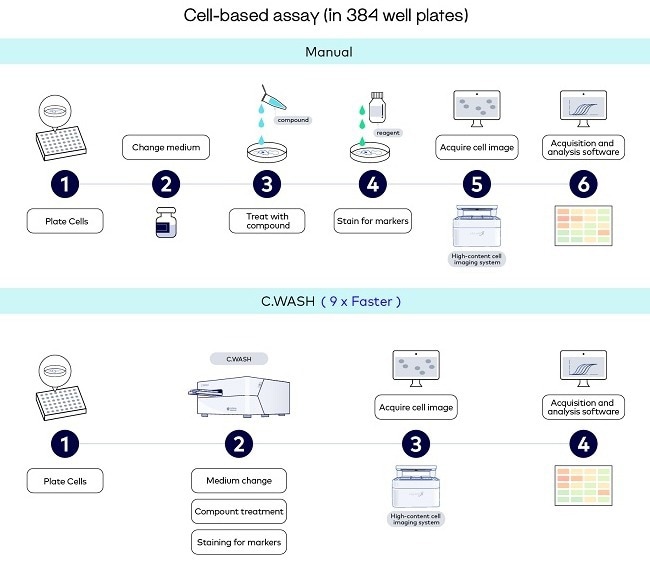

Cell-based assays

Image Credit: Cytena

- Since C.WASH automates every washing and dispensing step in a typical screening workflow, it is a crucial tool for gene editing or drug discovery in HTS settings

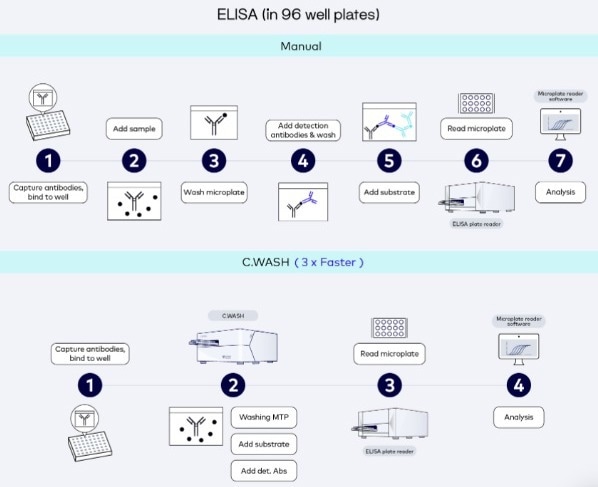

Immunoassays

Image Credit: Cytena

- Due to the high sensitivity of ELISA immunoassays, cross-contamination and/or inaccurate pipetting may result in a high coefficient of variation (CV)

- The precise non-contact dispensing reduces cross-contamination by limiting

- The reduced residual volume after washing allows for improved washing efficiency and fewer washings

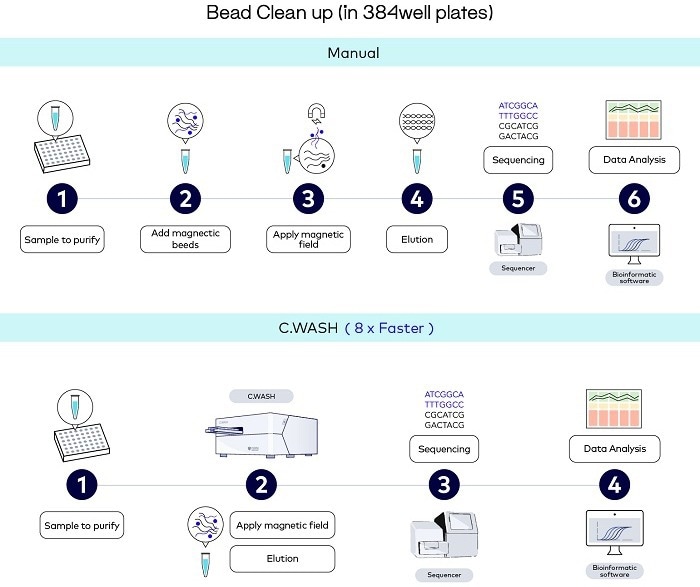

DNA purification

Image Credit: Cytena

- The ideal method for creating NGS libraries now involves using beads to clean DNA

- The popularity of single-cell sequencing and the lower cost of high throughput sequencing have significantly increased the sample that must be processed, even though it is a quick and simple method

- Thanks to the compatible Magnetic plate carriers, the C.WASH can automate this workflow in both 96 and 384 microplates

Highly reproducible washing efficiency

- C.WASH, which has a residual volume of <0.1 µL/well, significantly lowers the number of wash cycles needed and produces quicker, more reliable assays

- 99.5% after 1 wash cycle

- 99.99% after 2 wash cycles

Services

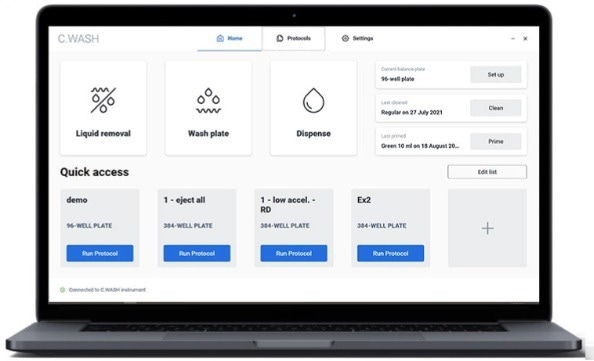

- The C.WASH software was created with simplicity in mind, and its automation helps users save time

- The C.WASH ensures user efficiency by providing quick access tabs and an intuitive design

- This innovative plate-washing technique increases assay efficiency while lowering costs, speeding up turnaround times, and improving the reproducibility of results

Intuitive user-friendly software

Image Credit: Cytena

- This is the system’s defining characteristic and offers a special competitive advantage in the market

- The software’s ease of use makes it possible to guide users through each step of their protocol

Creation of customized programs

- The user can select from a number of options, including pause time, shaking, decanting, and centrifugation time, with the feature they value the most

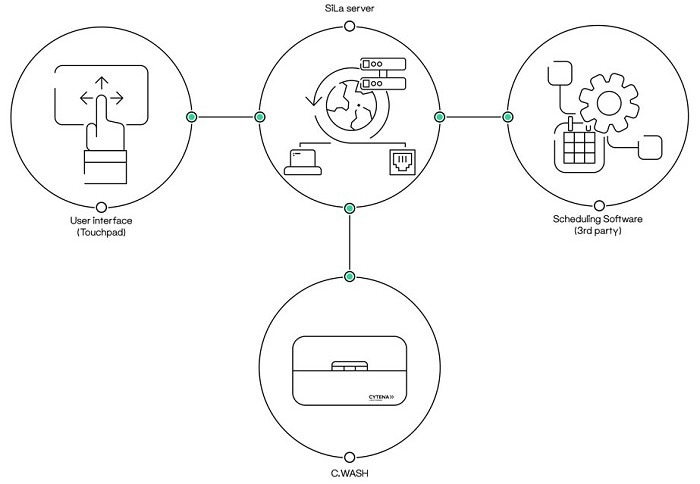

Automation-friendly software architecture

Image Credit: Cytena

- The Standardization in Laboratory Automation (SiLA2) interface’s well-documented communication allows integration with automation programming interfaces and is compatible with third-party control software

- Being SiLA2 compliant makes the C.WASH easier to integrate into HTS facilities

Waste system in C.WASH™

Image Credit: Cytena

- Liquid inputs

- Internal auto-switching for up to four liquid input channels with auto-priming capability

- Waste system

- An active pump is used to remove the waste, preventing internal tubing clogging in the process

- As it permits integration in any lab setup, it also reduces the instrument footprint