Overview

The BioShake Q1 from QInstruments is a professional heater–cooler shaker for 48/96/384 well microplates.

Key benefits

The BioShake Q1 is known to be the perfect and highly efficient thermoshaker that is available for 48/96/384 well microplates. The improved orbital mixing system and mass balance elements decrease noise and vibrations considerably at the time of cooling, heating, and mixing of fully loaded plates.

Completely adjustable between –20 °C and 99.9 °C and well beyond the cooling and heating precisions of a majority of the other brands, Q1 ensures outstanding temperature control for every application.

The patented locking mechanism ELM seals the microplates in a rapid and safe manner, even at the greatest mixing frequencies. Quick mixing processes with regular plate changes could be executed in the routine as simple and safe.

The Q1 module is just a little larger compared to a standard microplate.

All parts are within the unit, and no external components are unnecessary.

Features

- Cooling and heating, mixing in a single unit

- Quick mixing ranges from 200 up to 3,000 rpm

- Completely adjustable between –20 to 99.9 °C

- Plate locking ELM ± 0.1 mm

- Cooling or heating speed 12 K/minute above RT

- Temperature range 24 K below RT, max: 99.9 °C

- Sensored zero-position ± 0.1 mm

- Extensive range of developed thermo adapters

- No additional external electronics

- No maintenance required for many years

- Stylish aluminum housing is given

- Two years full warranty

- Simple installation and simple start-up

- Trustworthy Peltier technology in the absence of coolant

Advanced technology

Save time

By integrating the mixing operation with the help of the incubation phase, reaction process times and operator workload are decreased and the efficiency of several procedures is increased, leading to greater throughput.

The exceptional finished aluminum housing offers the BioShake Q1 its necessary functionality. It offers a high amount of safety, device stability, and guarantees a long service life.

Image Credit: QINSTRUMENTS GmbH

Gentle mixing of samples

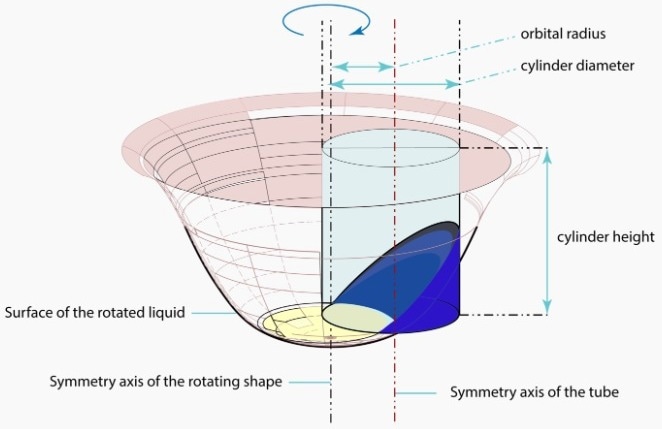

By planar orbital motion

German-developed and manufactured, BioShake Q1 thermoshaker provides an ultra-efficient, 2-dimensional shaking axis so that samples tend to get fully mixed in a fraction of the time of competing systems.

The mixing orbit of 2.0 mm is frequently constant. Indeed, the orbital shaking is accurately controlled, so that users never need to spin down their plates after mixing.

Completely adjustable between 200 and 3,000 rpm, far beyond the speeds of most other brands, ensures quick, splatter-free, mixing for tubes, glass vials, or throughout a full 96-well microplate.

Image Credit: QINSTRUMENTS GmbH

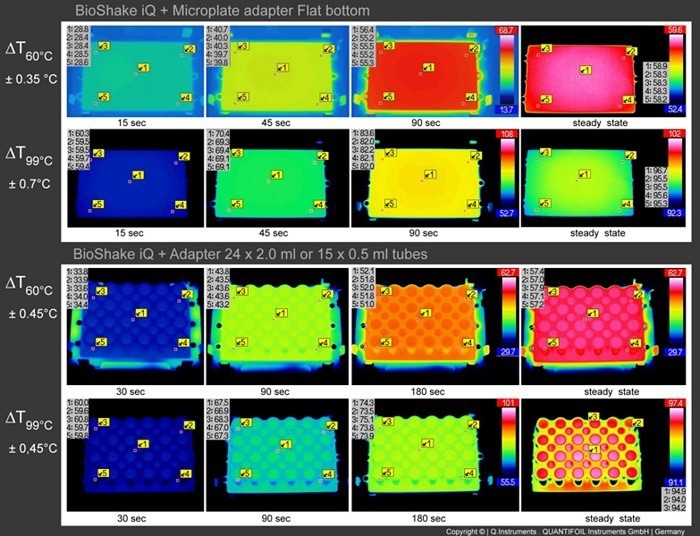

Homogeneous cooling and heating

Using of powerful Peltier element technology

Several lab experiments need quick heating and cooling steps in a highly precise manner in the range of –20 °C up to 99 °C. Accurate temperature control has been obtained for Q1 by making use of optimally balanced heating and cooling elements. The novel Peltier technology combined with fewer electronics and trustworthy algorithms guarantees a long useful life in every lab automation project.

BioShake Q1 is the perfect device of choice to precisely set and maintain temperatures. The module is just slightly larger compared to a standard microplate. Completely adjustable between –20 °C and 99 °C and well beyond the cooling and heating precisions of most other brands, Q1 ensures outstanding temperature control for tubes, vials, and microplates.

All parts inside, only a PC is required for control.

Temperatures are chosen from –20 °C to 99 °C in steps of 0.1 °C. The nominal regulation precision is better than ± 0.2 °C with uniformity of temperature distribution improved than ±1.0 °C at 4 °C throughout the cooling surface.

Interchangeable thermos adapter plates and thermal blocks allow an ideal adaptation to microplates, glass, or tube vials.

Image Credit: QINSTRUMENTS GmbH

Patented edge locking mechanism

Suitable for all microplates

Several robotic applications need accurate dimensional spacing of pipet tips and robotic grippers compared to a microplate. The Edge Locking Mechanism (ELM) is the full answer for repeatable and precise positioning of microplates present on a robotic deck. It comprises 2 × 2 stainless steel pins and a 2-point electromechanical mechanism to close down microplates in a safe manner in the module’s center.

This patented locking mechanism seals the microplates in a quick and safe manner, even at the greatest mixing frequencies. Quick mixing processes happening with regular plate changes could be executed in the routine as simple and secure.

For the gripping of microplates, the ELM sets the stage for the clamping to be in an automatic manner. This so-called “universal” design is ideal for all kinds of plates in SBS format 127.7 × 85.5 mm: from low profile to deep-well; from 96- to 1536-well. Also, when “locked” into place, the microplate changes by as little as +/− 0.1 mm making exacting manipulations a breeze.

Image Credit: QINSTRUMENTS GmbH

LED indication light

Simple status monitoring

All BioShake devices consist of sophisticated internal algorithms and sensors for tracking operating parameters and error detection. Any errors are sent out through the RS232 communication interface. Those are simpler to detect and localize.

To enhance the functional testing at the time of installation and visualize the operating status all BioShake automation devices have been fitted with one combined LED indication light in front. The indication light enables a rapid function test and error control.

This consists of a green and red status that light up either, or are invalid. In anticipation of failure, the error list should be read out through the RS232 command, to help detect the error in a highly accurate manner.

Image Credit: QINSTRUMENTS GmbH

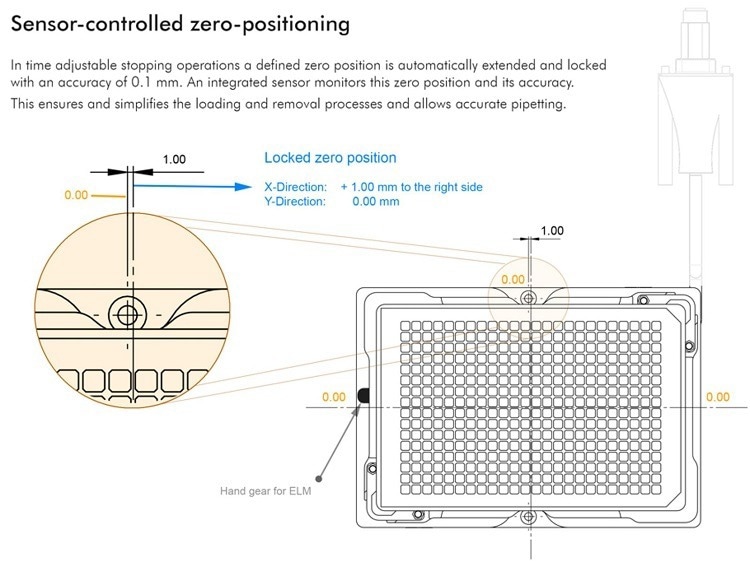

Zero position

Locked and sensor-controlled zero-positioning

In time-adjustable stopping operations, a defined zero position has been extended automatically and then locked with a precision of 0.1 mm.

A combined sensor tracks these zero positions and their precision. This guarantees and eases the loading and removal processes and enables precise pipetting.

Image Credit: QINSTRUMENTS GmbH

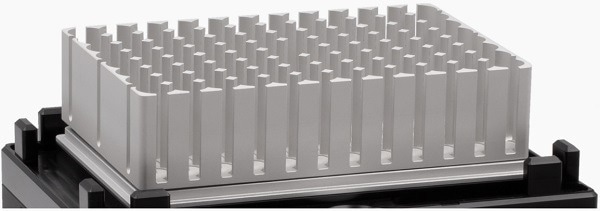

Exchangable thermo adapters

For a wide range of applications

The BioShake Q1 is available with a range of standardized and particular thermo adapter plates. The substitution of the adapters is very simple.

Perfect-shaped adapters enable an improved fit for lysis tubes, microplates, standard tubes, glass vials, and other sample vessels. Outstanding temperature uniformity and homogeneity have been ensured for all samples.

Image Credit: QINSTRUMENTS GmbH

Comfort

Simple intuitive integration in robots and programming

The BioShake could function through RS232 or USB user interface. An automatic initialization will commence after turn on.

An easy command set enables users to easily control sensors and hardware. The process parameters are continuously regulated and read out. A self-setting zero position of the shaker plate following turning off makes the laborious electrical tracking needless. This guarantees the utmost operating security also in unmonitored constant operation.

Unique design meets high-end technology

<First-class finished aluminium housing

The special and efficient design is integrated with the smallest housing outcome in beautiful and well-defined laboratory equipment. Hence, the first-class finished aluminum housing provides the BioShake Q1 with its vital functionality. It offers a high amount of security, and device stability and guarantees long service life.

Safety of the user and ease of use are clearly a priority.

Image Credit: QINSTRUMENTS GmbH

Made in Germany

High-end instruments for daily routine

An ideally harmonious blend of high-tech and handmade. “Made in Germany” has always been a recipe for triumph for QInstruments. 100% of QInstruments production occurs in Germany.

The focal point is on human perseverance and on being eco-friendly. The company supports its quality guarantee through comfortable quality management. For over 15 years such laboratory automation professionals from Jena have utilized only high-quality materials to guarantee tenable production, applied ground-breaking thinking, and initiated research in a future-oriented method—all as a matter of course.